Balance de précision WLC 6.X7

De nouvelles fonctionnalités

- écran tactile couleur de 7 pouces

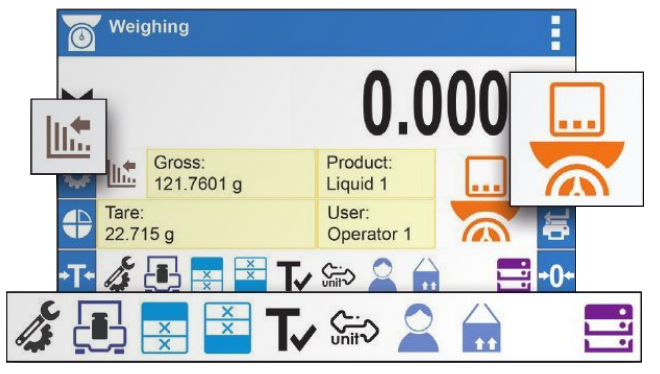

- personnalisation de l’écran via des widgets

- un menu interactif multilingue

- capteurs de fonctionnement sans contact

- conformité aux exigences BPL et BPF

- contrôle dynamique du poids de l’échantillon (bargraph)

- statistiques, recettes, rapports et impressions

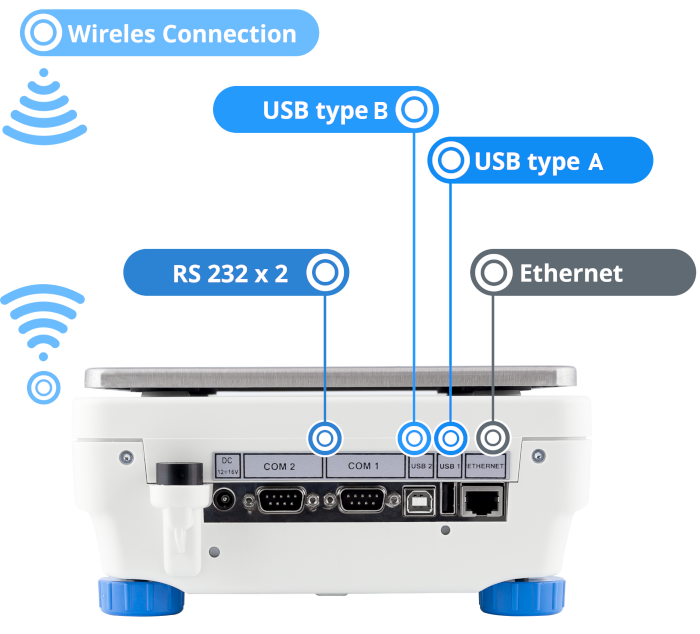

- possibilités de communication illimitées

- mémoire ALIBI avec enregistrement des mesures

- bases de données développées

- confort d’utilisation le plus élevé

- ajustage interne/ externe

Personnalisation via des widgets

Les balances de précision WLC X7 sont équipées de plusieurs interfaces de communication : 2 x RS232, USB-A, USB-B, Ethernet et Wi-Fi®.

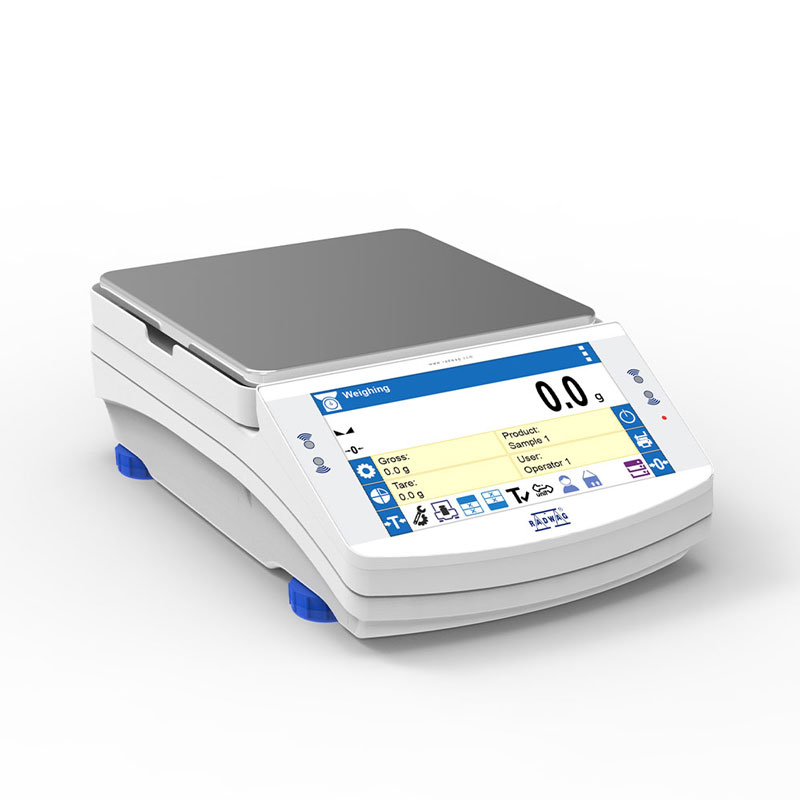

Le boîtier de ces appareils est en plastique et le plateau de pesée est en acier inoxydable.

Base de donnees

- Produits (5 000 marchandises)

- Utilisateurs (100 utilisateurs)

- Emballage (100 colis)

- Clients (1 000 clients)

- Recettes (100 recettes)

- Rapports de recettes (500 rapports)

- Conditions environnementales (10 000 enregistrements)

- Pesée (50 000 enregistrements)

- Alibi (512 000 pesées).

Gestion de données

Mémoire Alibi

Learn about the use and maintenance of stainless steel products:

Acier inoxydable dans les balances RADWAG

Wi-Fi® est une marque déposée de Wi-Fi Alliance®.

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch English

English Español

Español Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文