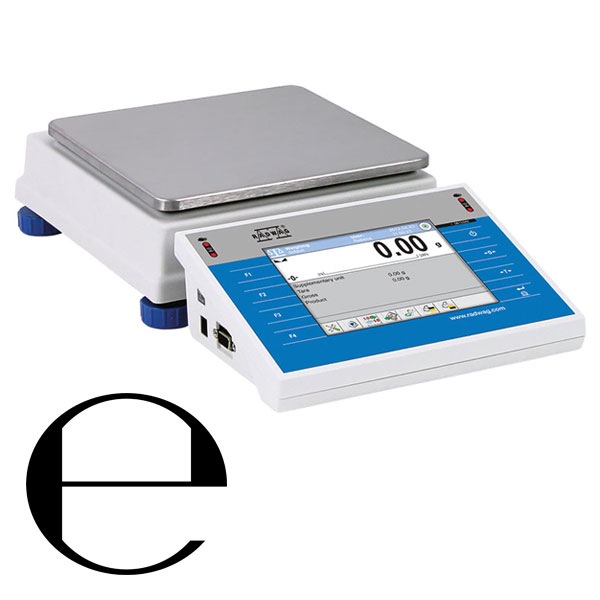

Bilancia WPY per controllo statistico

La procedura di controllo segue lo schema seguente:

- scelta dell’operatore,

- scelta del prodotto,

- inzio del controllo,

- acquisizione dei valori delle pesate,

- il controllo finisce quando sono stati pesati il numero di campioni predefinito,

- stampa del rapporto di prova.

La bilancia unita al programma permette:

- mantenere i campi relativi alle pesate nel database,

- stampa automatica del processo di controllo direttamente dal PC

- inviare codici definiti dall’operatore dalla bilancia al PC; i codici corrispondono ai prodotti pesati (codici prodotto, codici operatore, numerosita del lotto, numero di lotto, controllo di INIZIO/FINE),

- definire i codici realtivi ai prodotti e la loro descrizione direttamente da compute. In questo modo un operatore puo assegnare una specifica descrizione del prodotto utile relativa alla divisione aziendale di appartenenza.

Learn about the use and maintenance of stainless steel products:

Stainless Steel in RADWAG products. Standard and special applications

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Deutsch

Deutsch English

English Español

Español Français

Français Polski

Polski Türkiye

Türkiye Česky

Česky Português (Brasil)

Português (Brasil) USA

USA 中文

中文