- the ability to weigh loads up to 150 kg on a large weighing pan with high accuracy and good repeatability,

- minimum eccentricity error over the entire range,

- quick and stable measurement (achievable within 1 second),

- parameter stability over time and during transport,

- weighing pan dimensions adapted to the accuracy of the balance.

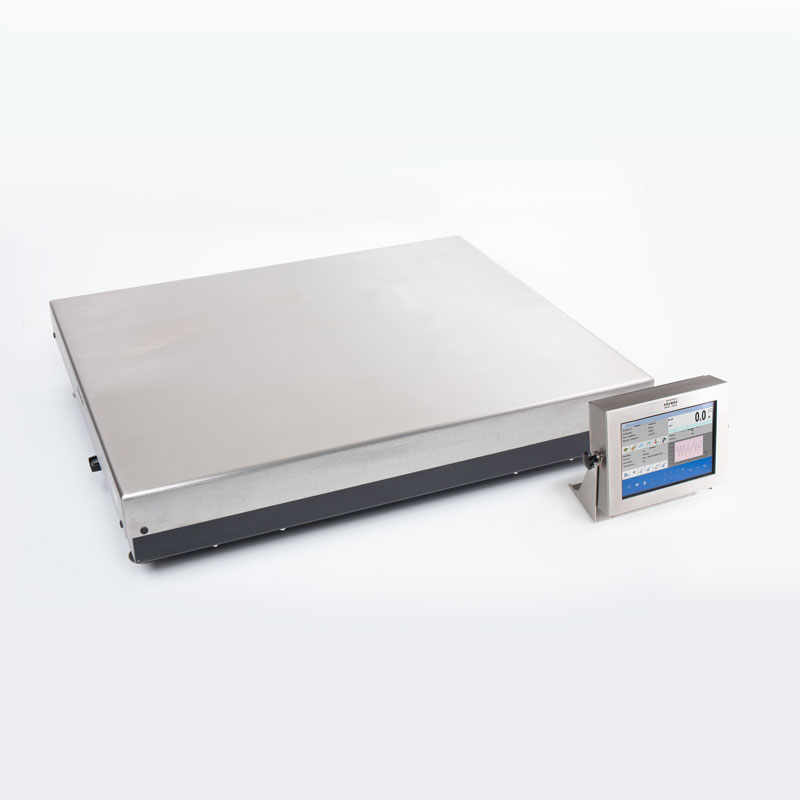

MONO

BLOCK® technology.The new, taller and larger

MONO

BLOCK® enables the best repeatability and speed in its class of high resolution industrial weighing platforms.- 5.7”, resistive, colour display,

- touch-sensitive keypad,

- ABS housing,

- IP 43,

- communication interfaces: RS 232 (2), USB-A (2), Ethernet, IN/OUT (4), Wi-Fi®,

- optional extra modules: module of an additional A/D DP6 converter.

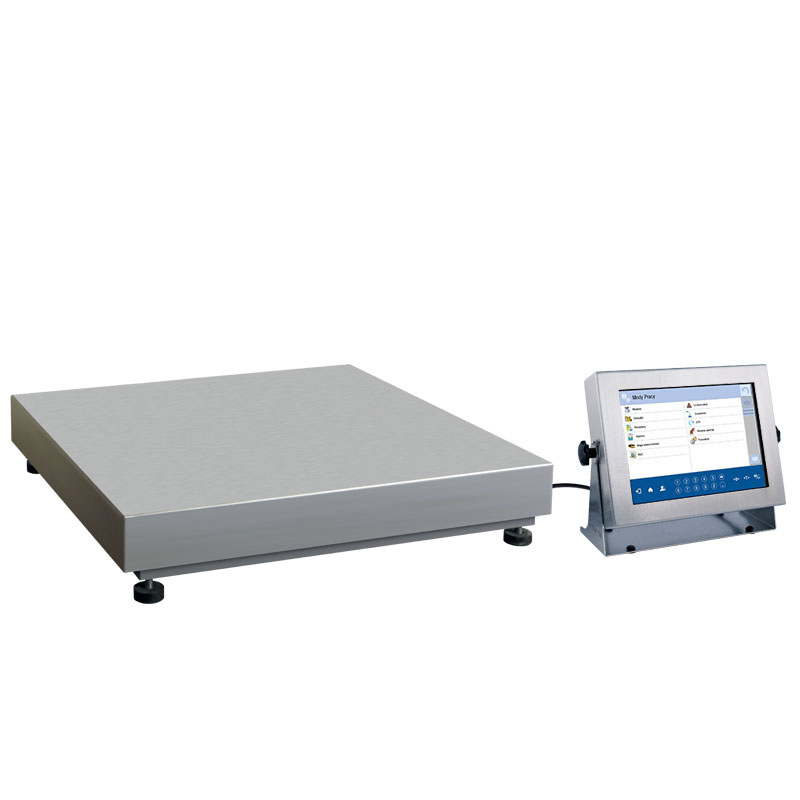

- 10.1”, graphic, colour display,

- touch-sensitive keypad,

- stainless steel housing,

- IP 68/69,

- communication interfaces: RS 232 (2), USB (2), Ethernet, IN/OUT (4),

- optional extra modules: Wi-Fi®, RS 485, Profibus, Profinet, analog output module, IN/OUT (12).

Learn about the use and maintenance of stainless steel products:

Stainless Steel in RADWAG products. Standard and special applications

Wi-Fi® is a registered trademark of Wi-Fi Alliance®.

Extra payment

Extra payment

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Deutsch

Deutsch English

English Español

Español Français

Français Italiano

Italiano Polski

Polski Česky

Česky USA

USA 中文

中文