E2R PGC

Are you overwhelmed by the number of production processes?

What about having them all under control?

Choose the best module for your company.

Need more information?

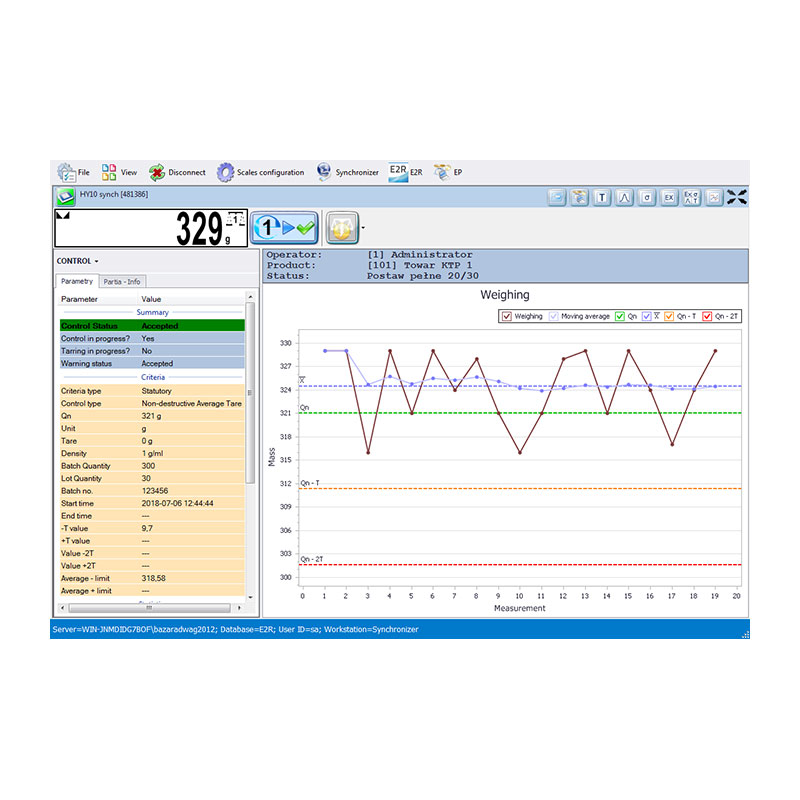

- safely and continuously record measurements and controls at the weighing workstations;

- buffer the weighings and controls on the scales and transmit them to the computer;

- carry out product controls in grams and millilitres;

- carry out destructive and non-destructive controls;

- automate the control process;

- control operator errors;

- support dual-platform scales;

- carry out two controls at one weighing workstation;

- synchronise time of the weighing workstations;

- transfer the “Products”, “Operators” and “Schedules” databases from the computer to the scales;

- schedule a cyclic product control on the selected scales;

- set a reminder to take a measurement in an ongoing control with the possibility of using a signalling option;

- check correctness and determine tare thanks to the average tare module;

- determine the average tare before each control or at the set interval;

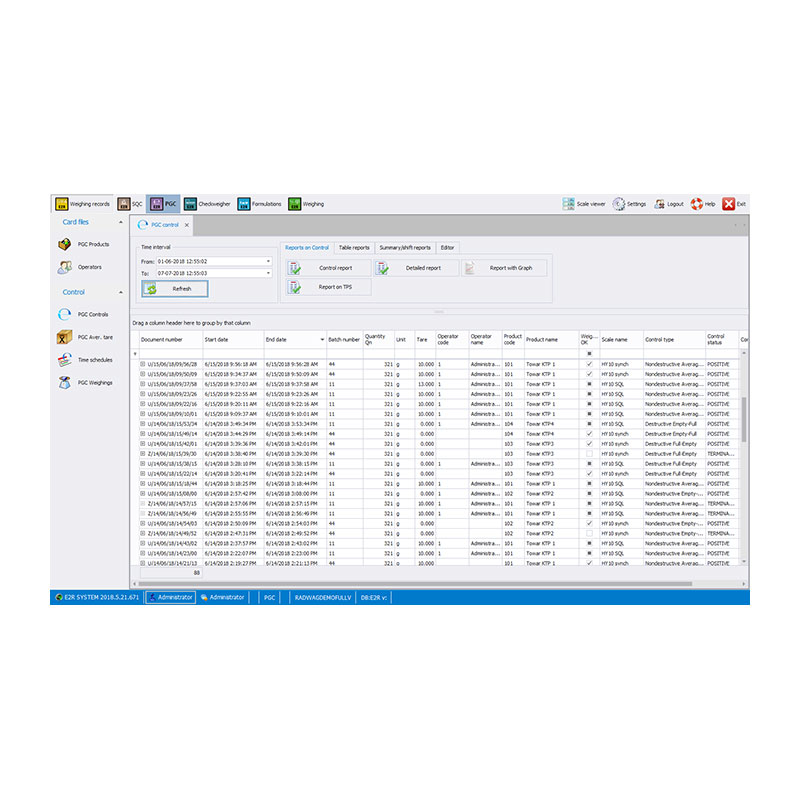

- record weighings and controls taken from the scales into the computer;

- monitor the status of scales and controls in the system;

- disable the measurement recording for tare outside the tolerance range;

- disable the recording of the net mass measurement outside the tolerance range;

- exchange data with external systems;

-

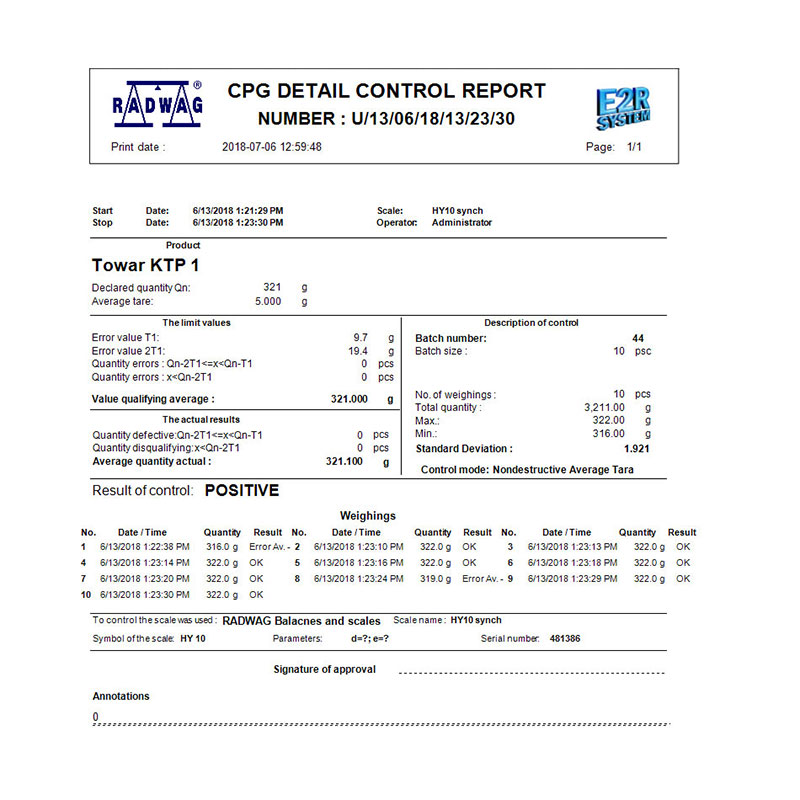

use friendly and flexible reporting mechanisms, such as:

- generating information on measurements and archived controls from a particular time interval,- data browsing using filtering option,- a summary of selected weighing-related information,- reporting of individual weighings,- determining headers of individual weighing reports,- generating weighing statistics reports,- changing the batch quantity in the control to meet the statutory ranges criteria,- changing the batch number in the control,- adding individual comments to the control report.- export control and weighing reports to files: PDF, HTML, MHT, RTF, XLS, XLSX, CSV, TXT and more;

- customize the permission levels for different users of the system;

-

customize the graphical interface, reports and graphs;

- work with external software for stockpiling, billing, accounting, and ERP systems;

- work with RADWAG weighing systems;

- select the language of each of the system components;

- work almost anywhere over Ethernet and Wi-Fi®.

Wi-Fi® is a registered trademark of Wi-Fi Alliance®.

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch English

English Español

Español Français

Français Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Česky

Česky USA

USA 中文

中文