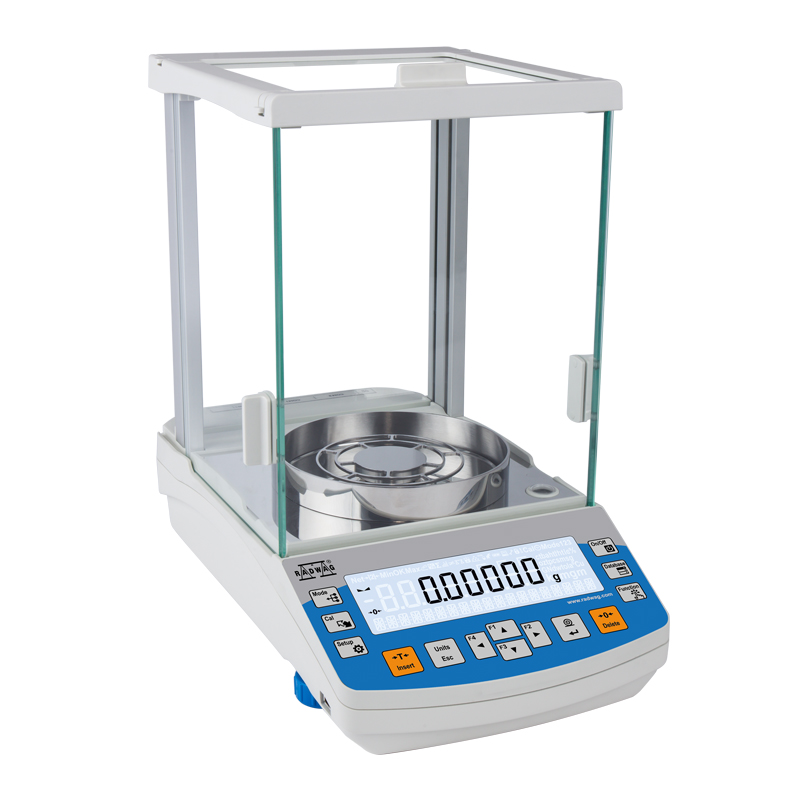

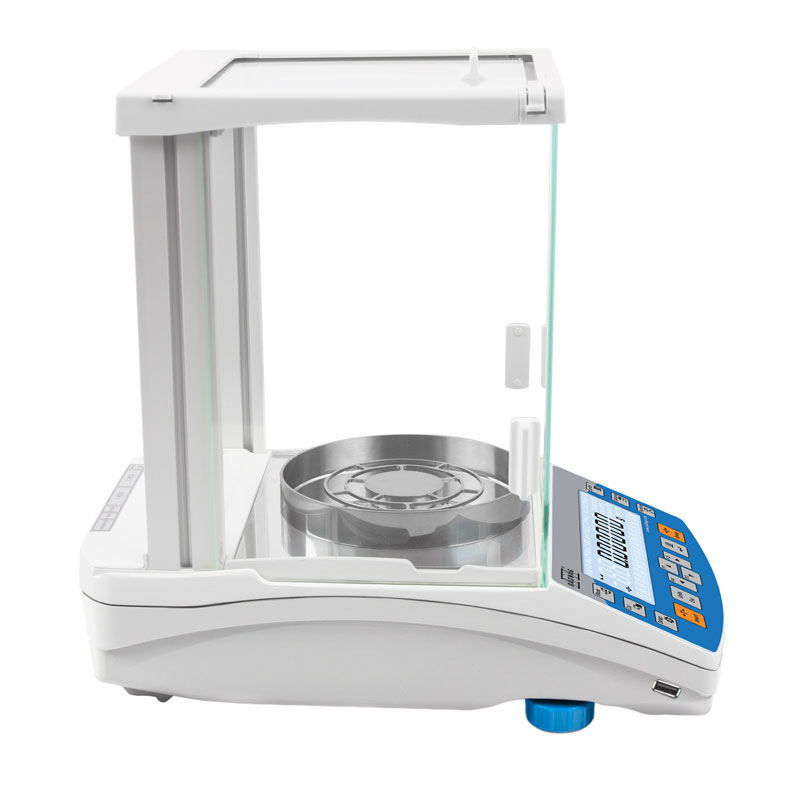

Analysenwaage AS 60/220.R2 PLUS

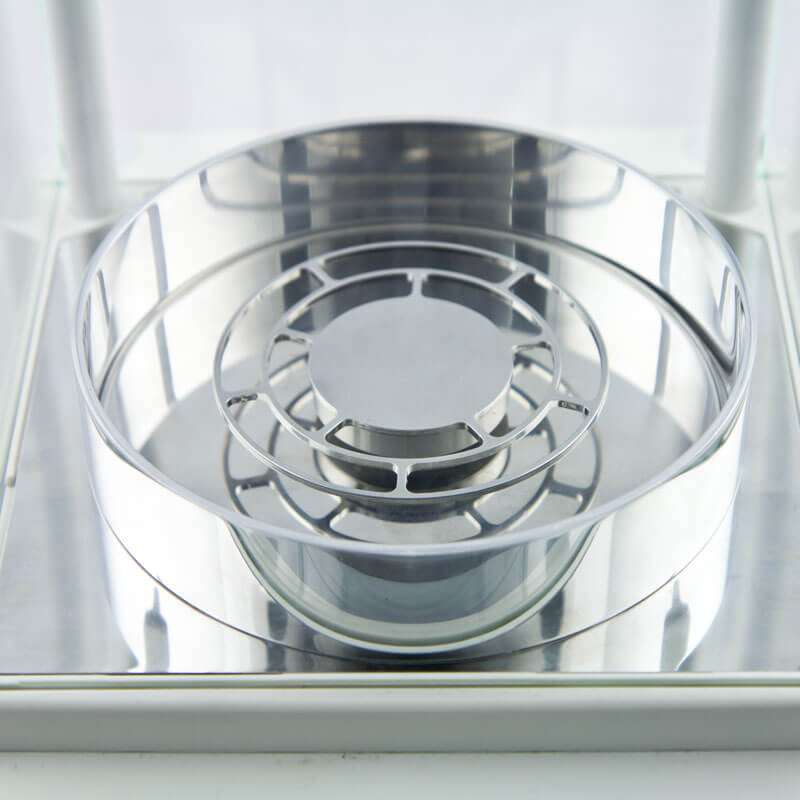

Ergonomisches mechanisches Design

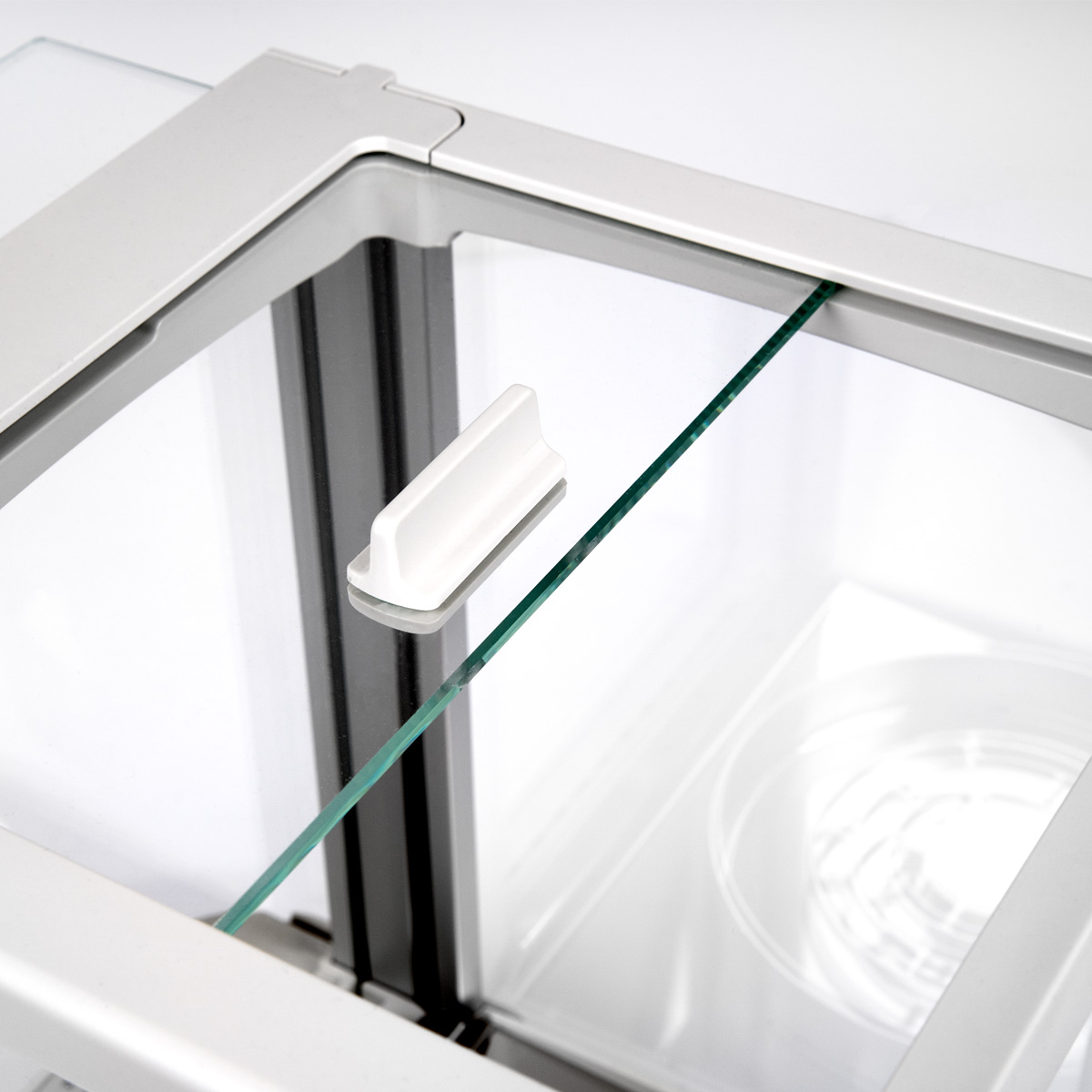

Das Dual-CLICK-System ermöglicht eine werkzeuglose Montage und Demontage der Wägekammer, und ein spezielles Design der Führungen für die Scheiben (ohne Ränder) erleichtert die Reinigung des Geräts.

Innovative Konstruktionslösungen erhöhen die Haltbarkeit und Zuverlässigkeit der Waage im Langzeitbetrieb.

Nivelliersystem

Intuitive Bedienung

- Datenbank – direkter Zugriff auf die Datenbanken

- Funktion – direkter Zugriff auf die Grundfunktionen

- F1-F4 – programmierbare Funktionstasten und Menünavigationstasten.

Interne Justierung

Ein modernisiertes internes Justiersystem garantiert genaue Anzeigen, auch unter extrem ungünstigen Bedingungen.

Schutz der Daten

ALIBI-Speicher

Datenbanken

Die Daten werden in 5 Datenbanken registriert:

- Betreiber (bis zu 10 Benutzer),

- Produkte (bis zu 1000 Produkte),

- Wägungen (bis zu 5000 Wägungen),

- Taras (bis zu 100 Taras),

- ALIBI-Speicher (bis zu 100 000 Wägungen).

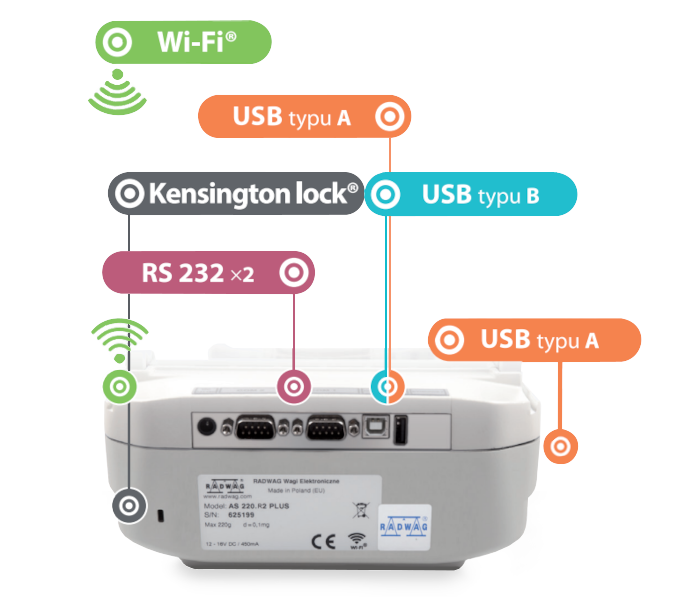

Kommunikationsschnittstellen

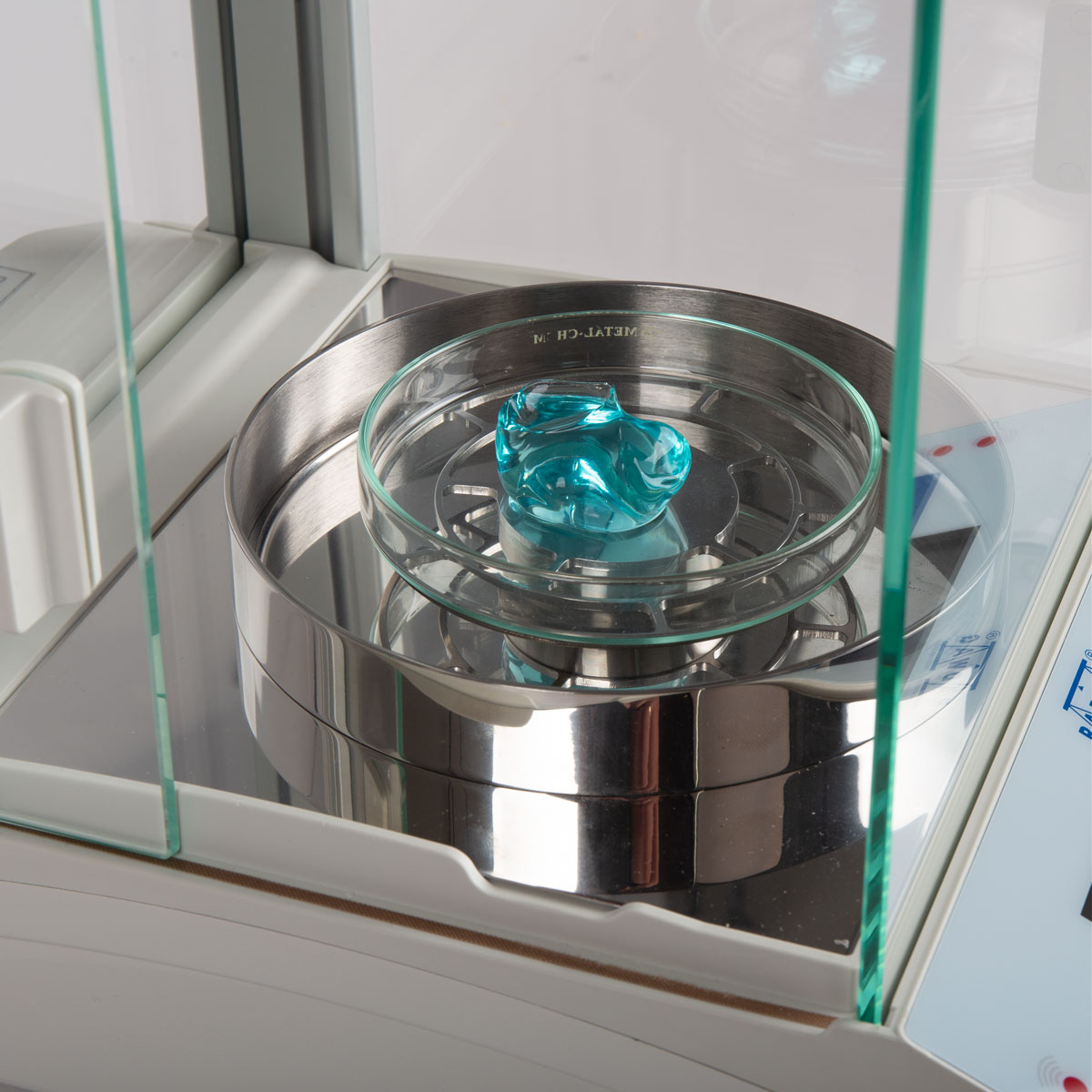

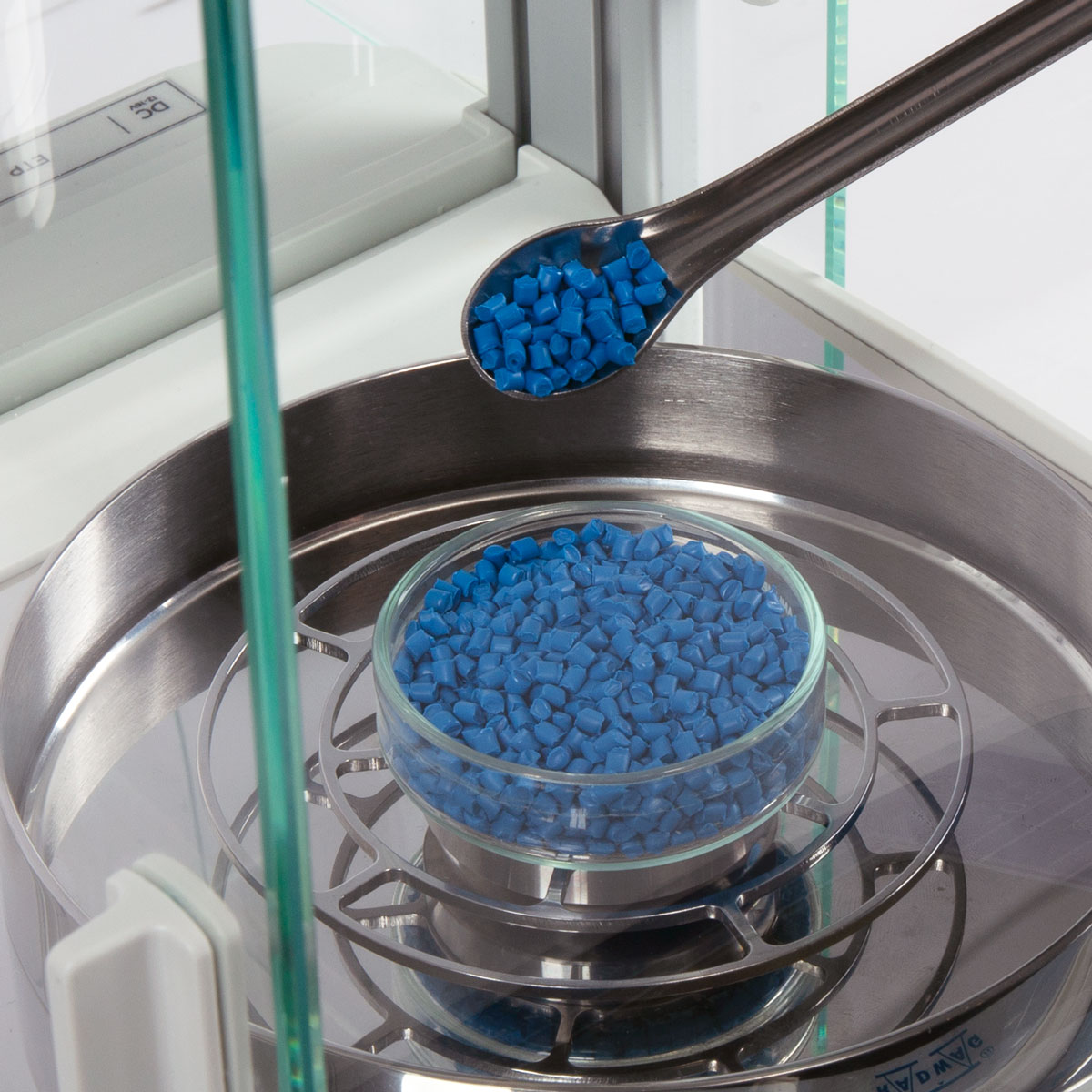

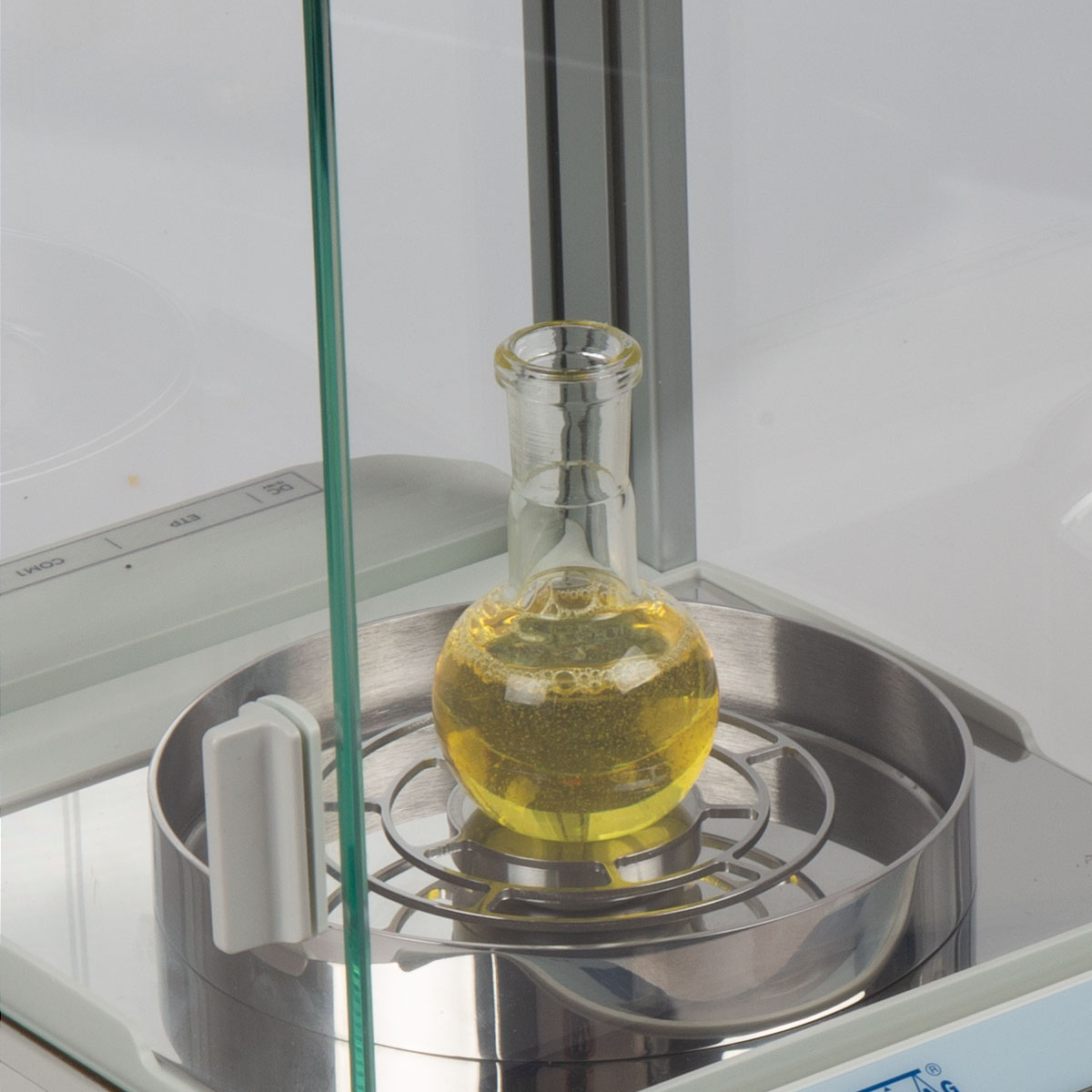

Erfahren Sie mehr über die Verwendung und Pflege von Edelstahlprodukten:

Rostfreier Stahl in RADWAG-Produkten. Standard- und Spezialanwendungen

Wi-Fi® ist eine eingetragene Marke der Wi-Fi Alliance®.

Additional fee

Additional fee

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) English

English Español

Español Français

Français Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文