Bilancia di precisione C32.25.PM

Precisione da laboratorio in condizioni industriali

- Capacità di pesare carichi fino a 120 kg su un piatto di grandi dimensioni, con elevata precisione e buona ripetibilità,

- errore di eccentricità minimo sull'intera gamma,

- misurazione rapida e stabile (ottenibile entro 1 secondo),

- stabilità dei parametri nel tempo e durante il trasporto,

- dimensione del piatto adattata all'accuratezza della bilancia

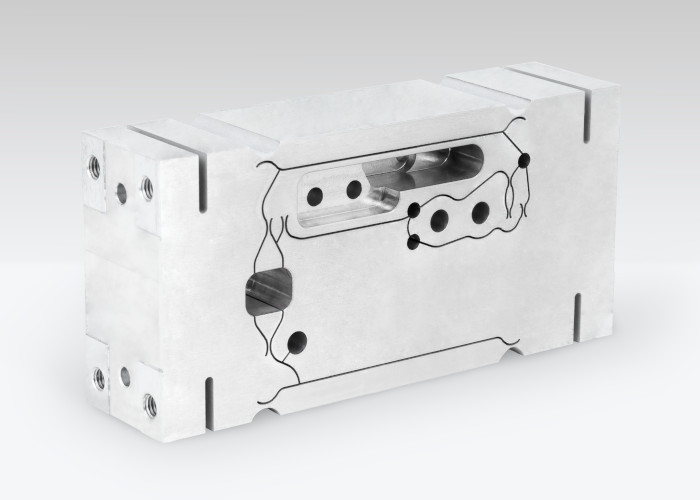

MONO

BLOCK® migliorata.

Le bilance PM sono anche:

- design robusto basato su un monoblocco più grande e più alto,

- sistema di protezione da sovraccarico a 4 punti incorporato,

- livello di protezione IP 43,

- calibrazione interna,

- display a colori,

- facile messa in servizio, funzionamento intuitivo ed ergonomia.

Alimentazione a batteria opzionale

Interfacce di comunicazione

La connettività del terminale alle reti wireless è garantita dal modulo Wireless Connection integrato di serie.

Sistema THBR 2.0

Learn about the use and maintenance of stainless steel products:

Stainless Steel in RADWAG products. Standard and special applications

Additional fee

Additional fee

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch English

English Español

Español Français

Français Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文