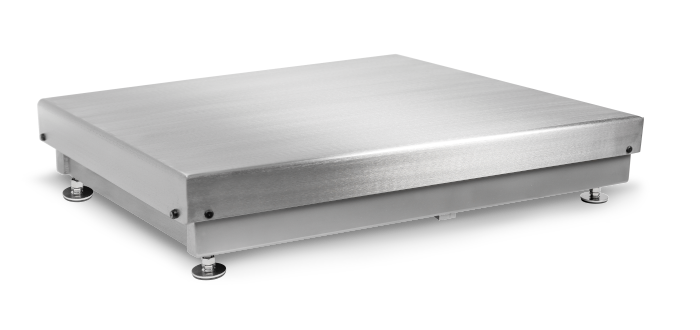

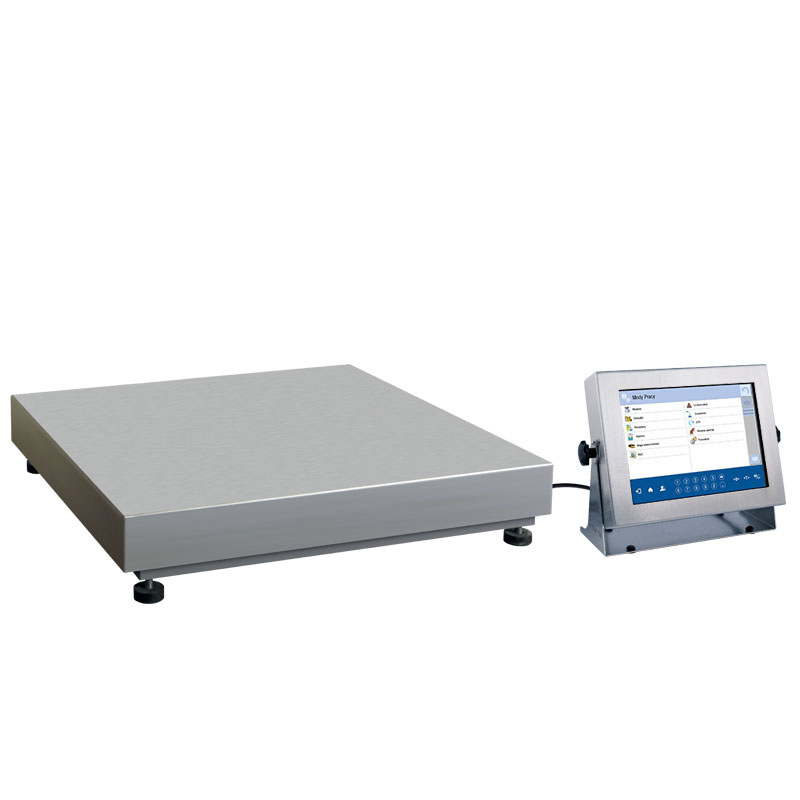

La mayor resistencia

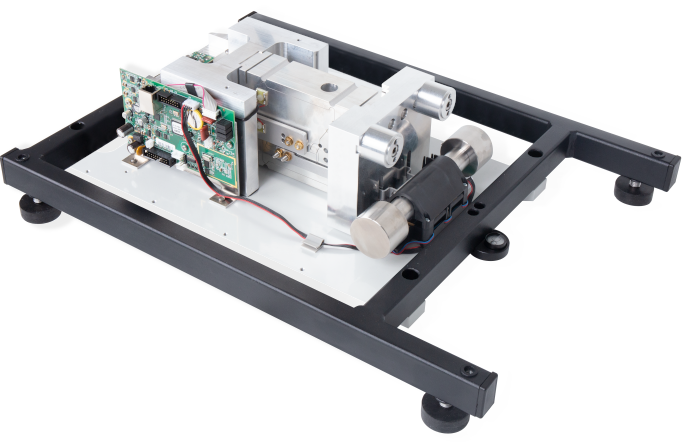

9 ventajas, 1 monobloque

MONO

BLOCK® . El nuevo

MONO

BLOCK® , cada vez más alto, ha permitido la mejor repetibilidad y velocidad en la clase de plataformas de pesaje industriales de alta resolución.Repetibilidad no repetible por otros

Para industrias como la farmacéutica, química, alimentaria y…

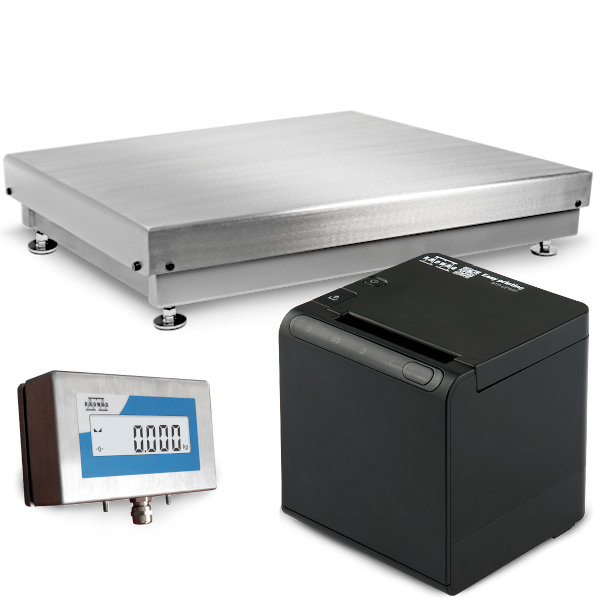

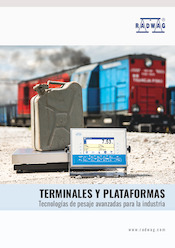

Elige un terminal

- pantalla resistiva de color de 5,7 pulgadas

- un teclado táctil

- carcasa de plástico ABS

- grado de protección IP 43

-

interfaces de comunicación: 2xRS232, 2xUSB-A, Ethernet, 4 IN/ 4 OUT,

Wi-Fi®® - módulos adicionales opcionales: módulo convertidor A/D adicional DP6.

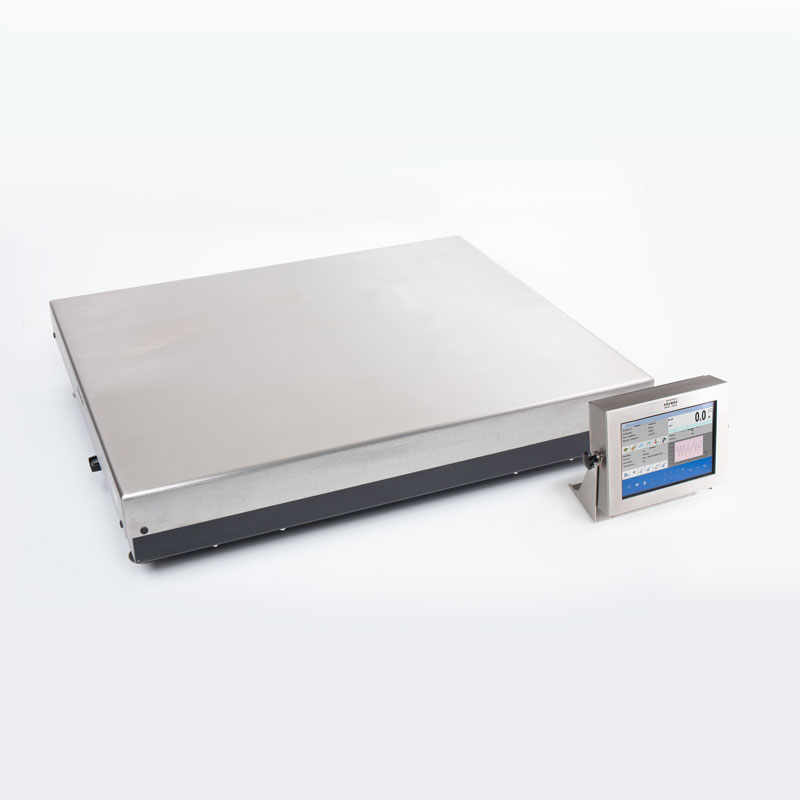

- pantalla gráfica de color de 10,1 pulgadas

- un teclado táctil

- carcasa de acero inoxidable

- grado de protección IP 68/69

- interfaces de comunicación: 2xRS232, 2xUSB-A, Ethernet, 4 IN/ 4 OUT

- módulos adicionales opcionales: Wi-Fi®®, RS485, Profibus, Profinet, módulo de salidas analógicas, 12 IN/ 12 OUT.

El poder del acero

¿Necesitas una memoria ALIBI?

Usa el potencial

No sólo pesaje

Learn about the use and maintenance of stainless steel products:

Stainless Steel in RADWAG products. Standard and special applications

Wi-Fi® es una marca registrada de Wi-Fi Alliance®.

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Deutsch

Deutsch English

English Français

Français Italiano

Italiano Polski

Polski Türkiye

Türkiye Česky

Česky Português (Brasil)

Português (Brasil) USA

USA 中文

中文