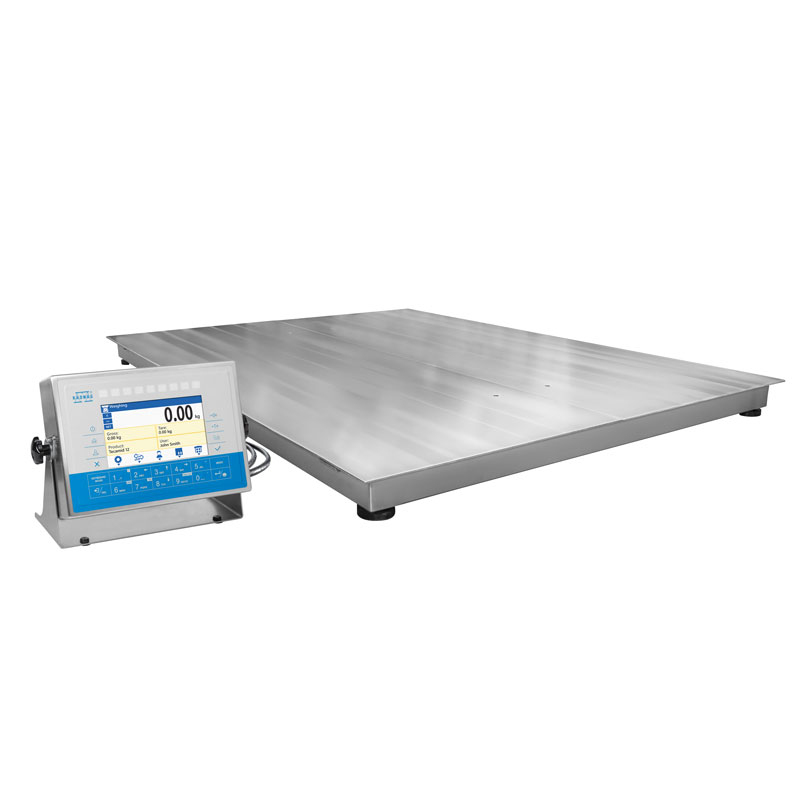

HX7.4.300.H9 Multifunctional Stainless Steel Platform Scale, pit version

4 load cells guarantee correct weighing regardless of load placing at the platform.

Equipment

This enables cooperation with external devices such as:

- barcode scanners,

- printers,

- external displays,

- control buttons,

- light signalling towers,

- controlling/signalling devices,

- systems for automatic process control,

- superior IT systems.

Databases

- users,

- products,

- weighings,

- packaging,

- formulations,

- customers,

- ALIBI memory which guarantees stored data safety.

Learn about the use and maintenance of stainless steel products:

Stainless Steel in RADWAG products. Standard and special applications

Additional fee

Additional fee

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文