Balance de précision 5Y.10.PM

- Possibilité de peser des charges jusqu’à 120 kg sur un grand plateau avec une grande précision et une bonne répétabilité,

- erreur d’excentricité minimale dans toute la gamme,

- mesure rapide et stable (réalisable en 1 seconde),

- stabilité des paramètres dans le temps et dans le transport,

- construction solide basée sur un monobloc plus grand et plus haut,

- système intégré de protection contre les surcharges à 4 points,

- dimensions du plateau de pesée ajustées à la précision de la balance,

- étalonnage interne

MONO

BLOCK® . Le changement de la structure monobloc a permis de travailler avec une précision de 0,01 g avec une capacité de charge de 20 kg et 0,2 g avec une capacité de charge de 120 kg, une répétabilité à partir de 0,01 g et une résistance aux changements de conditions environnementales.

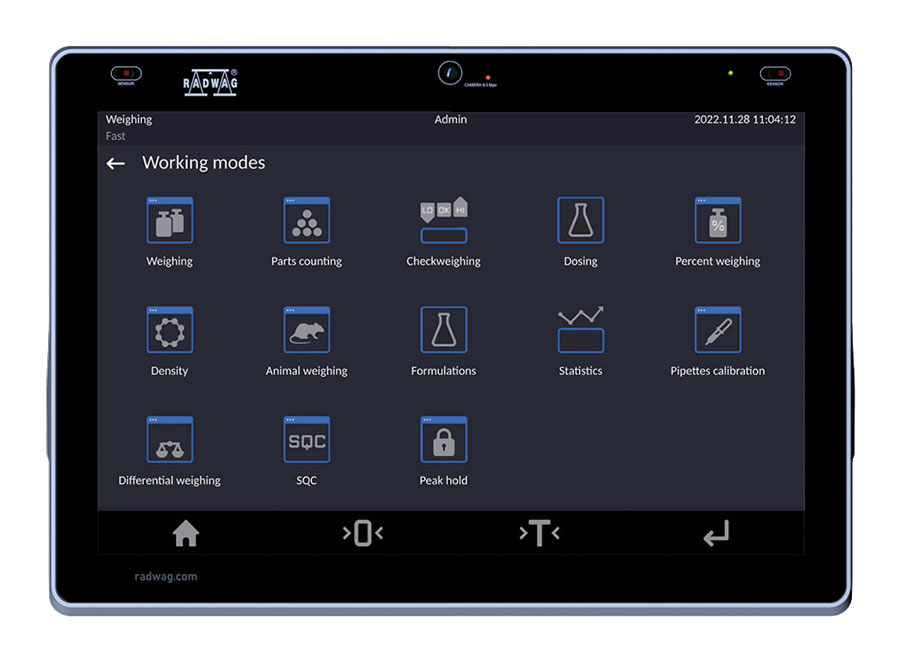

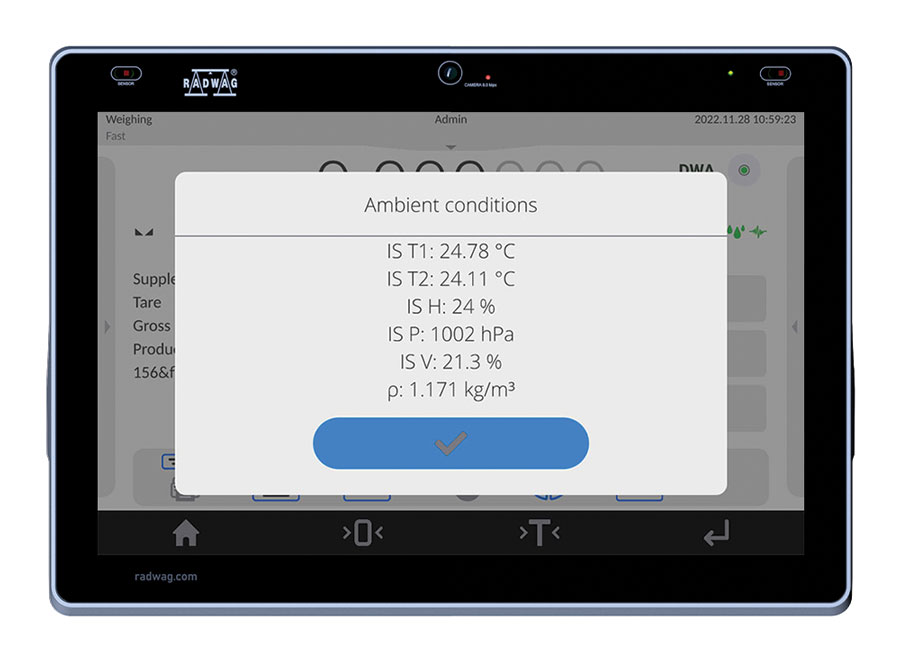

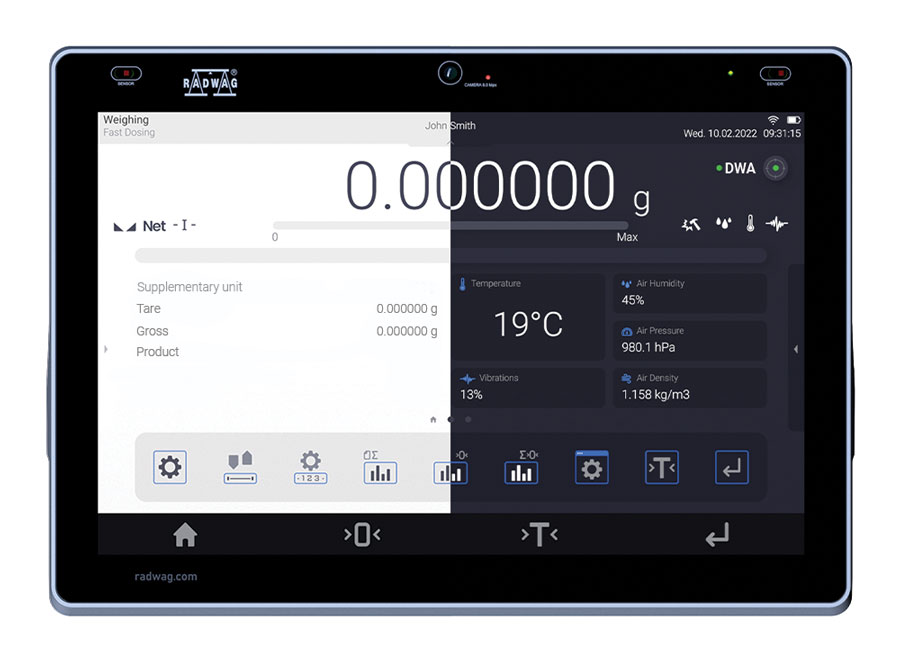

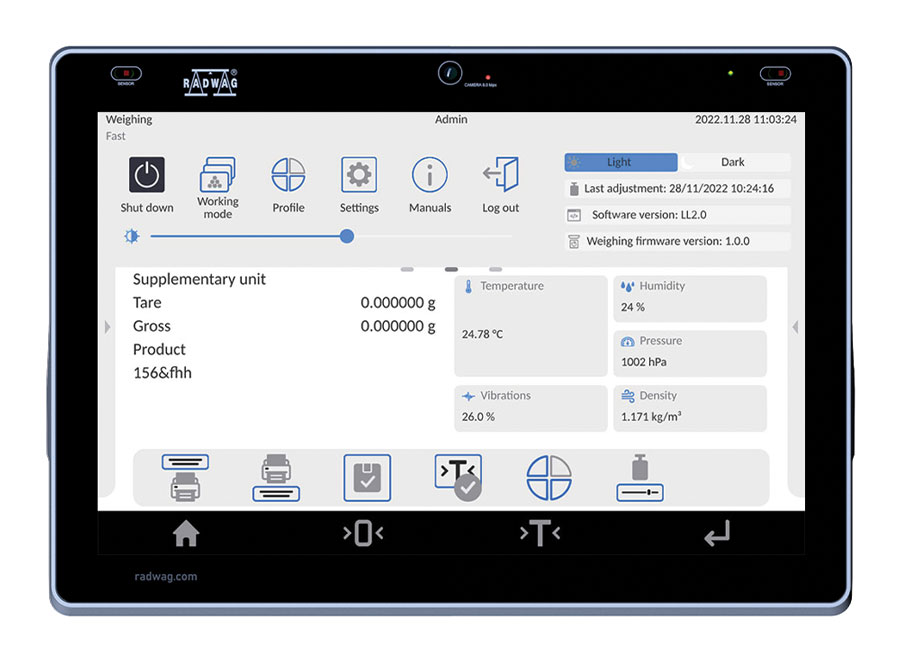

Les balances 5Y.PM comprennent également :

- écran tactile 10 pouces,

- mise en service facile, utilisation intuitive et ergonomie de travail,

- la conformité au 21 CFR Part 11,

- audit numérique de pesée DWA® (Digital Weighing Auditor),

- méthode de vérification de l’utilisateur en plusieurs étapes,

- Alertes lumineuses d’ambiance Ambient Light,

- Hotspot,

- RFID,

- Texte Live Note,

- historique de référence des mesures dans la Handy Library,

- widgets.

Application

21 CFR Part 11

Additional fee

Additional fee

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch English

English Español

Español Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文