Bilancia di precisione PS 600.R2.1

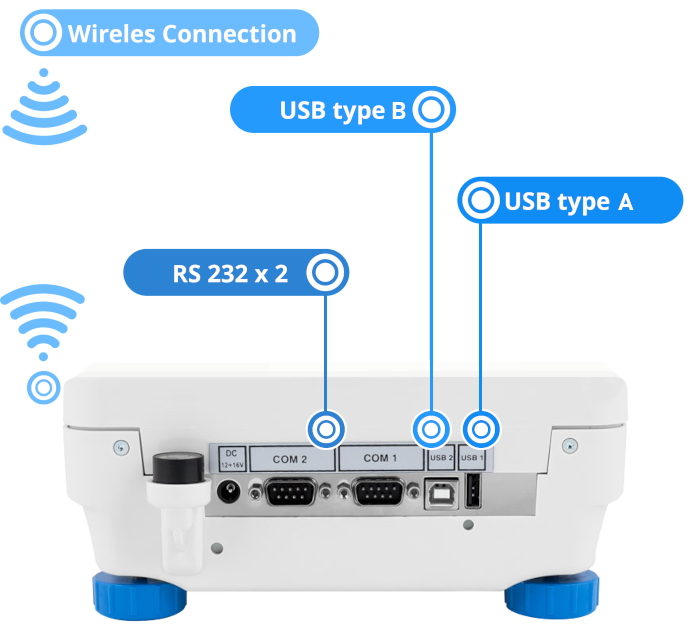

Interfacce

2 x RS 232, USB A, USB B e della connessione „Wireless” (opzionale).

Le nuove bilance di precisione serie PS.R2, similamente alla vecchia serie PS dispongono di due tipi di piatto di pesata con dimensioni diverse: 128x128 mm o 195x195 mm. Le bilance con il piatto di dimensioni minore dispongono di uno chermo anti correnti d’aria. La precisione della bilancia e l’accuratezza della misura viene assicurato da un sistema di calibrazione interna che misura i cambiamenti della temperaura. La calibrazione viene eseguita ad intervalli di tempo prefissati ed ogni volta che il cambiamento della temperatura supera i limiti impostati

La struttura e costruita in materaile plastico ed il piatto di pesata e in acciaio inox.

Database

I dati sono registrati in 5 database:

- utilizzatori (fino a 100 utilizzatori),

- prodotti (fino a 1000 prodotti),

- pesate (fino a 5000 pesate),

- tare (fino a 100 tare),

- memoria ALIBI (fino a 100 000 pesate).

Accesso veloce alle informazioni

- Database – accesso diretto ai database

- Function – accesso di retto alle funzioni di base

- Da F1 a F4 – Funzioni programmabili e pulsanti di navigazione sul menu

Le bilance possono essere connesse ad un PC per mezzo dell’interfaccia USB laddove venga installato sul PC un software dedicato (o un driver). Il cosidetto driver puo essere scaricato direttamente dal sito Radwag nella sezione „SUPPORTO”

Memoria ALIBI

Learn about the use and maintenance of stainless steel products:

Stainless Steel in RADWAG products. Standard and special applications

Additional fee

Additional fee

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Deutsch

Deutsch English

English Español

Español Français

Français Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky Português (Brasil)

Português (Brasil) USA

USA 中文

中文