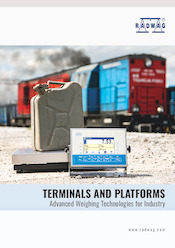

Beam scales C315.4P2 series is stable and proved four load cells weighing solution with more versatile application than standard pallet scales. The adjustable distance between the beams (up to 5 meters) enables fitting the C315.4P2 scales to different loads (cases, long bars, heavy sections). The load to be weighed can be placed on the beams by a standard fork-lift truck.

Beam scales C315.4P2 series is manufactured in mild steel powder coated version. Optionally, the number of beams in a scale can be increased to 4. Beam scales features handles for easy transporting the scales to its place of use.

The scales comes standard with an indicator PUE C315 series featuring backlit LCD display and function buttons. The indicator is installed on a long cable.

The scale is powered from mains 230V AC, RS 232 interface comes standard.

Scales is available in dual range version on surcharge.

Beam scales C315.4P2 series is manufactured in mild steel powder coated version. Optionally, the number of beams in a scale can be increased to 4. Beam scales features handles for easy transporting the scales to its place of use.

The scales comes standard with an indicator PUE C315 series featuring backlit LCD display and function buttons. The indicator is installed on a long cable.

The scale is powered from mains 230V AC, RS 232 interface comes standard.

Scales is available in dual range version on surcharge.

Stainless Steel in RADWAG products

Learn about the use and maintenance of stainless steel products:

Stainless Steel in RADWAG products. Standard and special applications

Learn about the use and maintenance of stainless steel products:

Stainless Steel in RADWAG products. Standard and special applications

Additional fee

Additional fee

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文