Wägeterminal PUE HY10

GEHÄUSE

- Das Gehäuse und der Sockel des Terminals sind beide aus Edelstahl gefertigt. Alle HY10-Steckverbinder werden durch Stopfbuchsen geführt, die zusammen mit dem wasser- und staubdichten Gehäuse eine hohe IP-Einstufung, d.h. IP68/69, garantieren.

- Das 2-Punkt-Befestigungssystem für den Terminal-Sockel ermöglicht es Ihnen, Ihr LCD frei zu neigen. Die Möglichkeit der Neigungswinkelverstellung verbessert die Ergonomie der Bedienung und optimiert die Sichtbarkeit der Anzeige.

- Das große, hintergrundbeleuchtete 10,1-Zoll-Farbdisplay garantiert auch bei schlechten Lichtverhältnissen eine gute Lesbarkeit der Informationen. Die Anzeige kann aus einer beträchtlichen Entfernung abgelesen werden, was Ihre Mobilität erhöht.

- Die hohe Auflösung (1024x600) bedeutet eine hohe Lesbarkeit der Anzeige und sorgt für schärfere Ziffern, Symbole usw. Jetzt leiden Sie nicht mehr unter Augenbelastung. Je höher die Auflösung, desto weniger wird Ihre Sehkraft beeinträchtigt, ganz zu schweigen von einem höheren Komfort.

- Der Touchscreen steht für eine einfache Bedienung, vertrauen Sie einfach Ihrer Intuition und beginnen Sie mit der Bedienung des Gerätes. Jetzt ist Zubehör wie Maus oder Tastatur überflüssig. Zusätzliche numerische Tasten und Softbuttons sorgen für maximale Funktionalität.

Die Parameter von PUE HY10 können entweder ferngesteuert oder über das Terminal eingestellt werden. Die Verwendung der 'Parameter-Editor 2.0'-Software ermöglicht eine wiederholbare Parametereinstellung.

Sobald Sie alle Parameter für ein bestimmtes Terminal eingestellt haben, speichern Sie sie in einer Datei, um sie auf Terminals zu kopieren, die an zwillingsähnlichen Arbeitsstationen arbeiten.

Die Einrichtung des Terminals kann entweder mit einem USB-Flash-Laufwerk oder über das Netzwerk erfolgen. Der 'Parameter-Editor 2.0' bietet die Option eines Remote-Desktops. Mit dieser Lösung können wir die Einrichtung Ihres Terminals auch dann vornehmen, wenn Ihr Unternehmen kilometerweit vom Dienst entfernt ist.

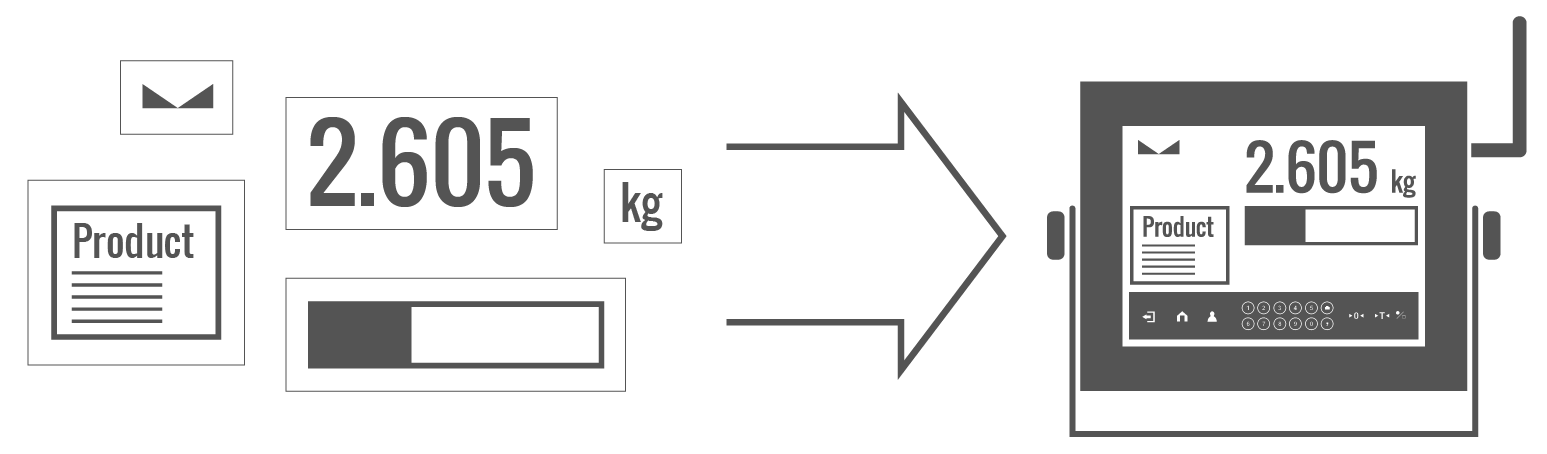

Das PUE HY10-Terminal bietet eine Anpassung des Bildschirmlayouts. Sie können nur die Komponenten anzeigen, die Sie für Ihre Arbeit unentbehrlich finden.

Sie können nicht nur entscheiden, was Sie zu Ihrem Bildschirm hinzufügen möchten, sondern auch die Größe einer bestimmten Komponente bestimmen. Das selbst entworfene Bildschirmlayout erleichtert Ihnen die Arbeit, und der Wiegevorgang ist nun nicht mehr zeitaufwendig.

- die Erstellung einer Etiketten-Datenbank in einem Terminal;

- die Zuordnung entweder eines kundenspezifischen Etiketts zu einem bestimmten Produkt oder eines gemeinsamen Etiketts zu einer Gruppe von Produkten;

- Drucken von C-Etiketten (Palette) und CC-Etiketten (Behälter) mit Gesamtgewicht und -menge;

-

automatisch ausgelöster Ausdruck von C-Etiketten.

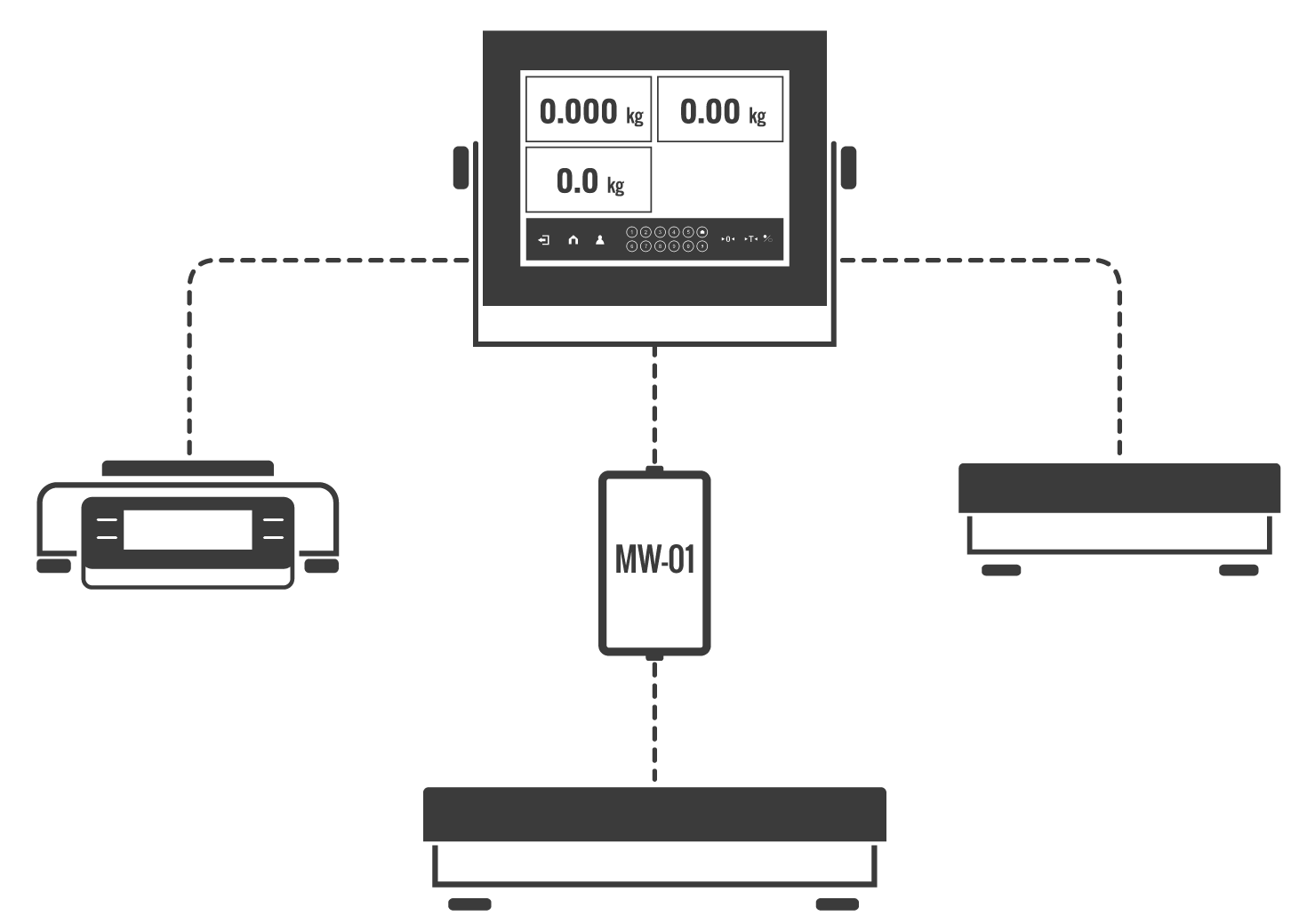

Standardausführung: Unterstützung einer Wägezellenplattform

Optionales Design: Unterstützung von maximal 4 zusätzlichen Plattformen (2 internes Module plus 2 externe Module)

Erfahren Sie mehr über die Verwendung und Pflege von Edelstahlprodukten:

Rostfreier Stahl in RADWAG-Produkten. Standard- und Spezialanwendungen

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) English

English Español

Español Français

Français Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文