Balanza de precisión WLC 2.X7

Nuevas posibilidades

- pantalla táctil a color de 7 pulgadas

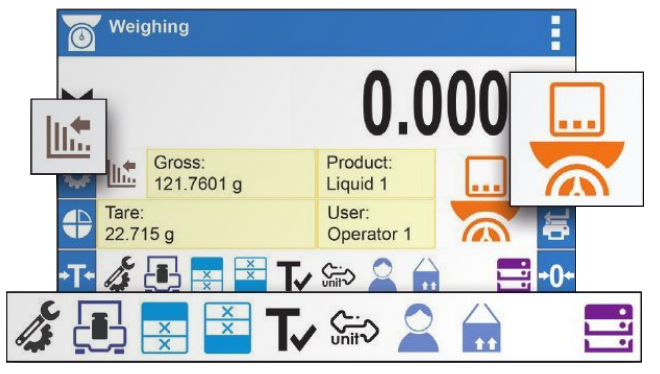

- personalización de la pantalla mediante widgets

- menús interactivos multilingües

- sensores de funcionamiento sin contacto

- cumplimiento de los requisitos de GLP y GMP

- control dinámico de la masa de la muestra (barra grafica)

- estadísticas, recetas, informes e impresiones

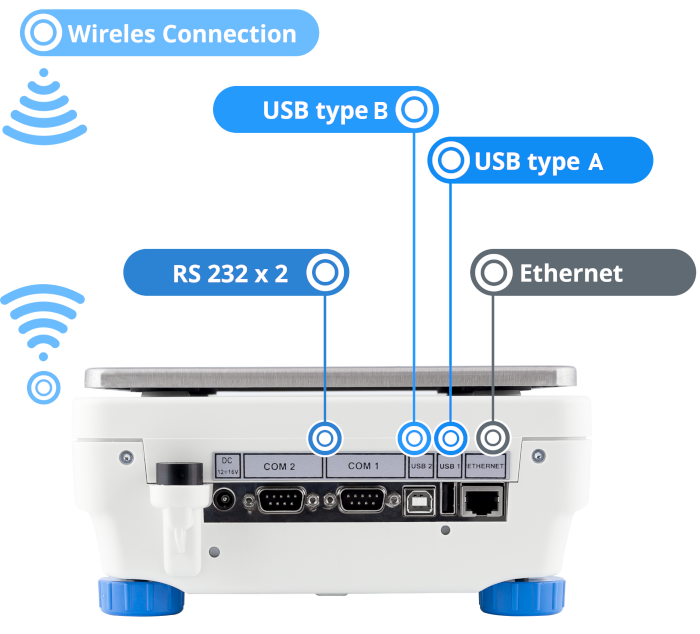

- posibilidades de comunicación ilimitadas

- memoria ALIBI con registro de mediciones

- amplias bases de datos

- máxima comodidad de manejo

- ajuste interno/externo

Personalización mediante widgets

Las balanzas de precisión WLC X7 están equipadas con múltiples interfaces de comunicación: 2 x RS232, USB-A, USB-B, Ethernet y Wi-Fi®.

La carcasa de estos dispositivos está hecha de plástico y el platillo está hecho de acero inoxidable.

Bases de datos

- Productos (5.000 bienes)

- Usuarios (100 usuarios)

- Embalaje (100 paquetes)

- Clientes (1.000 clientes)

- Recetas (100 recetas)

- Informes de recetas (500 informes)

- Condiciones ambientales (10.000 registros)

- Pesajes (50.000 registros)

- Memoria Alibi (512.000 registros).

Gestión de datos de pesaje

Memeoria ALIBI

Las balanzas compradas después del 15 de febrero de 2023 permiten realizar el pesaje bajo del platillo en cualquier momento después de la compra. Todo lo que necesita hacer es solicitar un gancho dedicado.

Learn about the use and maintenance of stainless steel products:

Stainless Steel in RADWAG products. Standard and special applications

Wi-Fi® es una marca registrada de Wi-Fi Alliance®.

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch English

English Français

Français Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文