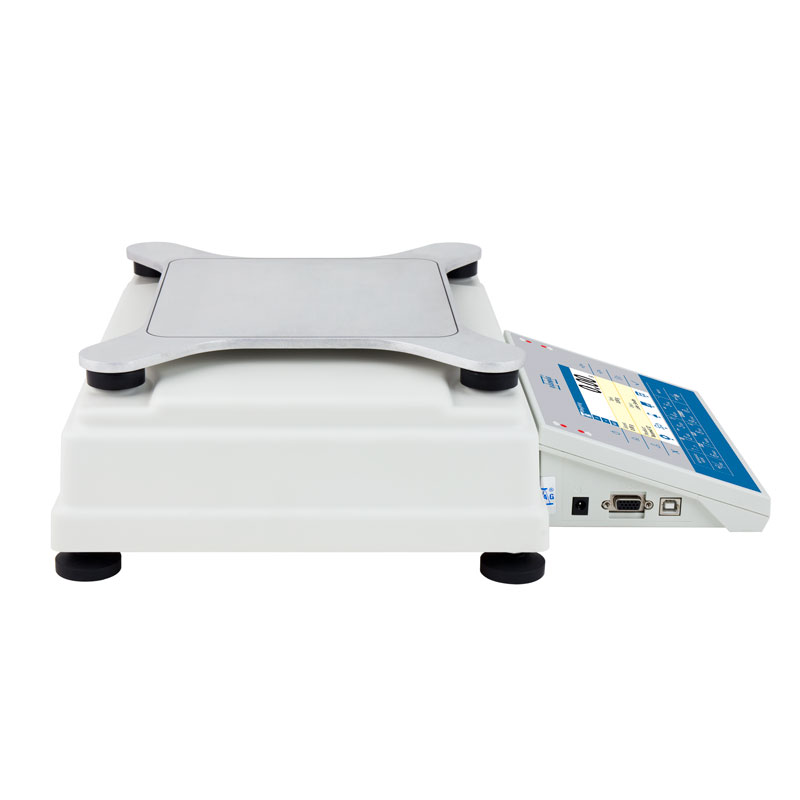

Balanza de precisión C32.15.PM

Precisión de laboratorio en condiciones industriales

- Posibilidad de pesar cargas de hasta 120 kg en un platillo grande con alta precisión y buena repetibilidad,

- mínimo error de excentricidad en todo el rango,

- medición rápida y estable (alcanzable en 1 segundo),

- estabilidad de los parámetros en el tiempo y en el transporte,

- dimensiones del platillo de pesaje adaptadas a la precisión de la balanza

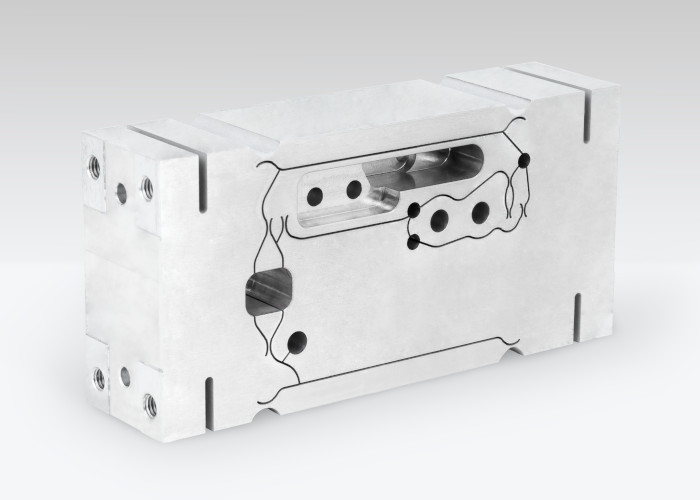

MONO

BLOCK® .

Las balanzas PM también son:

- construcción sólida basada en un monobloque más grande y alto,

- sistema de protección de sobrecarga de 4 puntos incorporado,

- grado de protección IP 43,

- calibración interna,

- Pantalla de color 5",

- fácil puesta en marcha, manejo intuitivo y ergonomía de trabajo.

Interfaces de comunicación

Aprenda que en su petición especial el PUE C32 puede ser equipado con el módulo de comunicación sin hilos que permite que el terminal conecte con redes sin hilos.

Learn about the use and maintenance of stainless steel products:

Stainless Steel in RADWAG products. Standard and special applications

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch English

English Français

Français Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文