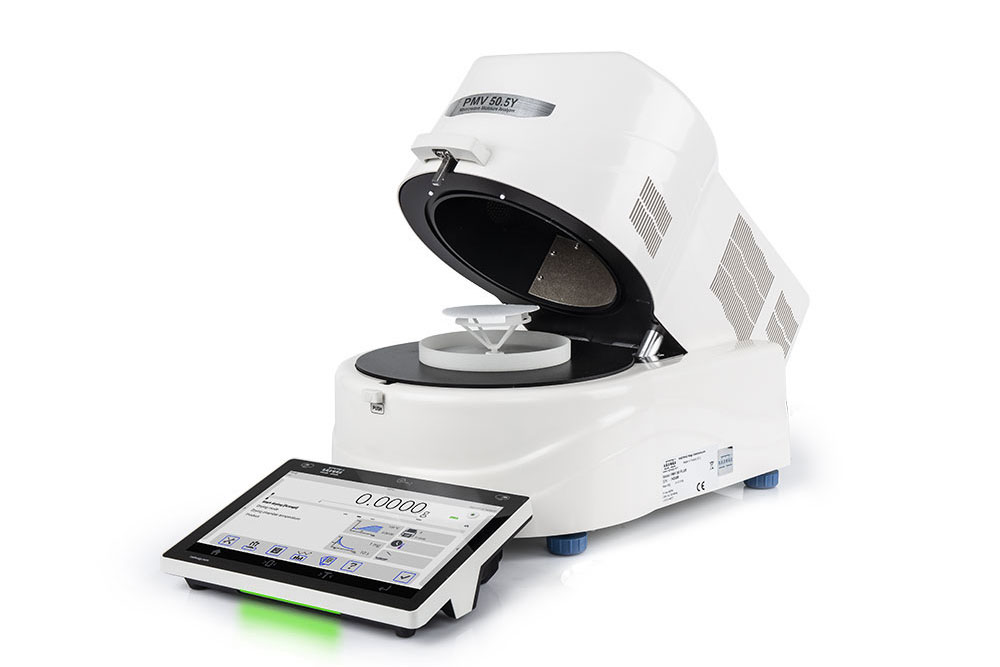

Termobilancia PMV 50.5Y

The PMV 50.5Y

The sample is placed in the drying chamber on a glass fibre filter. At the bottom of the chamber there is one end of the waveguide from where the microwaves are emitted. Upon process start, microwaves are equally distributed on the filter’s surface and dry the sample. The moisture content is determined on the basis of the mass loss obtained during drying.

A respective drying program is selected depending on sample mass and its chemical composition. The average duration of this process depends on the type and mass of used substance, and takes 1 to 10 minutes. In contrast, drying using the traditional halogen moisture analyzer takes 5 to 40 minutes.

The PMV 50.5Y microwave moisture analyzer is equipped with a temperature sensor and enables to monitor device power in order to prevent exceeding the boiling point during the process. A preset microwave power is displayed on the indicator throughout the drying procedure.

The PMV 50.5Y’s main features:

- intended for drying of samples containing significant amount of moisture (up to 100%),

- ultra-short drying time when compared to traditional moisture analyzers and standard drying methods,

- microwave-based solution,

- uniform heating of entire sample’s surface,

- complex database of drying programs,

- finish mode: manual, automatic, time-defined, user-defined,

- advanced reports, time and statistical graphs,

- easy operation due to a touch screen.

For each purchase of the PMV 50.5Y moisture analyzer the customer is supplied with:

- 60 glass fibre filters of ø90 mm,

- a sample of sodium chloride 10% ± 0,5% to determine correctness of the operation at the workstation,

- a service concerning determination of drying parameters for five customer-selected samples carried out by RADWAG employee.

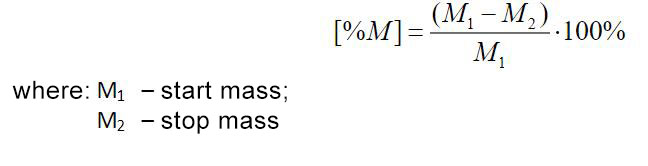

% M – the mass loss in %; displays the mass change recorded during the drying process, expressed as a percentage,

% D – the dry mass obtained during the drying process, expressed as a percentage; the result is the portion of the sample that remains on the weighing pan after the moisture has evaporated,

% R – the ratio of moisture content to dry mass, obtained during the drying process, expressed as a percentage; the result is the portion of the sample that evaporated during the drying process,

g – the sample mass after drying.

* All trademarks and registered trademarks are the property of their respective owners.

Terminal 5Y in Microwave Moisture Analyzer

- 10-inch display,

- Digital Weighing Auditor (DWA),

- uncompromised user verification,

- Ambient Light,

- hotspot,

- RFID*,

- Live Note text notes,

- voice commands for the device,

- measurement history within the Handy Library,

- widgets.

Modbus TCP/IP

Learn about the use and maintenance of stainless steel products:

Stainless Steel in RADWAG products. Standard and special applications

Wi-Fi® is a registered trademark of Wi-Fi Alliance®.

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch English

English Español

Español Français

Français Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文