Precision Balance WTC

Fast and accurate mass determination both in the lab and in the factory. Energy-efficient electronics and display, combined with an internal rechargeable battery, are the perfect duo to allow you to work without access to mains power.

Precision not just in the name

When we designed this balance, we took care of the smallest details – both those you can’t see, hidden in the solid housing, and those you can touch. This balance is the result of a combination of our experience and true precision.

The power of steel

The use of stainless steel for the pan guarantees you a long life for the balance. It is not afraid of contact with moist objects or accidental splashes.

Time counts

The balance is equipped with a real-time clock that provides accurate time measurement in a way that is independent of external power supply.

It has been with us for years, and will stay for a long time to come

The LCD display has accompanied us for long years. During this time it has proven its reliability. It guarantees the readability of the result from many angles and is energy efficient.

Internal power

No access to mains power? Power failure? No problem. The internal rechargeable battery combined with the energy-saving display and electronics allow many hours of operation without mains power.

Anything else?

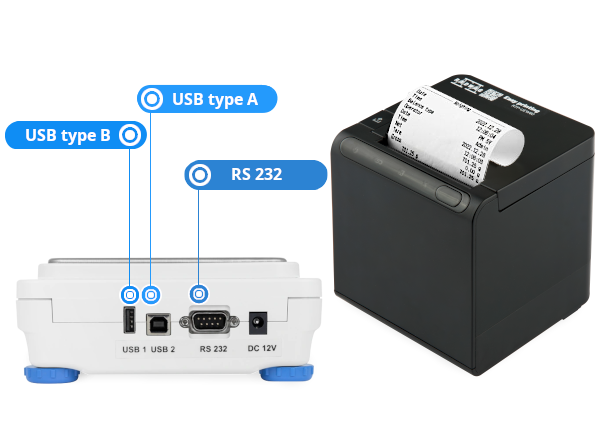

Plenty! Printer, computer, USB flash drive, additional display – the WTC balance can work with them through communication interfaces. In addition, a real-time clock and ALIBI memory. You can find all accessories in our regular offer. And if you have questions about compatibility, our experts will help you.

Do you need ALIBI?

There you have it. ALIBI memory is like a black box of a balance. It records all measurements taken on the device. The ALIBI memory cannot be modified or erased.

THBR 2.0 System

Cooperation with THBR 2.0 System for ambient conditions monitoring.

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文