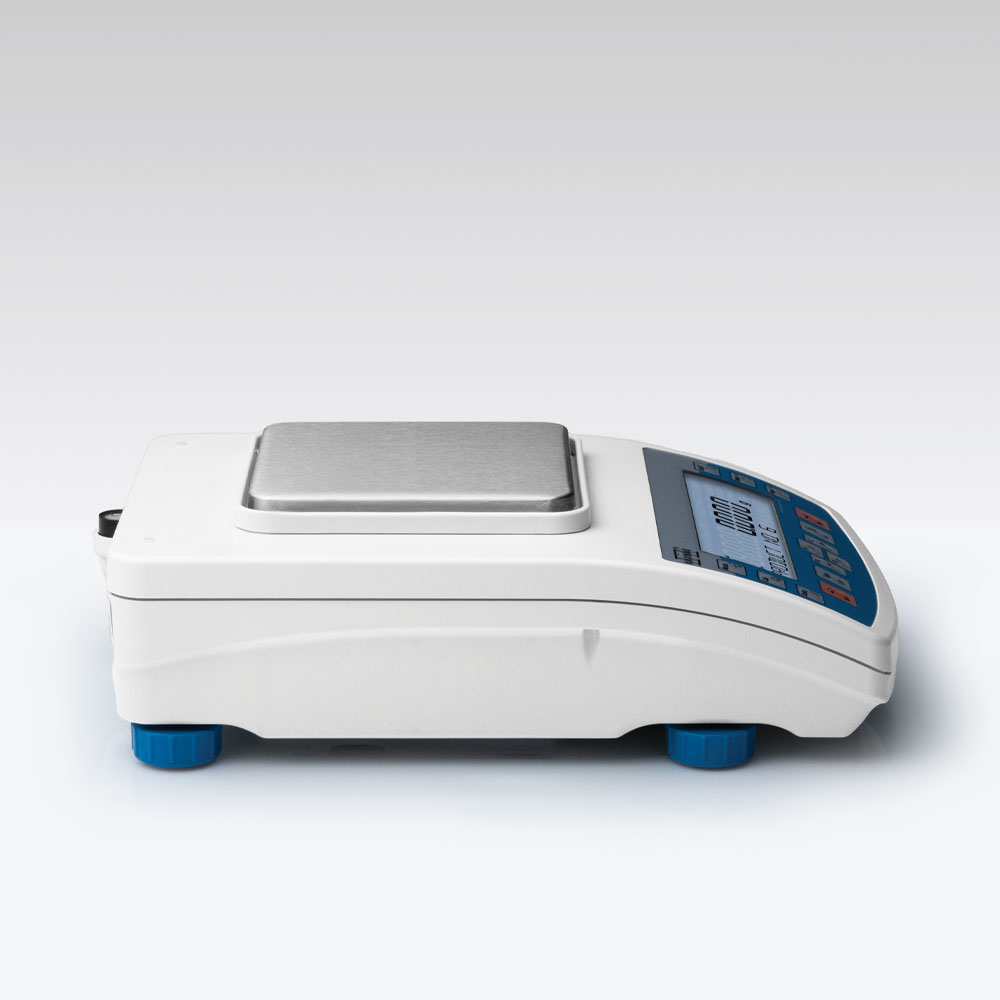

PS 750.R2 Precision Balance

a clearer presentation of the weighing result. Besides, the display has a new text information line allowing to show additional messages and data, e.g. product name or tare value.

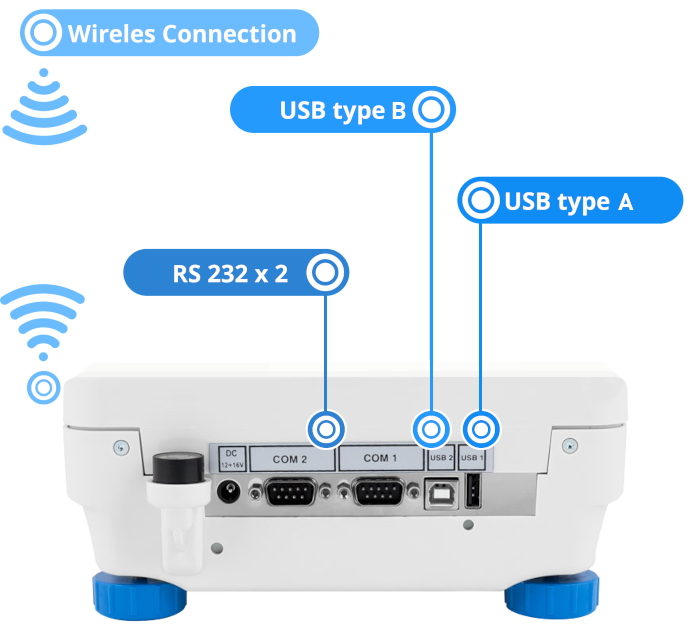

Communication interfaces

PS.R2 balances feature several communication interfaces: 2 x RS 232,

type A USB, type B USB and optional Wireless Connection.

The housing is made of plastic, and the pan is made of stainless steel.

Databases in R Series Balances

The data is registered in 5 databases:

- users (up to 10 users),

- products (up to 1000 products),

- weighments (up to 5000 weighments),

- tares (up to 100 tares),

- ALIBI memory (up to 100 000 weighments).

Quick access to information

Direct access to functions and databases is possible from the level of keyboard.

- Database - a direct access to databasis

- Function - a direct access to the basic functions

- F1 do F4 - programmable function and navigation keys on the menu

100 000 weighment records. It ensures security of constant data register in the long time period.

Learn about the use and maintenance of stainless steel products:

Stainless Steel in RADWAG products. Standard and special applications

Additional fee

Additional fee

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文