Balance de précision WTC

Détermination de masse rapide et précise aussi bien en laboratoire qu’en usine de production. L’électronique et l’écran à économie d’énergie combinés à une batterie interne forment le duo parfait qui vous permettra de travailler sans accès au secteur.

Précision non seulement dans le nom

Lorsque nous avons conçu cette balance, nous avons prêté attention aux moindres détails : ceux que vous ne pouvez pas voir, cachés dans le boîtier solide, et ceux que vous pouvez toucher. Cette balance est le résultat de la combinaison de notre expérience et d’une véritable précision.

Le pouvoir de l’acier

L’utilisation d’acier inoxydable pour fabriquer le plateau de pesée garantit une longue durée de vie de la balance. Elle ne craint pas le contact avec des objets mouillés ni les éclaboussures accidentelles.

Le temps compte

La balance est équipée d’une horloge en temps réel qui garantit une mesure précise du temps indépendamment d’une alimentation externe.

Il est avec nous depuis des années et le restera encore longtemps

L’écran LCD existe depuis longtemps. Durant cette période, il a prouvé sa fiabilité. Il garantit la lisibilité du résultat sous de nombreux angles et est économe en énergie.

Force intérieure

Pas d’accès au secteur ? Panne électrique ? N’a pas d’importance. La batterie interne combinée à l’écran d’économie d’énergie et à l’électronique permettent de nombreuses heures de fonctionnement sans alimentation secteur.

Autre chose?

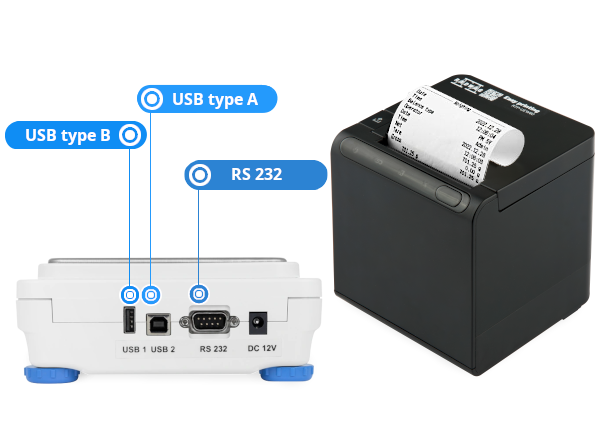

Beaucoup de ! Imprimante, ordinateur, clé USB, écran supplémentaire, la balance WTC peut fonctionner avec eux grâce aux interfaces de communication. De plus, il existe une horloge en temps réel et une mémoire de pesée ALIBI. Vous trouverez tous les accessoires dans notre offre permanente. Et si vous avez des questions sur la compatibilité, nos experts vous aideront.

Avez-vous besoin d’un ALIBI ?

Voilà. La mémoire ALIBI est comme la boîte noire d’une balance. Elle enregistre toutes les mesures effectuées sur le dispositif. La mémoire ALIBI ne peut pas être modifiée ou supprimée.

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Deutsch

Deutsch English

English Español

Español Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky Português (Brasil)

Português (Brasil) USA

USA 中文

中文