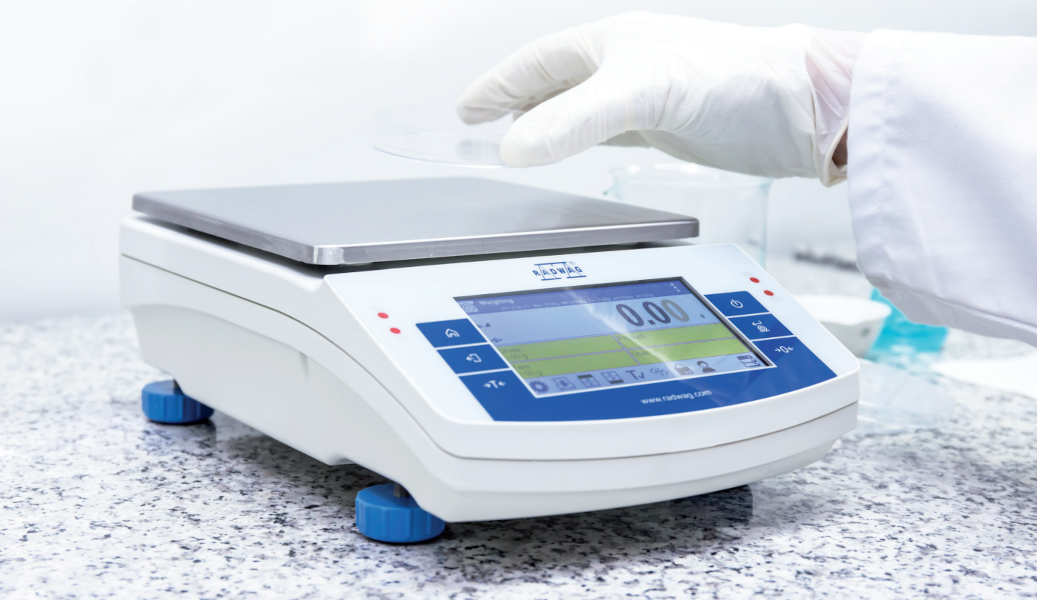

PS 750.X2 Precision Balance

Series PS.X2

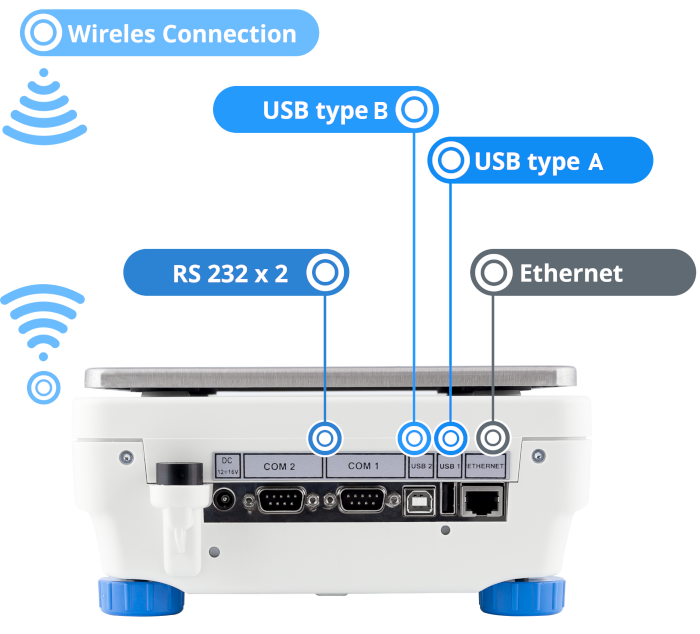

The X2 series balances feature the latest generation capacitive display providing the maximum comfort of use, available right at your fingertips. Ease of operation, clear menu and practical arrangement of the display guarantee the best ergonomics for your everyday tasks. A wide array of available interfaces facilitate selection of the most optimal means for communication.

Personalization taken to the next level

The X2 series balances offer unlimited possibilities for cooperation with external devices, providing printing, copying, archiving and data transfer.

Built-in IR sensors allow numerous operations (e.g. tarring, transmitting the result to a printer or selecting successive steps of a particular process, etc.) to be performed handsfree, by simply moving a hand across the sensor. The housing is made of plastic, and the pan is made of stainless steel.

Databases in X2 series balances

The data is registered in 9 databases:

- Products (5 000 products)

- Users (100 users)

- Packaging (100 packaging types)

- Customers (1 000 customers)

- Formulations (100 formulations)

- Formulations reports (500 reports)

- Ambient Conditions (10 000 records)

- Weighings (50 000 records)

- ALIBI memory (512 000 records).

Weighing Data Management

ALIBI Memory

The ALIBI memory allows to record up to 500 000 weighment records.

Learn about the use and maintenance of stainless steel products:

Stainless Steel in RADWAG products. Standard and special applications

Check the price in our store

radwaguk.com

Buying from the producer is all about the pros

You always get the latest version of the device and software. We are constantly improving our products.

Technical support from the product developers. Who better to know the answers to your questions? Like our Facebook – profile – stay in touch with us.

A solidly packaged shipment travels only one way – the one to you.

In our permanent offer you will find accessories for our balances and scales, such as cables, weighing pans and power supplies, as well as all spare parts. And we carry out legalization and periodic inspections in our laboratory.

You buy a product developed and manufactured in Europe – you get a device with a certain standard of compliance.

Additional fee

Additional fee

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky Português (Brasil)

Português (Brasil) USA

USA 中文

中文