PUE HX7 terminal is a constructional component of industrial multifunctional load cell scales, equipped with either one or numerous load cells. It is based on the latest solutions and an advanced computing platform. Versatile terminal’s software will satisfy even the most demanding users and system integrators. The basic version of the terminal features a vast range of communication interfaces, which range can additionally be expanded.

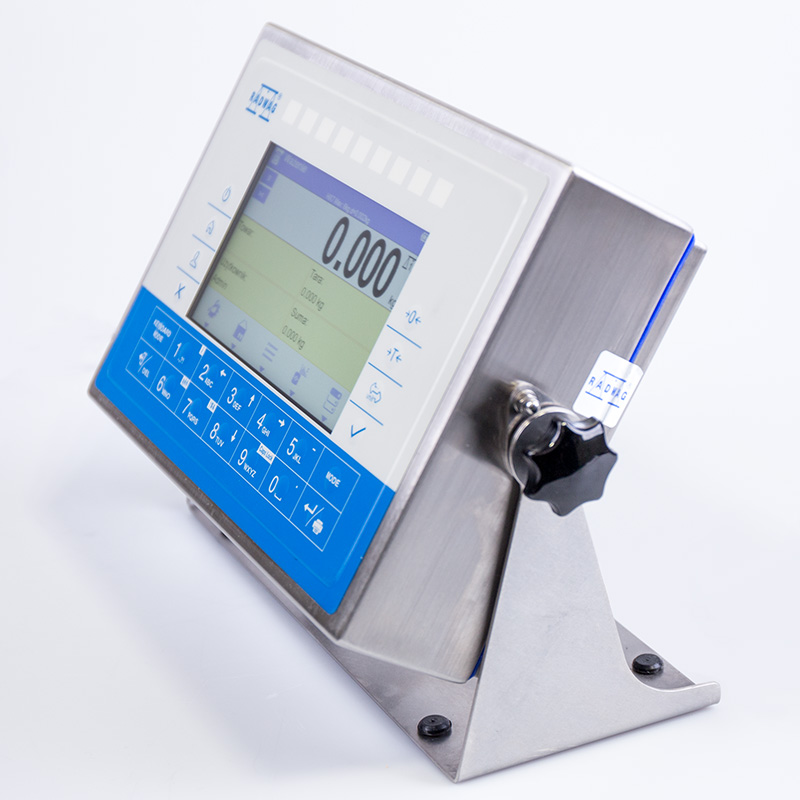

Housing

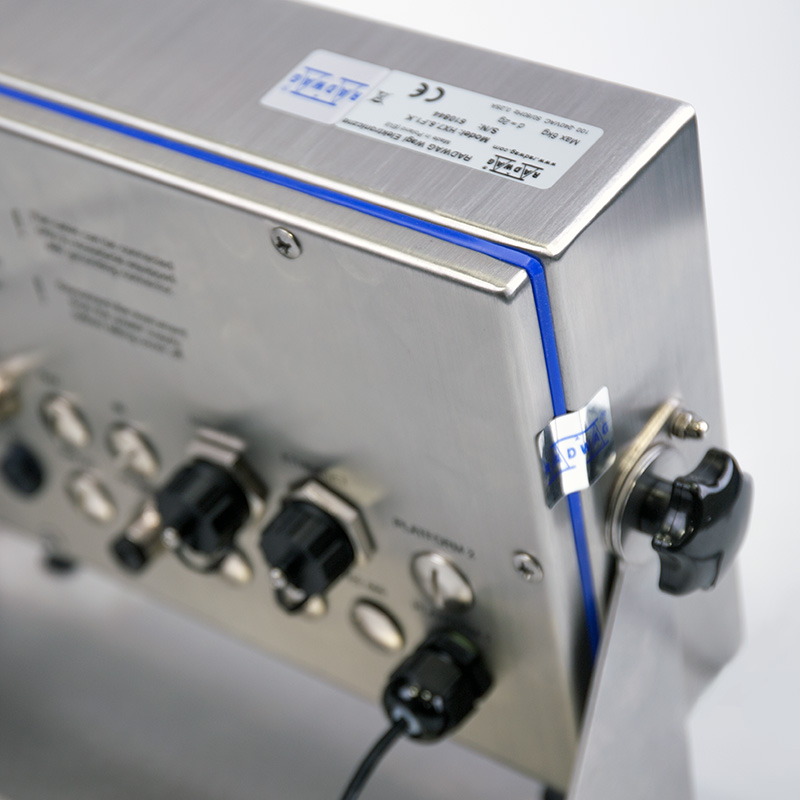

The housing, made of AISI 304 stainless steel, ensures high ingress protection, IP66 / IP68. The terminal is equipped with 7” colour LCD display and membrane keyboard. Ease of operation, clear menu and intuitive information arrangement on the display guarantee comfort of operation. Hermetic communication interface connectors are located on the back side of the housing. Stable mount bracket enables to mount the terminal either on a flat horizontal surface or on the wall. The device tilt can be easily adjusted.

Weighing Platform Operation

Basic version of the terminal supports 1 analog weighing platform. The possibility to install an additional weighing module enables to support 2 weighing platforms.

Diodes

Diode bar graph is located on the top of the operation panel and consists of 9 red and green diode fields. The terminal features 3 working modes: 'linear', 'weighing thresholds signalling' and 'checkweighing'. The bar graph significantly increases the comfort of operation during piecework in food industry when fast and unambiguous presentation of product mass deviation against the declared min and max values is crucial.

Multifunctional Software

Terminal software facilitates processes such as weighing, parts counting, dosing, labelling, formulations and percent weighing. Terminal’s information system is based on databases (such as: users, products, weighings, packaging, formulations, customers) and ALIBI memory which guarantees stored data safety.

When developing the software, special attention was given to the functionality and ergonomics. This resulted in increased comfort of terminal operation.

Optional Power Source from Internal Battery

Use of the optional battery enables the PUE HX7 terminal to operate even when there is either no or unstable power supply. This improves the security of acquired data and improves comfort of operation.

Communication Interfaces

The terminal is equipped with RS 322, RS 485, USB, Ethernet, digital inputs/outputs and analog output. This enables connection with external devices such as barcode scanners, printers, external displays, control buttons, light signalling towers, other controlling/signalling devices, systems for automatic process control and superior IT systems. The connection is possible due to the implemented and complex character-based communication protocol. In the future, the interfaces will be extended with Profibus and Profinet. Additionally, Modbus RTU and TCP protocols will be implemented.

PUE HX7 in a Version Powered from a ZR-03/2 Buffer Power Supply

The terminal can operate even though there is no access to a power source in a special design with power supply from an external buffer power supply ZR-03. The special design consists in modifying the standard version of the PUE HX7 terminal to a variant of this terminal adapted for power supply from a buffer power supply ZR-03/2. The ZR-03/2 set includes a voltage converter and a powerbank.

In a special design, the PUE HX7 weighing terminal has a 12-24V DC power socket to which the dedicated ZR-03/2 buffer power supply can be connected. The terminal can be powered only from the ZR-03/2 buffer power supply, not from the 110-230V AC mains or the internal battery. The powerbank can be charged using an external charger, after disconnection from the weighing terminal. The powerbank runs on one set of batteries while the other is charging.

The maximum operating time for the HX7 terminal is 20 hours, and the average is 12 hours. The operating time depends on the number of connected peripherals and the power drawn from the terminal.

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文