The device is enclosed in a tight and dustproof chamber protecting it against any contamination. The air conditioning and humidification system ensures stable and fixed ambient conditions inside the chamber, which guarantees correct filters conditioning. Ambient conditions monitoring allows control of current chamber status and report of data.

Advantages:

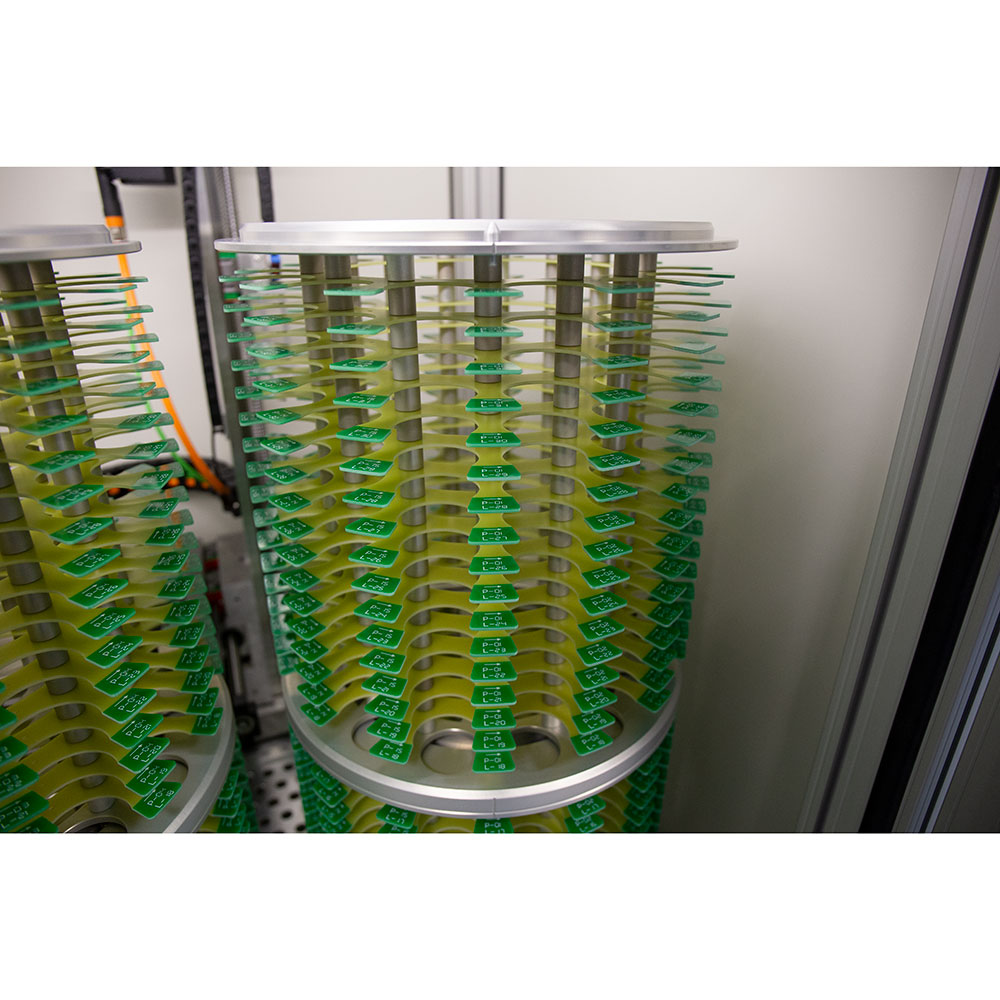

- Fully automatic system for weighing filters with Ø 47 mm

- Compliance with EN 12341:2014 standard

- Conditioning and weighing of up to 1020 filters

- Additional reference magazine

- Less time consumed when compared to manual filter weighing

- Elimination of human factor as the reason of measurement errors

- Process management using RMCS Filter software

- Automatic data recording, creating reports and statistics

- Coding and identification of filters using QR code system

- Elimination of the influence of electrostatics onto the measurement

- Hermetic robot chamber and the chamber for filter weighing

- Air conditioning system, HEPA filter (version without air conditioning on request)

- Two magazines for filter storage and weighing. Each magazine consists of 34 discs with 15 filter positions.

- A six-position reference magazine for storing mass standards and reference filters.

- A robot with a gripper enabling transport of the filters between the magazine and the microbalance, the robot moves on three axes: X,Y,Z;

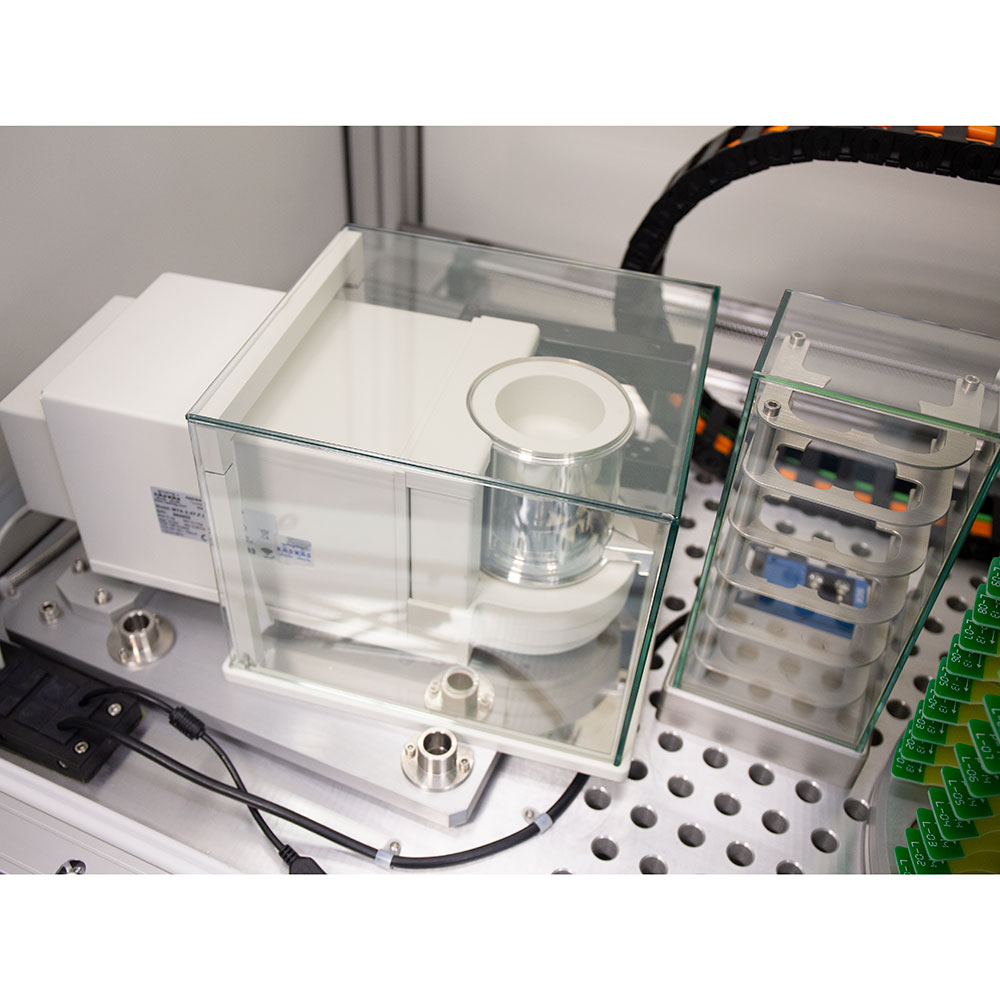

- Microbalance with a draft shield;

- Ionizing system;

- An air conditioning system with HEPA filter for cleaning the air in the vicinity of the robot chamber;

- Ambient conditions monitoring (temperature, humidity, pressure);

- Weighing indicator for managing of the device operation;

- QR code reader integrated with the device;

- QR code printers;

- A PC with the RMCS Filters software for managing the device operation;

- Control and adjustment system;

- An external air conditioning unit.

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文