Präzisionswaage WLC 6.X7

Neue Möglichkeiten

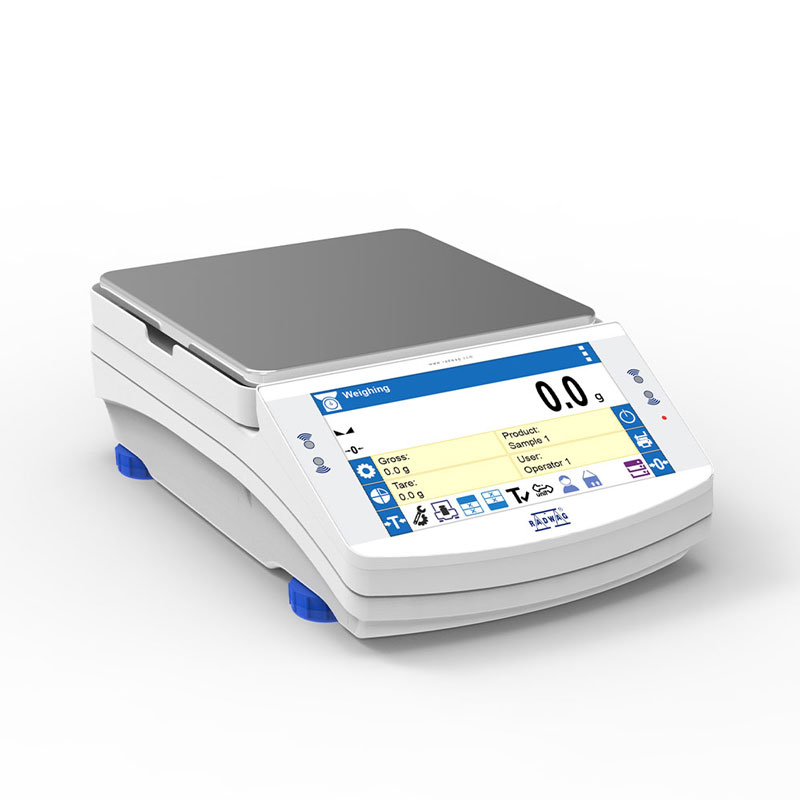

- 7"-Farb-Touchscreen

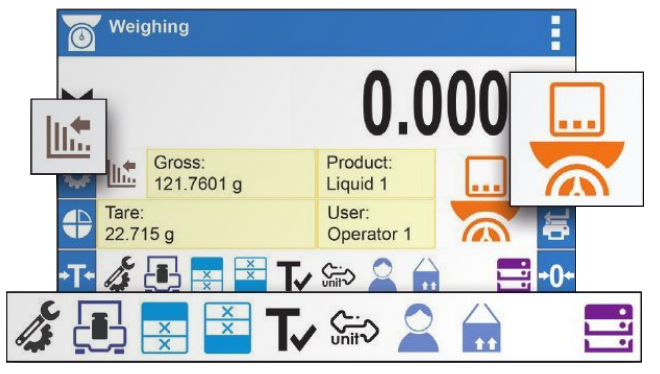

- Personalisierung des Bildschirms durch Widgets

- Mehrsprachiges, interaktives Menü

- Berührungslose Bedienungssensoren

- Konformität mit GLP- und GMP-Anforderungen

- Dynamische Gewichtskontrolle der Probe (Bargraph)

- Statistiken, Rezepturen, Berichte und Ausdrucke

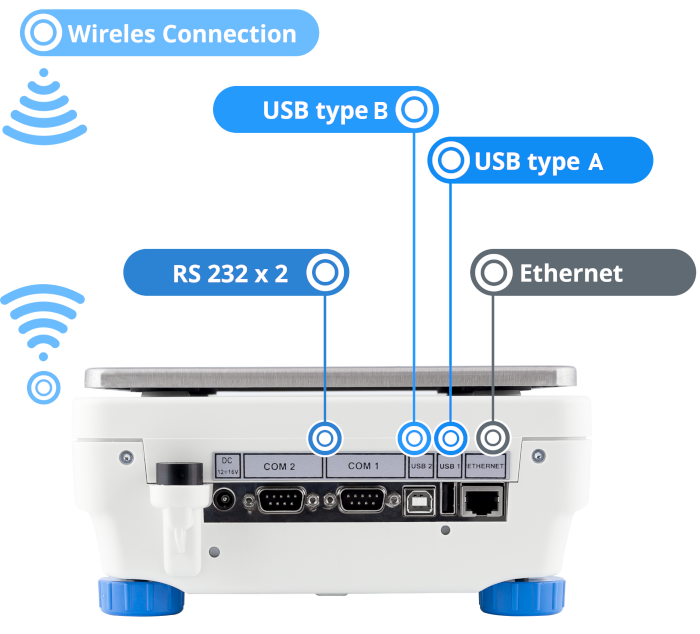

- Unbegrenzte Kommunikationsmöglichkeiten

- ALIBI-Speicher mit Messdatenerfassung

- Erweiterte Datenbanken

- Höchster Bedienkomfort

- Interne/externe Justierung

Personalisierung durch Widgets

Die Waagen sind mit mehreren Kommunikationsschnittstellen ausgestattet: 2 x RS232, USB-A, USB-B, Ethernet und Wi-Fi®.

Das Gehäuse dieser Geräte ist aus Kunststoff und die Waagschale aus Edelstahl gefertigt.

Datenbanken

Die Daten werden in 9 Datenbanken gespeichert:

- Produkte (5.000 Produkte)

- Benutzer (100 Benutzer)

- Verpackungen (100 Verpackungen)

- Kunden (1.000 Kunden)

- Rezepturen (100 Rezepturen)

- Rezepturberichte (500 Berichte)

- Umgebungsbedingungen (10.000 Datensätze)

- Wägungen (50.000 Datensätze)

- Alibi-Speicher (512.000 Datensätze).

Datenverwaltung

ALIBI--Speicher

Waagen, die nach dem 15.02.2023 gekauft wurden, ermöglichen Unterflurwägung zu einem beliebigen Zeitpunkt nach dem Kauf des Geräts. Alles, was Sie tun müssen, ist, einen speziellen Haken zu erwerben.

Erfahren Sie mehr über die Verwendung und Pflege von Edelstahlprodukten:

Rostfreier Stahl in RADWAG-Produkten. Standard- und Spezialanwendungen

Wi-Fi® ist eine eingetragene Marke der Wi-Fi Alliance®.

Prüfen Sie den Preis in unserem Shop

radwagwaagen.de

Einkäufe direkt beim Hersteller bieten nur Vorteile

Sie erhalten stets die aktuelle Version des Geräts und der Software. Unsere Produkte werden kontinuierlich verbessert.

Direkter Support von den Entwicklern des Produkts. Wer könnte besser Ihre Fragen beantworten? Liken Sie unser Facebook-Profil und bleiben Sie mit uns in Kontakt.

Sorgfältig verpackt legt das Paket nur einen Weg zurück – den zu Ihnen.

In unserem umfassenden Angebot finden Sie Zubehör wie Kabel, Wiegeschalen, Netzteile und alle Ersatzteile für unsere Waagen. Zudem führen wir Legalisierungs- und periodische Inspektionen in unserem Labor durch.

Sie erwerben ein in Europa entwickeltes und hergestelltes Produkt – somit erhalten Sie ein Gerät mit einem definierten Standard an Konformität.

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin English

English Español

Español Français

Français Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky Português (Brasil)

Português (Brasil) USA

USA 中文

中文