5Y.10.PM Precision Balance

- The ability to weigh loads up to 120 kg on a large weighing pan with high accuracy and good repeatability,

- minimum eccentricity error over the entire range,

- quick and stable measurement (achievable within 1 second),

- parameter stability over time and during transport,

- robust design based on a larger and taller ,

- built-in 4-point overload protection system,

- weighing pan dimensions adapted to the accuracy of the balance,

- internal adjustment,

MONO

BLOCK® technology. The change in the design of the

MONO

BLOCK® has made it possible to work with a readability of 0.01 g at a maximum capacity of 20 kg and 0.2 g at a maximum capacity of 120 kg, with a repeatability of 0.01 g, and resistance to changes in ambient conditions.

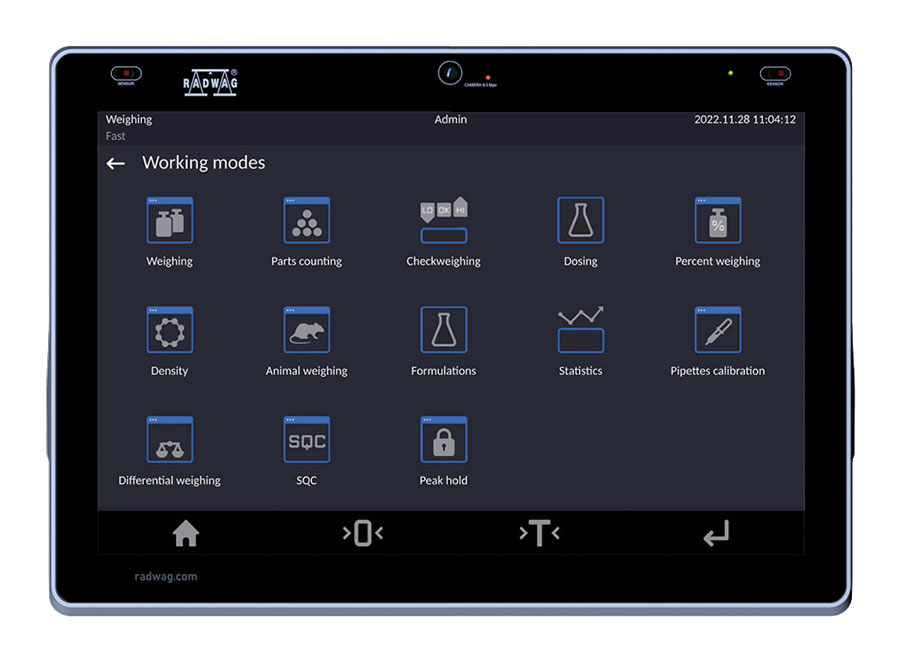

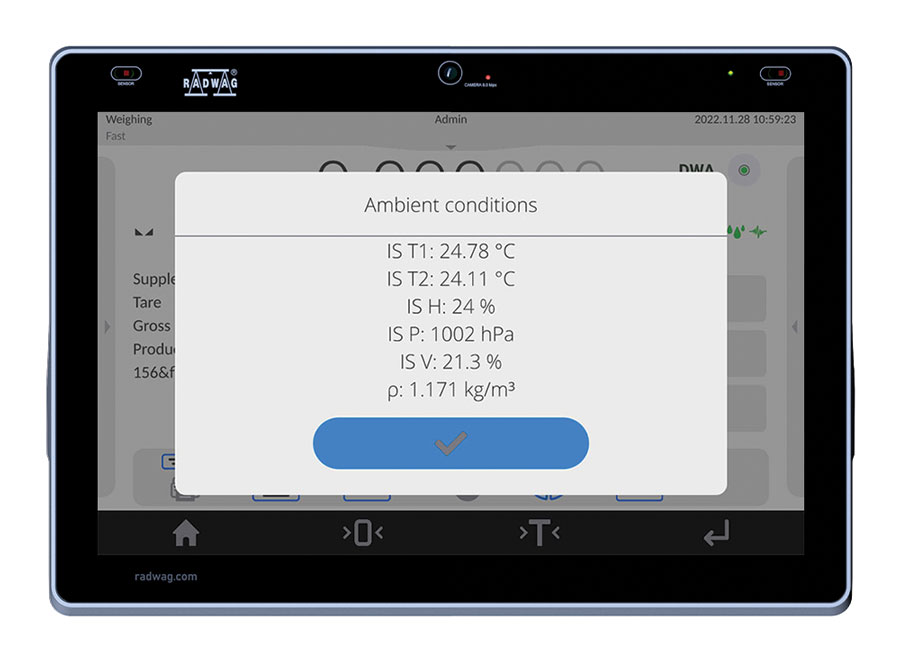

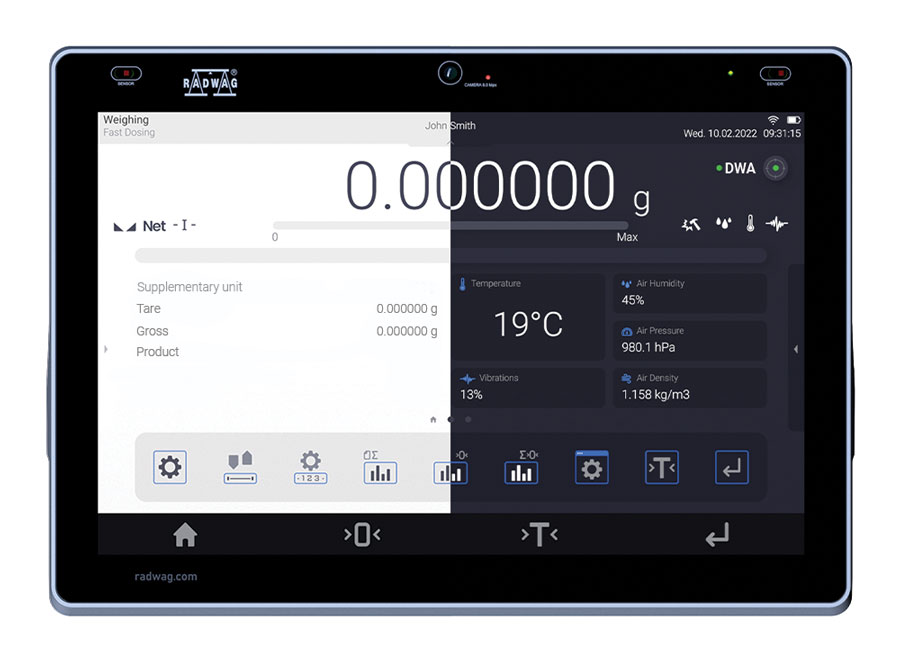

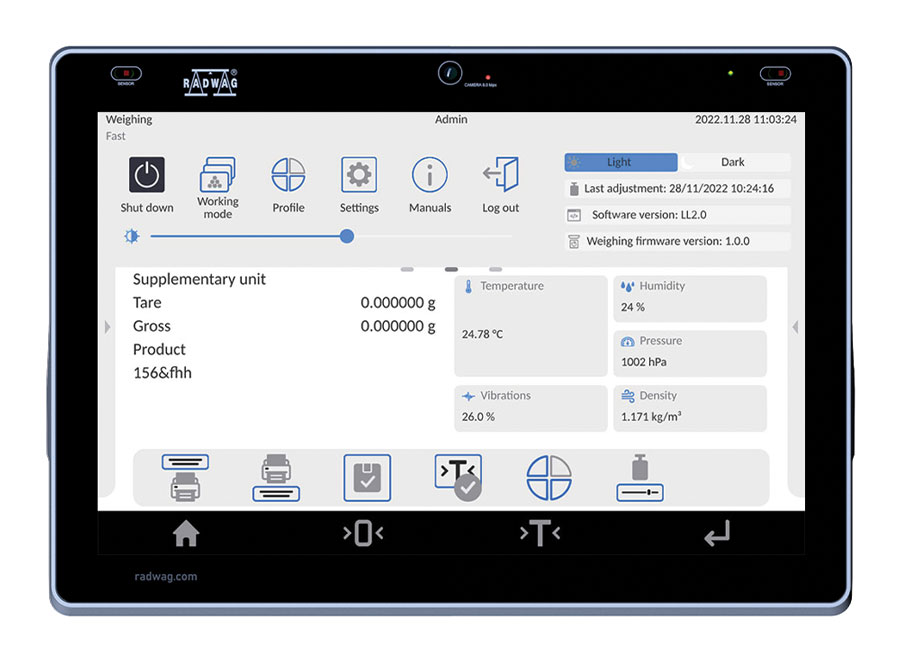

5Y.PM balances also include:

- 10-inch touch screen,

- easy start-up, intuitive operation, and ergonomics,

- compliance with 21 CFR Part 11,

- Digital Weighing Auditor,

- multi-step user verification,

- Ambient Light alerts,

- Hotspot,

- RFID,

- Live Note text notes,

- handy measurement history within the Handy Library,

- widgets.

Application

21 CFR Part 11

Additional fee

Additional fee

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文