MYA 31.5Y Microbalance

What Are the Benefits of Choosing MYA Microbalances?

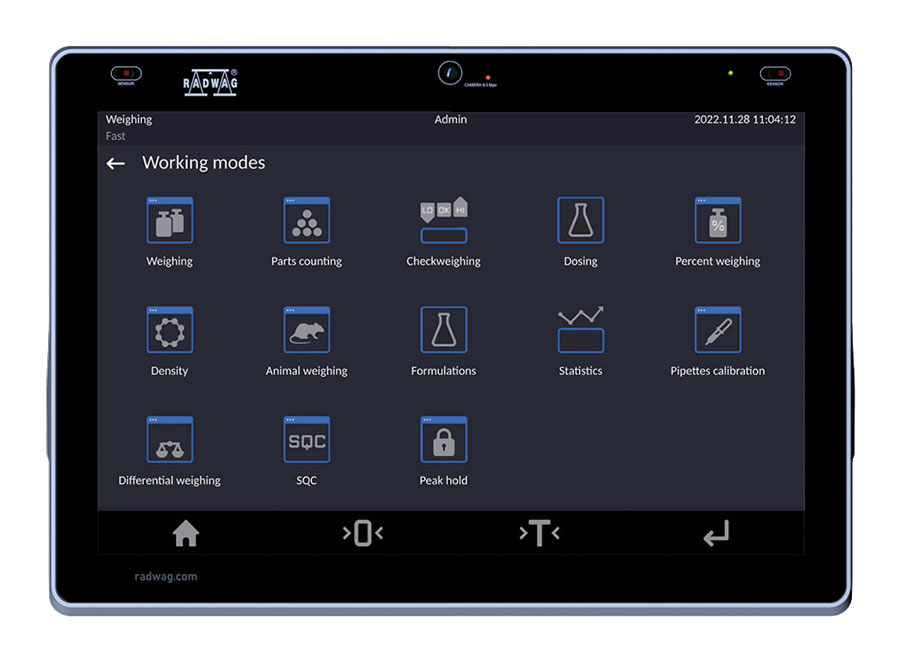

If so, learn about the functionality of the ELLIPSIS series of balances:

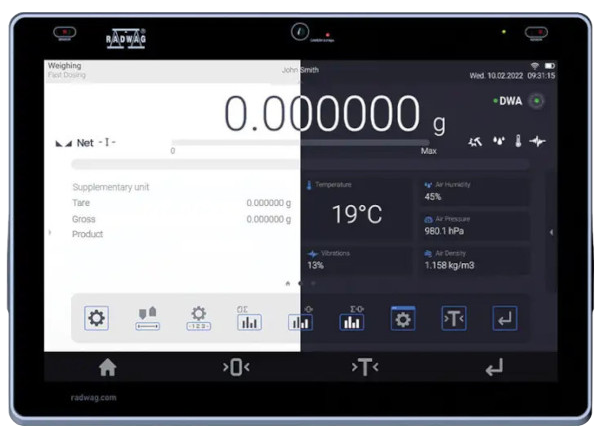

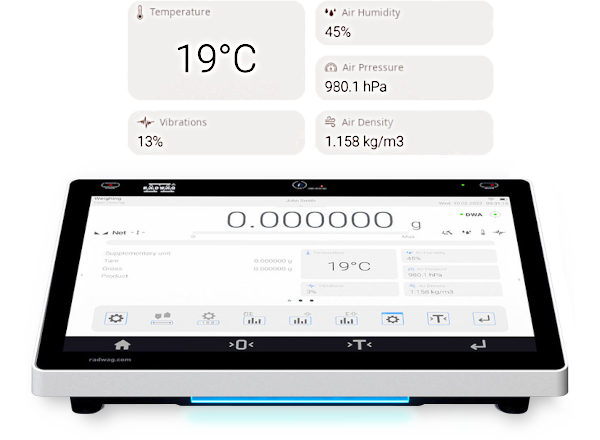

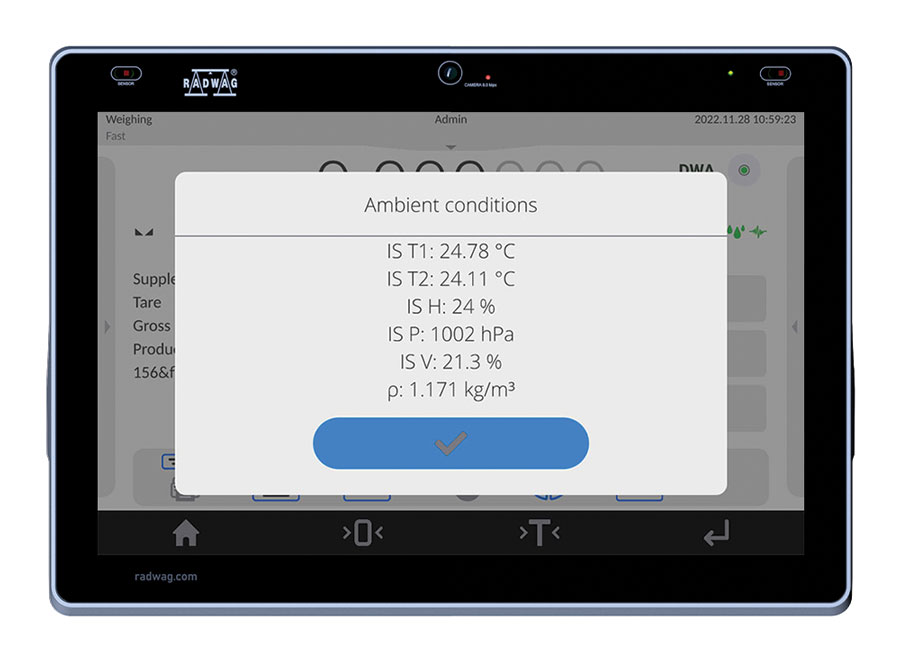

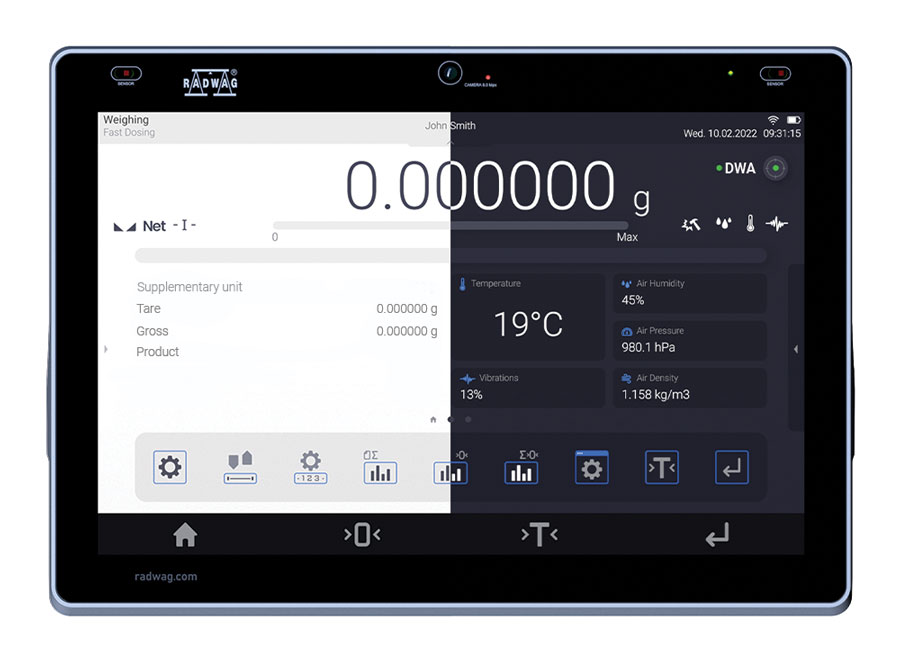

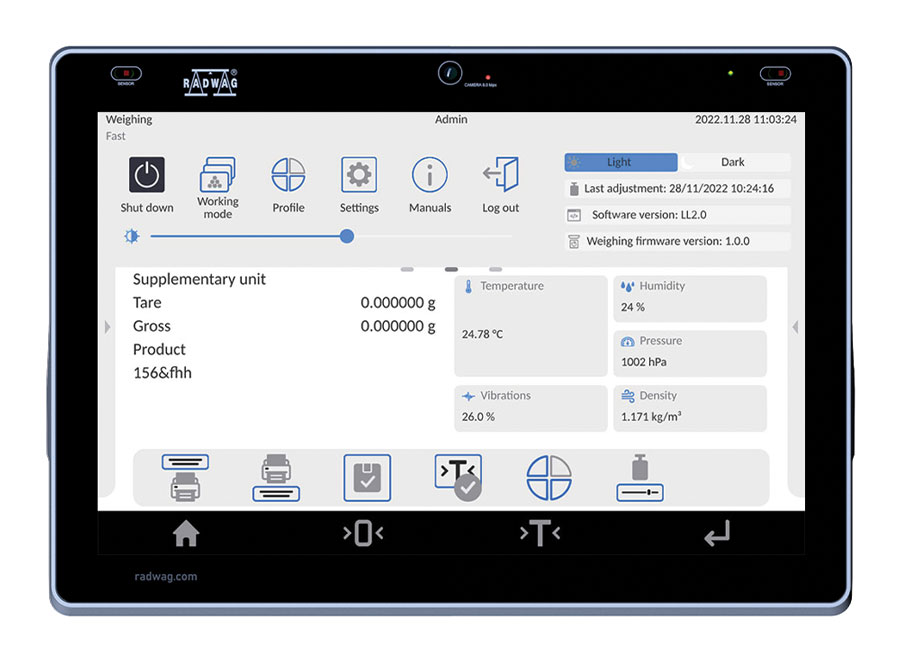

Digital Weighing Auditor

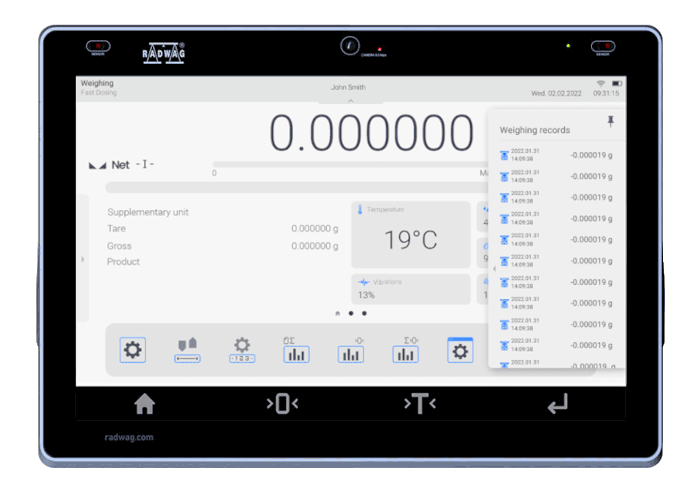

10-Inch Display

Uncompromising User Verification

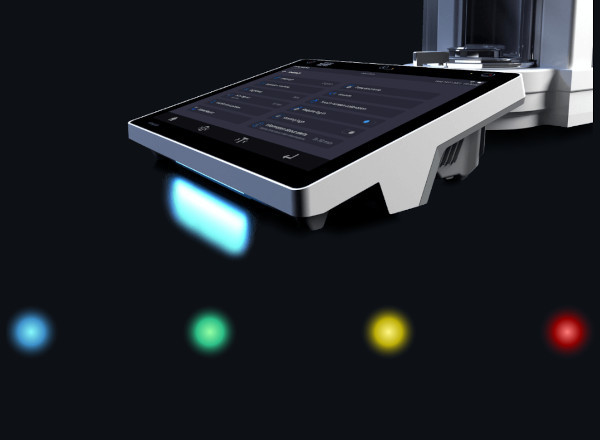

Ambient Light – An Innovative Way for the Balance to Communicate With the User

Hotspot

RFID

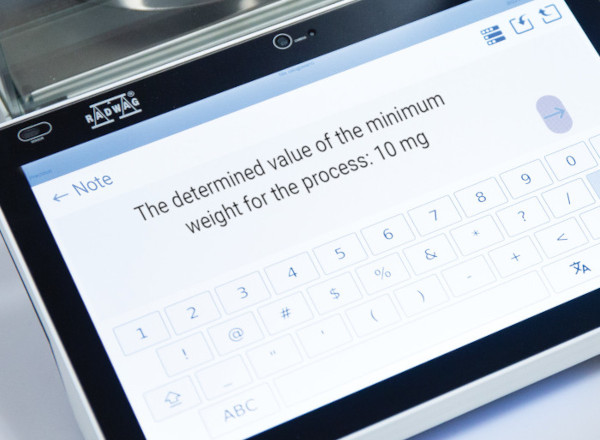

Live Note – Note Down Your Conclusions

Handy Library

Widgets

Automatic Leveling of the Balance ReflexLEVEL System

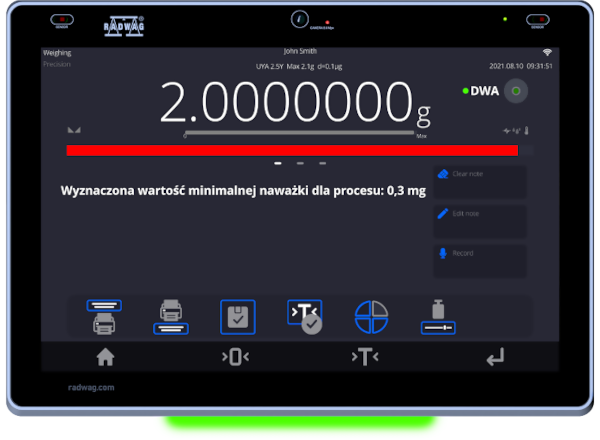

Smart Min Weight

21 CFR Part 11

We are offering the laboratory balance which as a standalone fully meets the requirements of 21 CFR Part 11/ EU GMP Annex 11.

– Electronic signatures

– Validations

– Electronic records

– Audit trails

Modbus TCP/IP

Two-point adjustment

* RFID ISO/IEC 14443 Type A, 13.56 MHz

Additional fee

Additional fee

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch English

English Español

Español Français

Français Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky 中文

中文