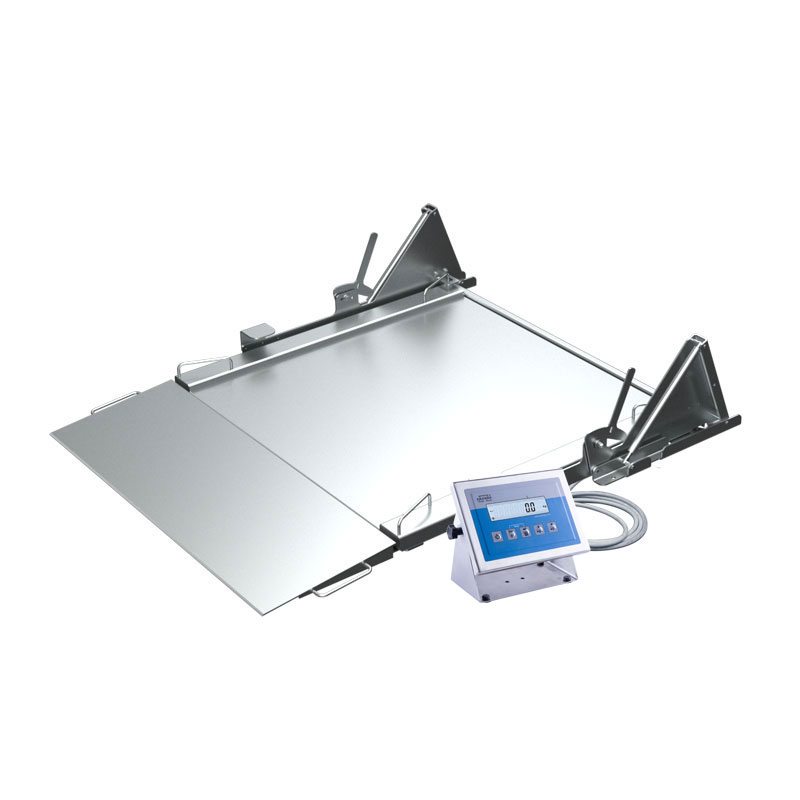

The scale is equipped with LD4N system allowing lifting the platform up, useful for maintenance purposes. The mechanism enables safe platform lifting and does not require physical exertion or additional equipment. Upon platform lowering, the scale is ready to carry out measurement. There is no need for recalibration.

The scale is made of OH18N9 stainless steel and is equipped with PUE H315 indicator. On a customer request the scale can be made of steel of increased anti-corrosion resistance.

The length of the cable for connecting the indicator to the platform - 3m.

Ramp scale with LD4N system is equipped with only one ramp.

Dual range weighing instrument for an additional charge.

Learn about the use and maintenance of stainless steel products:

Stainless Steel in RADWAG products. Standard and special applications

Additional fee

Additional fee

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文