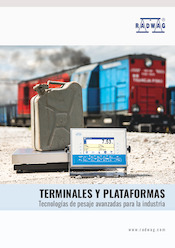

Terminal de pesaje PUE C315

The PUE C315 terminal is intended for fast and precise presentation of mass measurement result. Taring available for the whole weighing range allows to swiftly and precisely determine net mass of weighed loads. An ABS plastic housing ensures durability and lightness of the construction.

Uncomplicated Operation and Clear Presentation of Indications

A clear 6-digit LCD display with backlight and pictograms provides clearly visible measurement result. Easy operation enables fast and reliable measurements to be carried out even by an inexperienced operator.

Mobility due to an Internal Battery

In addition to power supply from the mains, PUE C315 terminal is equipped with internal battery that enables several hours long mobile operation.

Versatility of Use

Various possibilities of fastening of the PUE C315 terminal to the weighing platform enable selecting appropriate solution for different places of operation. The terminal can be mounted next to the platform, on a post or using cable.

ALIBI Memory

Internal ALIBI memory guarantees safety and automatic record of measurements copies, it also offers possibility to preview, copy and archive data.

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch English

English Français

Français Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文