Balance multifonctionnelle WPY 30/C2/K

D’interfaces

Le module Workflow

La balance

Learn about the use and maintenance of stainless steel products:

Acier inoxydable dans les balances RADWAG

Balance multifonctionnelle WPY 30/C2/K

⤢

400×500mm⤢

300×300mm⤢

300×300mm⤢

300×300mm⤢

300×300mm⤢

300×300mm⤢

300×300mm⤢

300×300mm⤢

300×300mm⤢

300×300mm⤢

400×500mm⤢

400×500mm⤢

500×700mm⤢

500×700mm⤢

300×300mm⤢

300×300mm⤢

300×300mm⤢

400×500mm⤢

400×500mm⤢

500×700mm⤢

500×700mm⤢

300×300mm⤢

300×300mm⤢

300×300mm⤢

400×500mm⤢

400×500mm⤢

400×500mm⤢

500×700mm⤢

500×700mm⤢

400×500mm⤢

400×500mm⤢

400×500mm⤢

500×700mm⤢

500×700mm⤢

400×500mm⤢

400×500mm⤢

400×500mm⤢

500×700mm⤢

500×700mm⤢

400×500mm

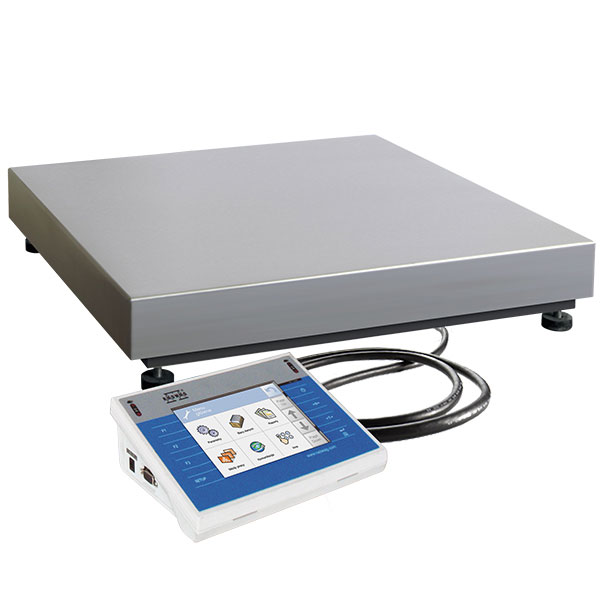

| Capacité maximale [Max] | 30 kg |

| Capacité minimale [Min] | 200 g |

| Précision de lecture [d] | 10 g |

| Étendue de tare | -30 kg |

| Précison de lecture maximale pour les balances non vérifiées | 1 g |

| Temps de stabilisation | 2 s |

| Ajustage | externe

|

| Classe de précision OIML | III

|

| Afficheur | 5,7” Écran tactile couleur résistif

|

| Dimension du plateau | 400×500 mm |

| Dimensions de colis | 720×620×210 mm |

| Masse nette | 11,1 kg |

| Masse brute | 13,1 kg |

| Degré de protection | IP 65 construction, IP 43 terminal

|

| Interface de Communication | 2×RS232, 2×USB-A, Ethernet, 4 IN / 4 OUT (numériques), Wi-Fi®

|

| Alimentation | 100 – 240 V AC 50/60 Hz

|

| Température du travail | -10 – +40 °C |

This site uses files of cookies for statistical, advertising and functional purposes.

By using this website, you consent to our use of cookies in accordance with the principles of our Privacy Policy.

Additional fee

Additional fee