PS 3000.X2 上皿天秤

シリーズ PS.X2

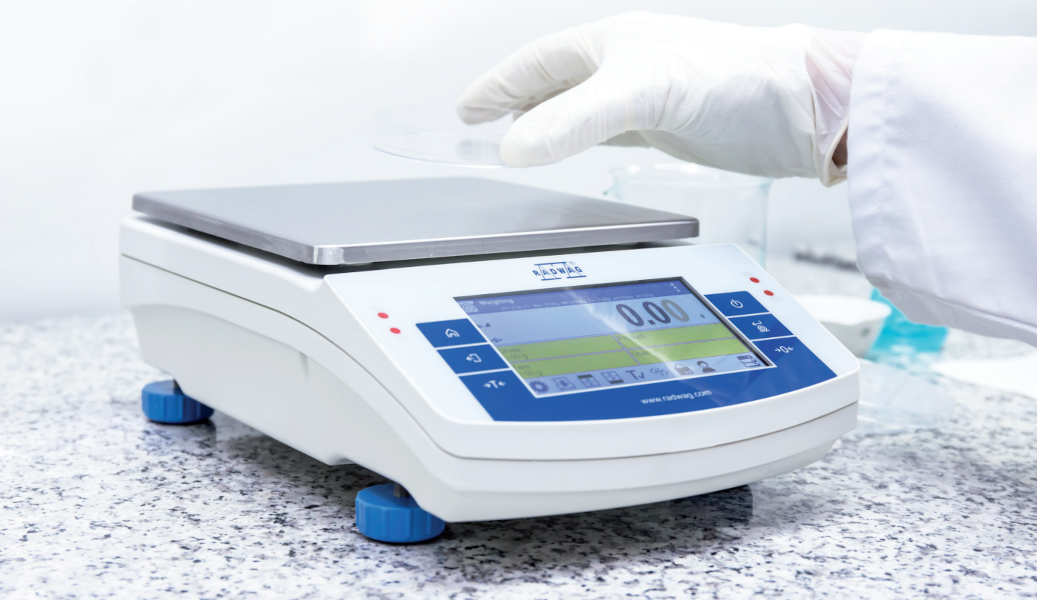

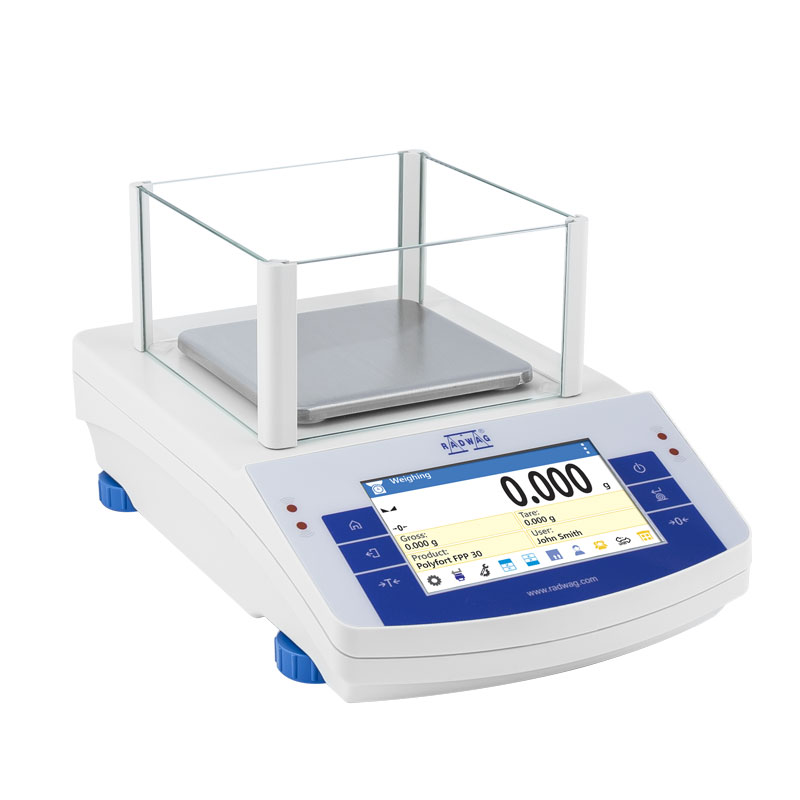

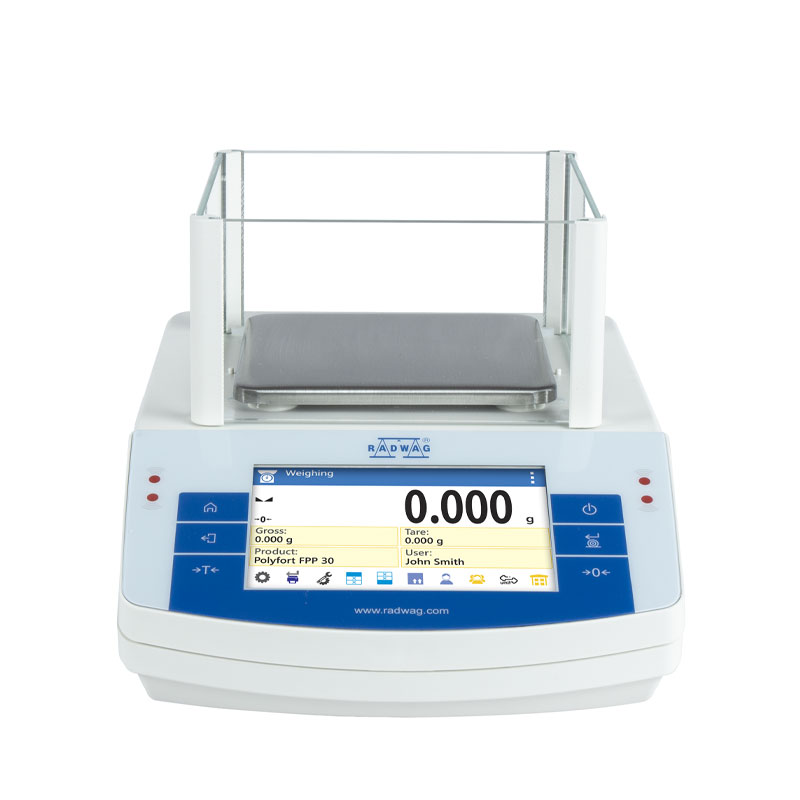

X2シリーズの天びんは、最新世代の静電容量式ディスプレイを搭載し、直感的な操作性と快適な使用感を実現します。操作のしやすさ、分かりやすいメニュー、実用的なディスプレイ配置により、日々の作業の最高のエルゴノミクス(人間工学)を保証します。

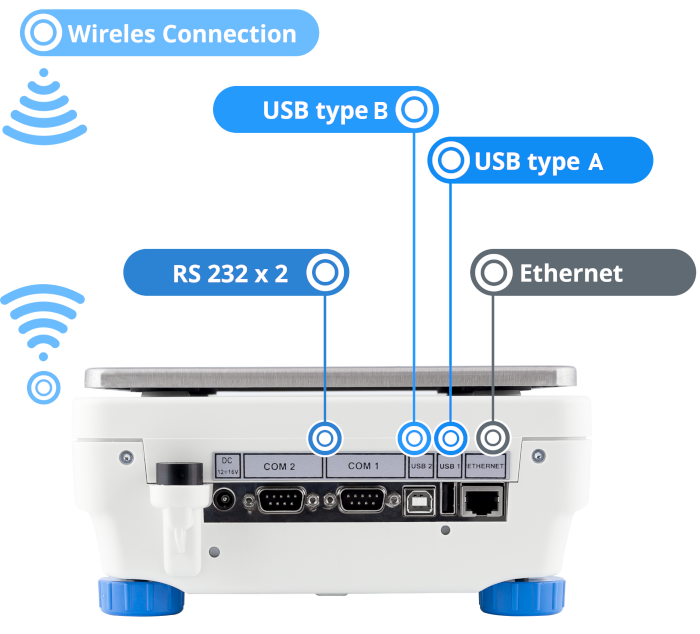

また、多彩なインターフェースを備えており、最適な通信手段を自由に選択できます。

パーソナライズの新次元

X2シリーズの天びんは、印刷、コピー、データのアーカイブ、データ転送など外部デバイスとの連携において無限の可能性を提供します。

内蔵のIRセンサーにより、手をかざすだけで、風袋引き、計量結果のプリンター送信、特定のプロセスのステップ選択などの操作が可能です。本体はプラスチック製、計量パンはステンレス製です。

Databases in X2 series balances

データは以下の9つのデータベースに保存されます:

- 製品(5,000件)

- ユーザー(100人)

- 包装(100種類)

- 顧客(1,000件)

- 調合(100件)

- 調合レポート(500件)

- 周囲環境データ(10,000件)

- 計量記録(50,000件)

- ALIBIメモリ(512,000件)

計量データ管理

ALIBIメモリー

ALIBIメモリには、最大 500,000件 の計量データを保存可能です。

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch English

English Español

Español Français

Français Italiano

Italiano Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文