E2R Formülasyon

Are you overwhelmed by the number of production processes?

What about having them all under control?

Choose the best module for your company.

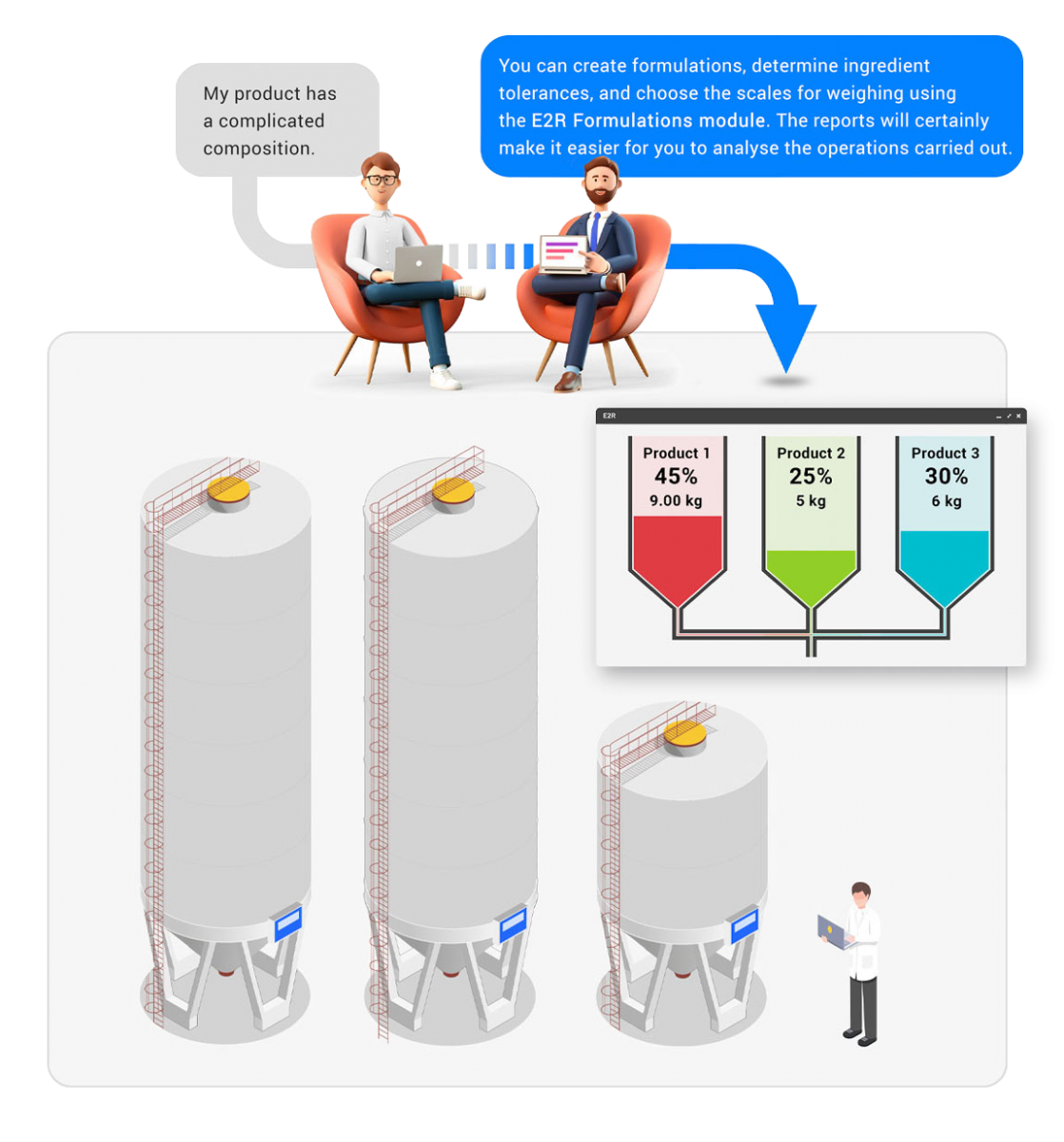

With the E2R Formulations module, you can:

- create formulations;

- manage formulations;

- create simple reports of the carried out formulations;

- support E2R System databases such as “Products” and “Operators”;

- exchange data with external programs via the Data Synchronisation Module;

- change the application’s skins.

- preview the carried out measurements,

- carry out formulations based on production orders,

- determine the amount of each formulation ingredient,

- determine the tolerance of the weighed ingredient,

- dose the formulation up to a specified mass,

- integrate with the Data Synchronisation Module,

- carry out production orders,

- define the permission levels for specific operators,

- carry out production orders with batches,

- weigh remains of each batch portion,

- perform multiple weighing procedures of one ingredient,

- weigh each ingredient of the formulation on a different scale or platform,

- enter the batch number after each weighing,

- carry out formulation with the dosing function,

- carry out production orders on several scales,

- repeatedly carry out formulations,

- manage the “Formulations” and “Orders” databases,

- carry out production orders divided into phases,

- hold up formulations and production orders performance,

- operate receipt and label printers,

- label directly from the PUE 5 terminal.

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch English

English Español

Español Français

Français Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Česky

Česky USA

USA 中文

中文