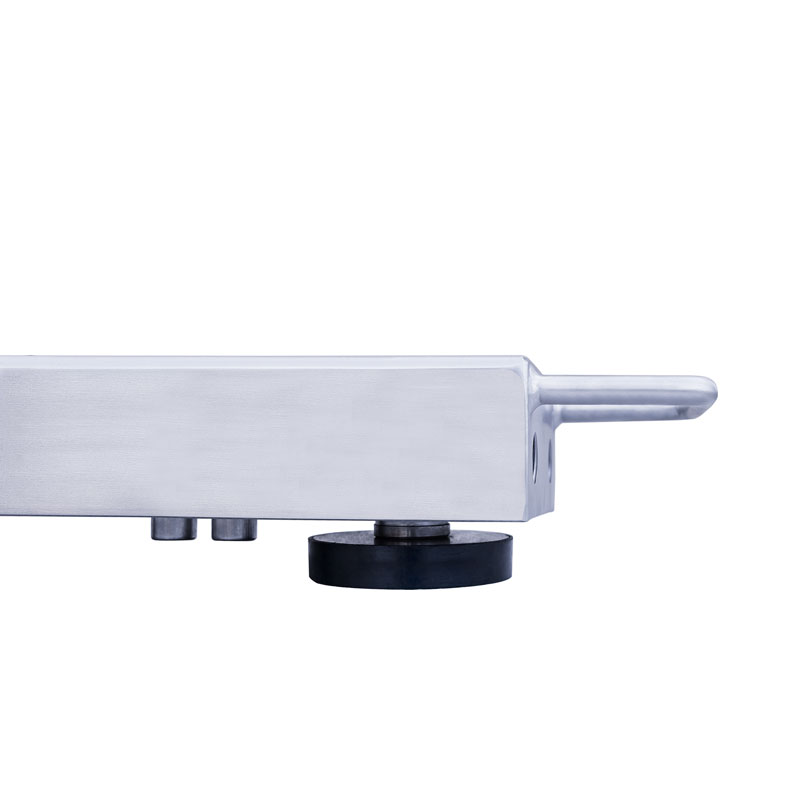

Beam scales H315/4P2/H series is manufactured in stainless steel version. Optionally, the number of beams in a scale can be increased to 4. Beam scales features handles for easy transporting the scales to its place of use.

The scales comes standard with an indicator PUE H315 in stainless steel housing, featuring backlit LCD display and function buttons. The indicator is installed on a long cable.

The scale is powered from mains 230V AC, RS 232 interface comes standard.

Scales is available in dual range version on surcharge.

Learn about the use and maintenance of stainless steel products:

Stainless Steel in RADWAG products. Standard and special applications

Check the price in our store

radwaguk.com

Buying from the producer is all about the pros

You always get the latest version of the device and software. We are constantly improving our products.

Technical support from the product developers. Who better to know the answers to your questions? Like our Facebook – profile – stay in touch with us.

A solidly packaged shipment travels only one way – the one to you.

In our permanent offer you will find accessories for our balances and scales, such as cables, weighing pans and power supplies, as well as all spare parts. And we carry out legalization and periodic inspections in our laboratory.

You buy a product developed and manufactured in Europe – you get a device with a certain standard of compliance.

Extra payment

Extra payment

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano Polski

Polski Türkiye

Türkiye Česky

Česky Português (Brasil)

Português (Brasil) USA

USA 中文

中文