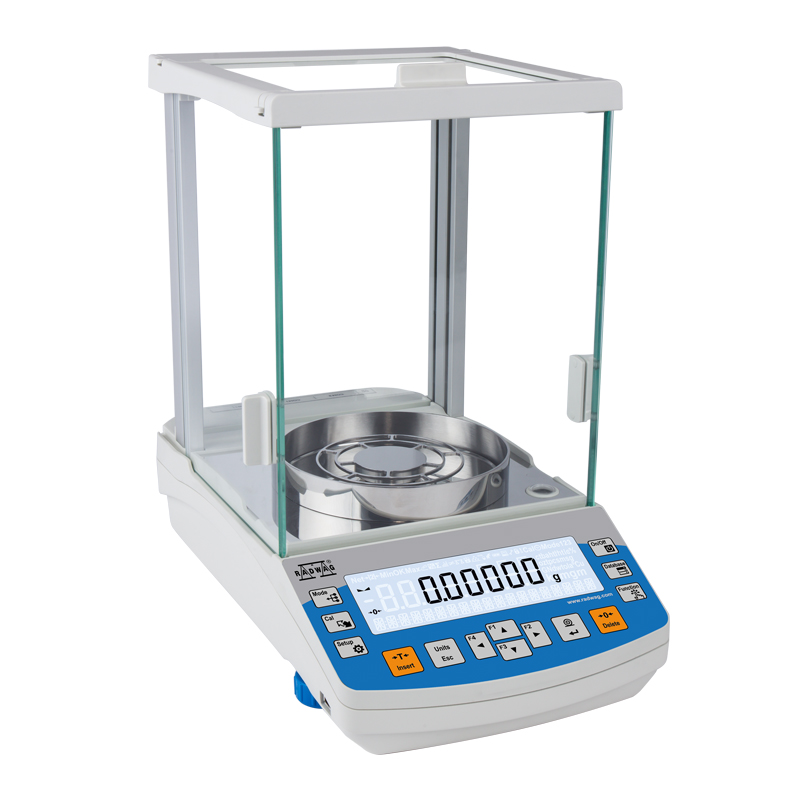

AS 60/220.R2 PLUS Analytical Balance

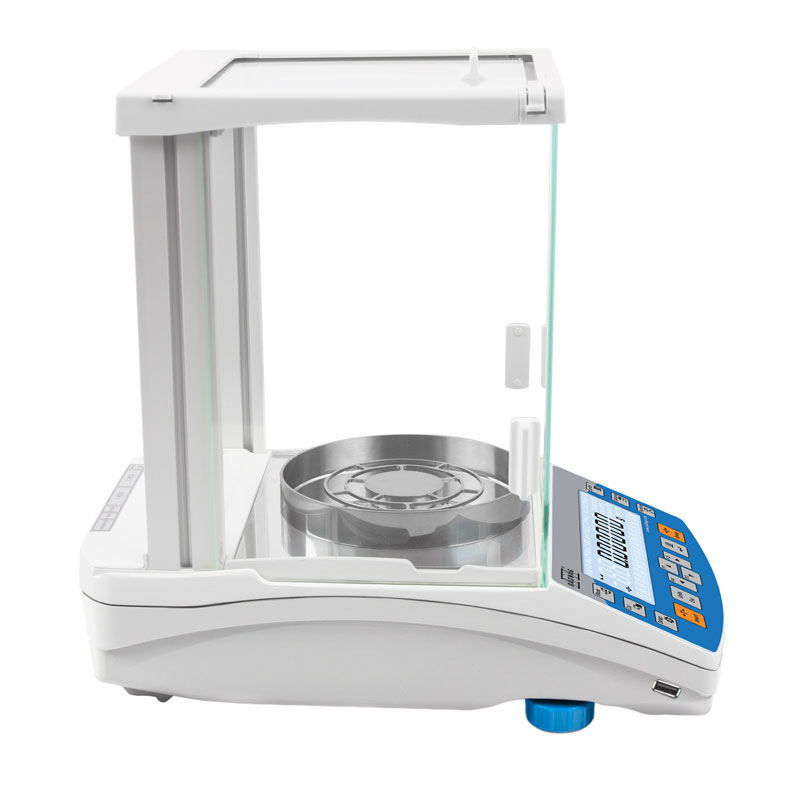

Ergonomic Mechanical Design

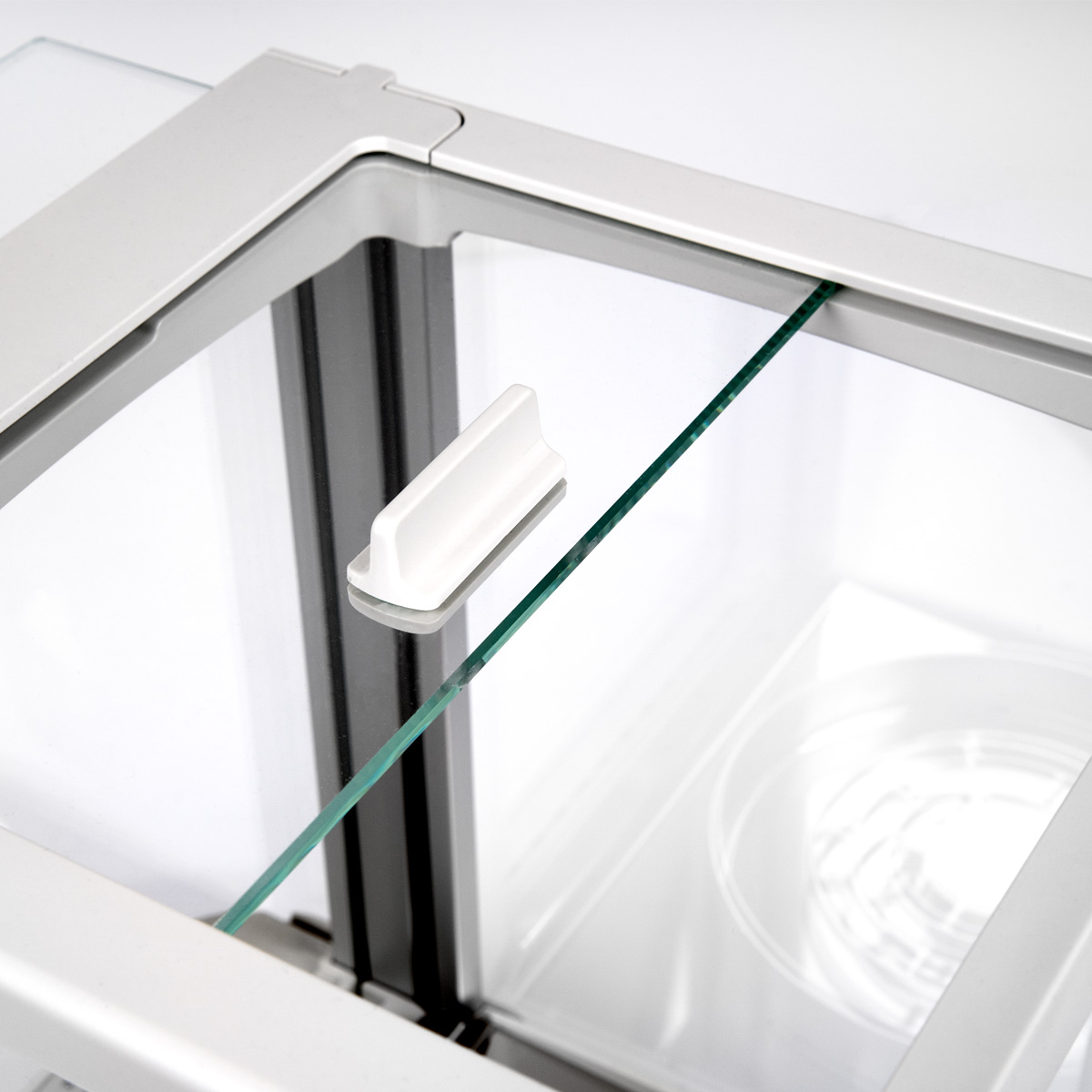

Dual-CLICK system allows tool-free assembly and disassembly of the weighing chamber, and a special design of guides for weighing chamber panes (no rims) makes keeping the device clean convenient.

Innovative construction solutions increase balance durability and reliability in long-term operation.

Levelling System

Intuitive Operation

- Database – direct access to databases,

- Function – direct access to basic functions,

- F1-F4 – programmable function keys and menu navigation keys.

Data Protection

ALIBI Memory

Databases

- operators (up to 10 users),

- products (up to 1000 products),

- weighings (up to 5000 weighings),

- tares (up to 100 tares),

- ALIBI memory (up to 100 000 weighings).

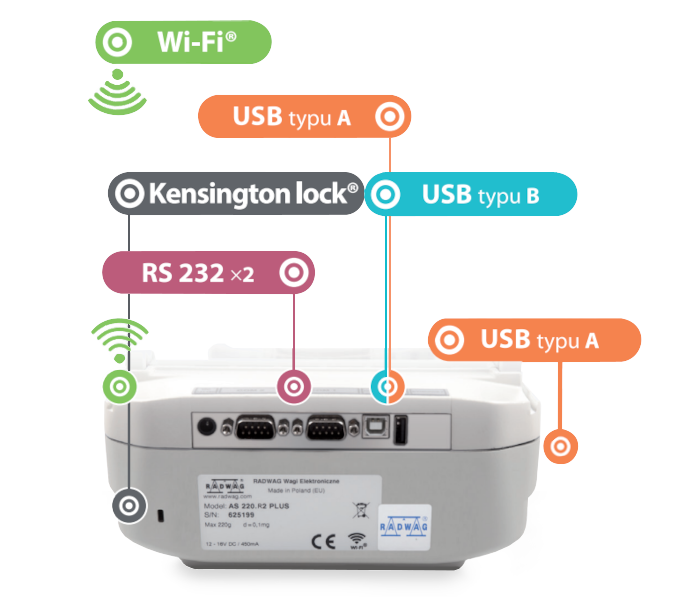

Communication Interfaces

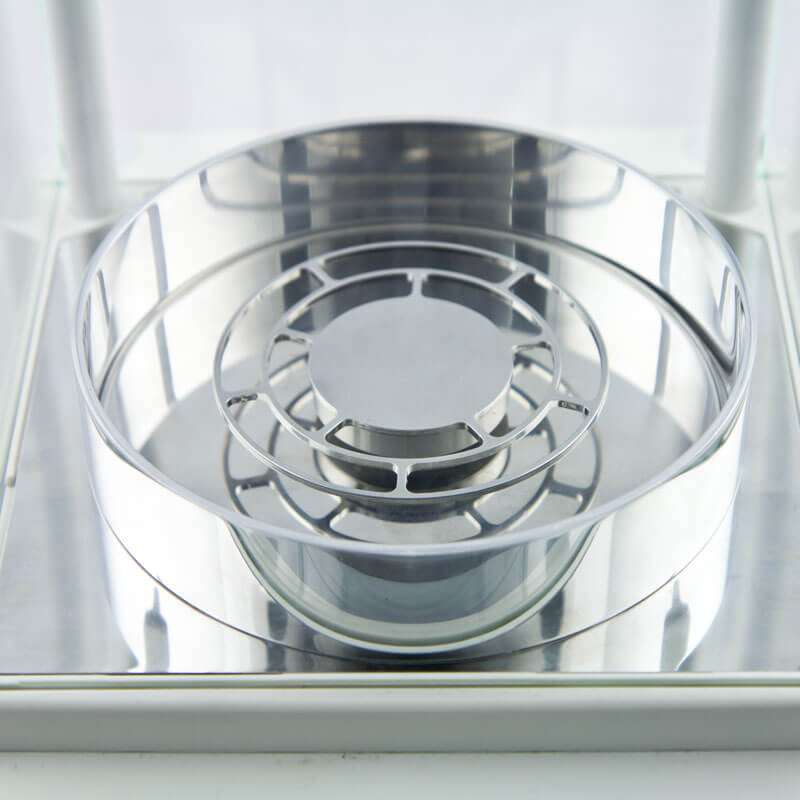

Learn about the use and maintenance of stainless steel products:

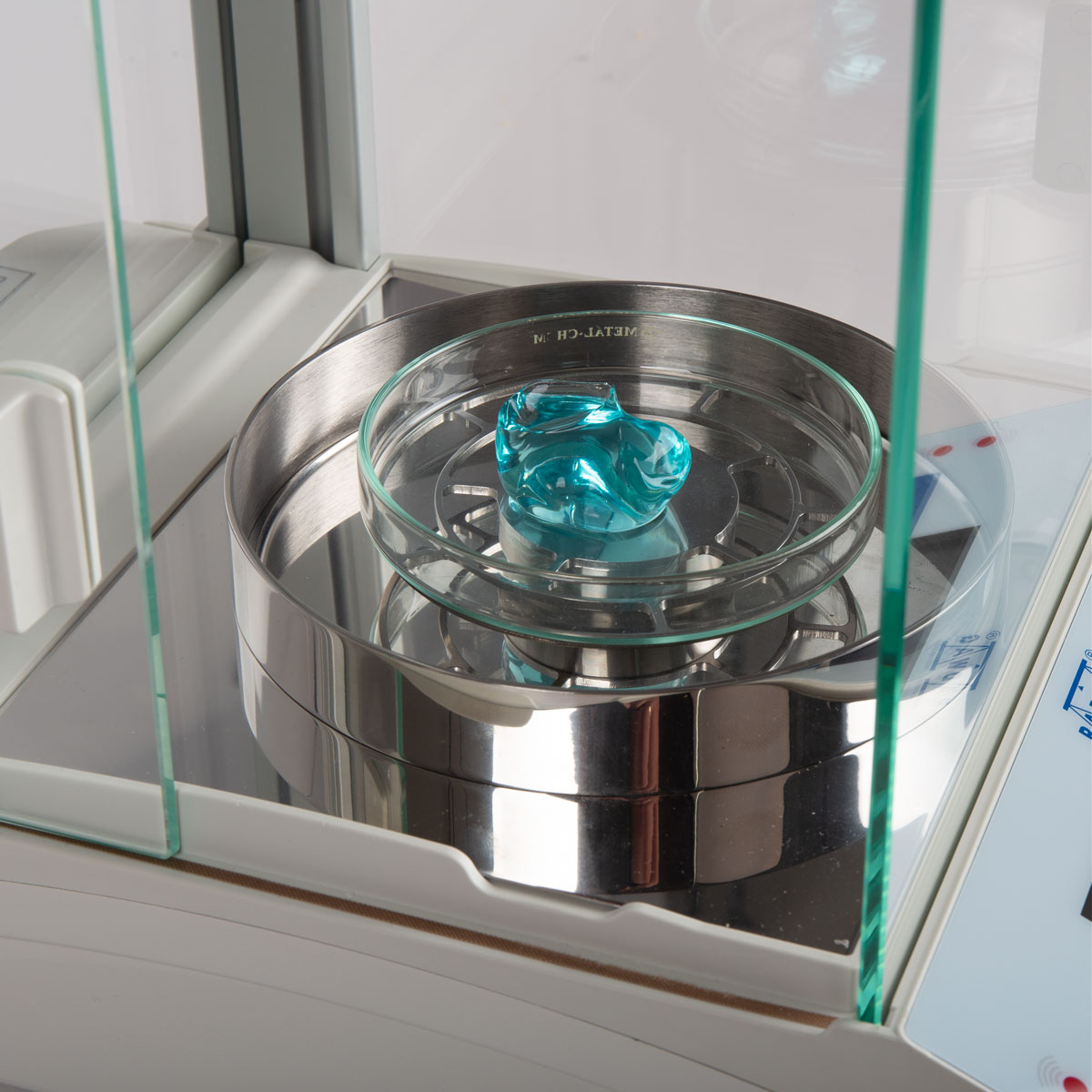

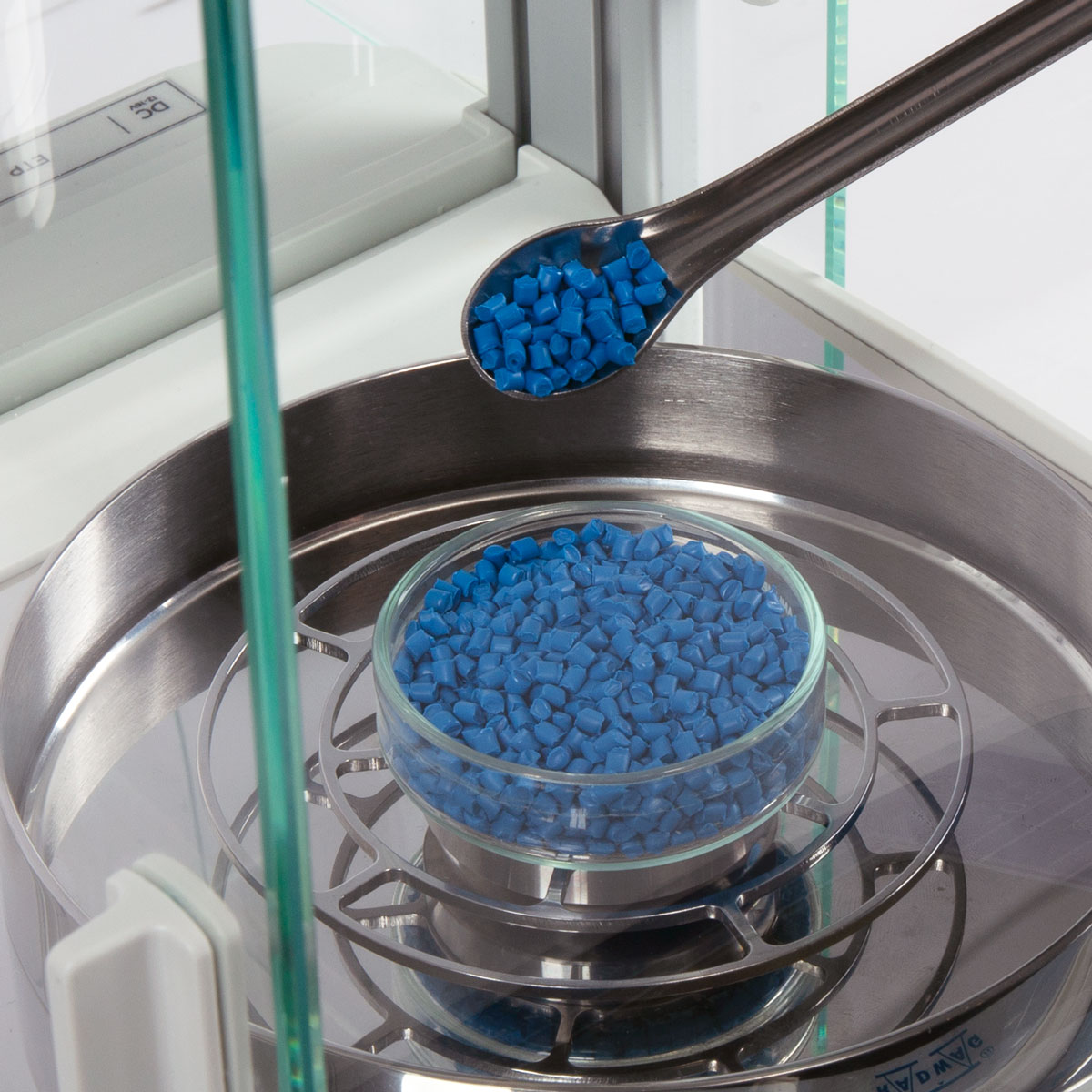

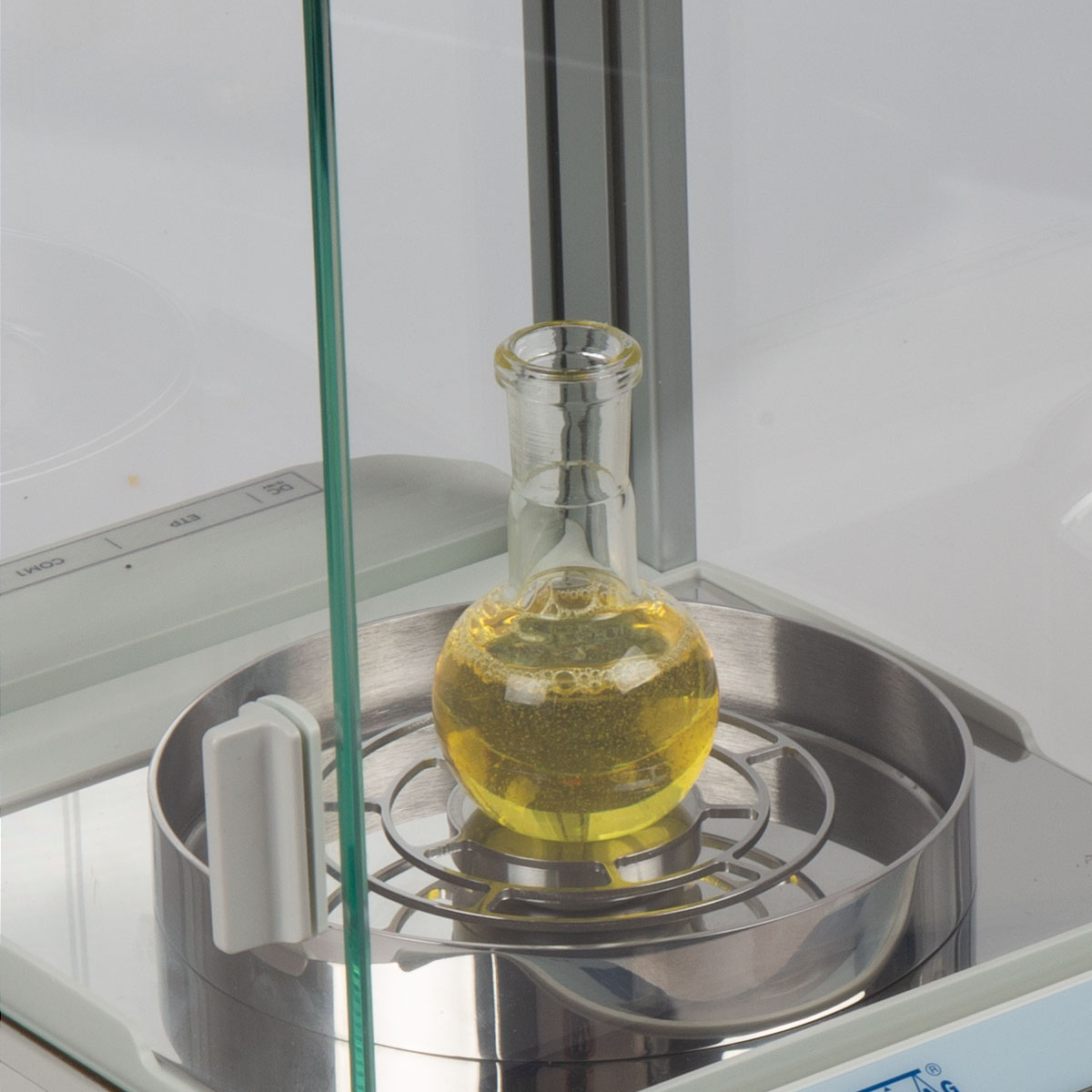

Stainless Steel in RADWAG products. Standard and special applications

Wi-Fi® is a registered trademark of Wi-Fi Alliance®.

Additional fee

Additional fee

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch English

English Español

Español Français

Français Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky 中文

中文