Set of holders for microscale glassware by RADWAG

XA 5Y Unpacking and Installation (Tutorial)

RTP - The First Receipt Printer of RADWAG Production!

Statistical Quality Control

What Interfaces do RADWAG Balances Have? Wi-Fi®, USB, Ethernet, HDMI and More!

Discover Hotspot in RADWAG Balances

New Design of RADWAG Balances – Easy Cleaning

Precision and Working Comfort – Operating RADWAG Balances in Every Glove!

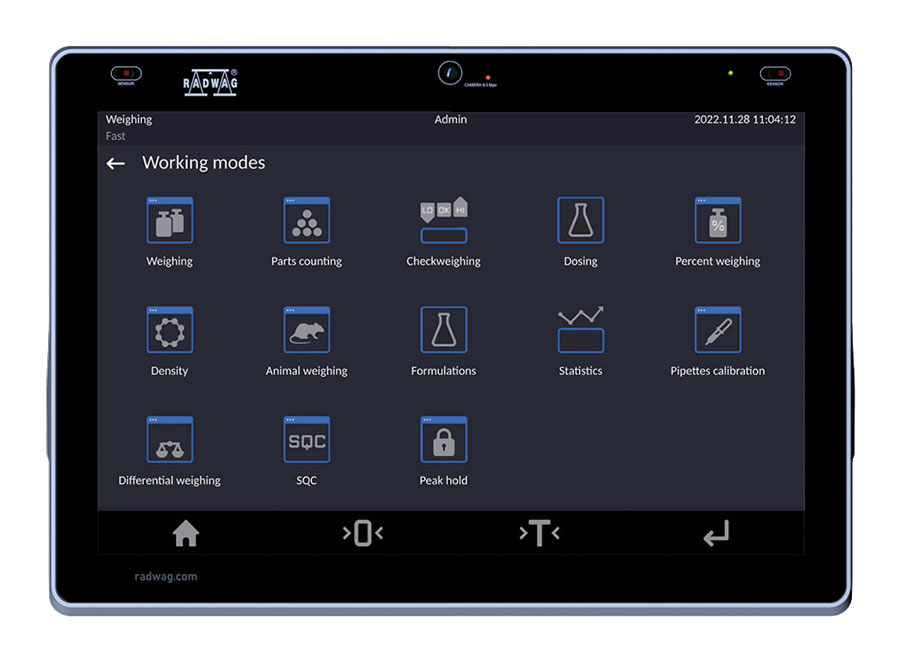

5Y Functions: Animal Weighing

5Y Balance and Barcode Scanner – Easy Connection

New Menu Language in 5Y Series Balances: Japanese

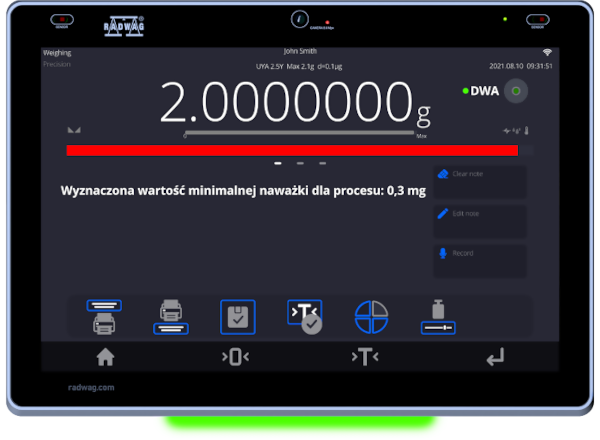

5Y Functions: Checkweighing

5Y Functions: Formulations

5Y Functions: Parts counting

5Y Functions: Proximity Sensors – Touch-Free Control (Tutorial)

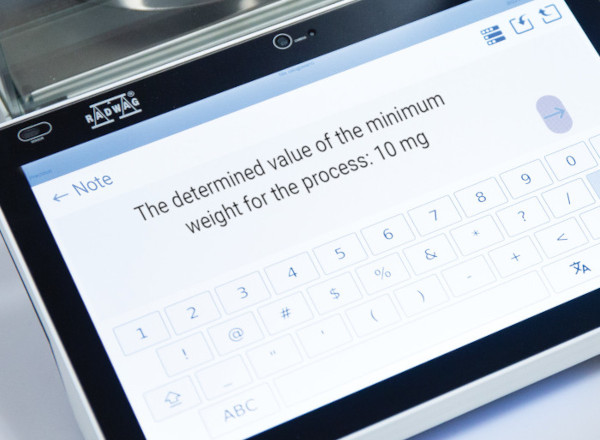

5Y Functions: GLP Procedures – Objective Documentation of Measurements (Tutorial)

Weighing Printout Design in Analytical and Precision Balances (Tutorial)

Stampa facile con l’RTP-UEW80 con Wi-Fi®®

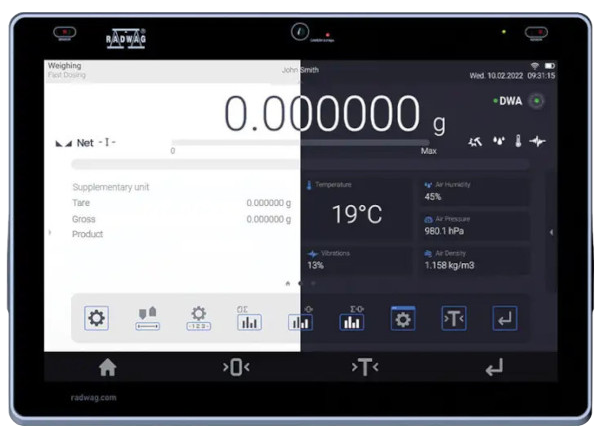

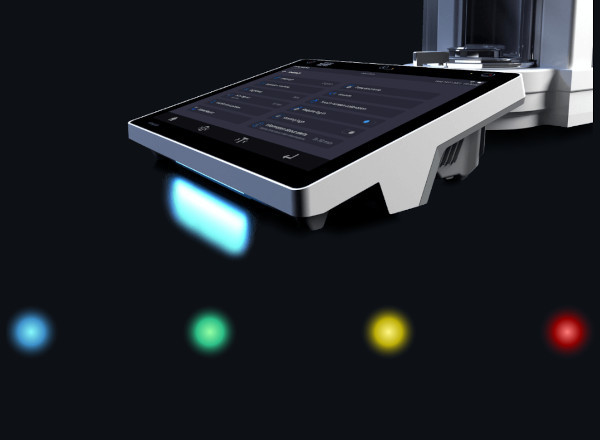

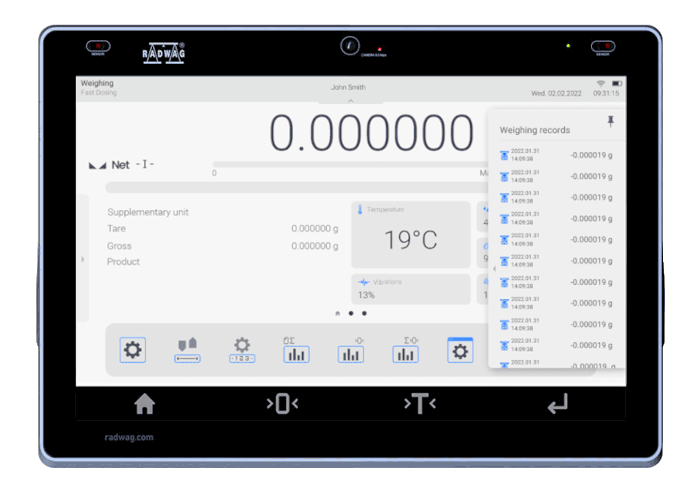

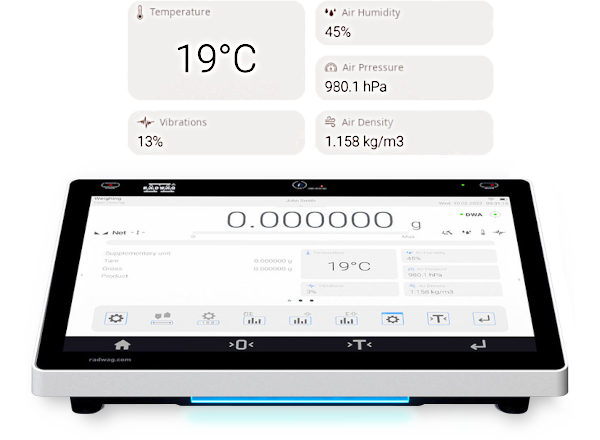

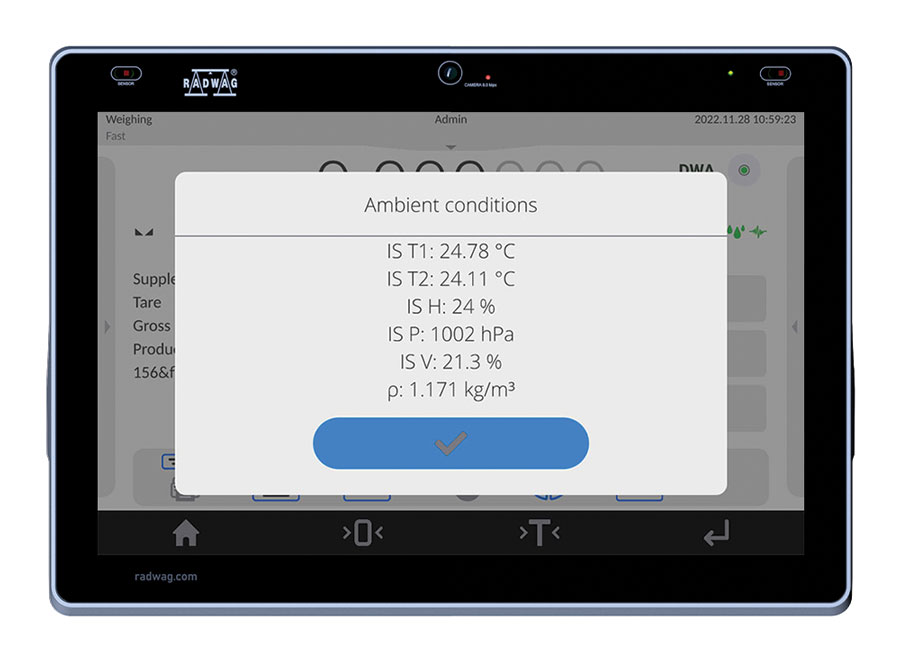

ELLIPSIS – New Balance by RADWAG

ELLIPSIS – Cutting Edge, Innovative, New

Talk to it. Voice Commands in New ELLIPSIS Balance by RADWAG

310 ELLIPSIS – Scan or Tap to Log In

Remote VPN Support on ELLIPSIS Balances

ELLIPSIS – Unlimited Connections

Connecting RADWAG RTP-UEW80 Printer via Wi-Fi® (Tutorial)

Complete Solutions for Mass Measurement in Pharma Industry

New AS and PS 5Y Balances – Autotest (Tutorial)

Additional fee

Additional fee

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch English

English Español

Español Français

Français Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文