Il existe la possibilité de construire la balance à bi-échelon pour un paiement supplémentaire.

Learn about the use and maintenance of stainless steel products:

Acier inoxydable dans les balances RADWAG

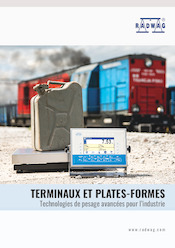

Pèse-Poutre C315.4P2.4000.C1

⤢

2 pièces 2m⤢

2 pièces 1,2m⤢

2 pièces 1,2m⤢

2 pièces 2m⤢

2 pièces 2,5m⤢

2 pièces 1,2m⤢

2 pièces 2,5m⤢

2 pièces 2,5m⤢

2 pièces 2m| Capacité maximale [Max] | 4000 kg |

| Capacité minimale [Min] | 40 kg |

| Précision de lecture [d] | 2000 g |

| Étendue de tare | -4000 kg |

| Classe de précision OIML | III

|

| Afficheur | LCD (rétro-éclairé)

|

| Longueur de câble | 3 m + 5 m

|

| Dimension du plateau | 2 pièces 2 m |

| Dimensions d'appareil | 2000×120×155 mm |

| Masse de balance avec le terminal | 90 kg |

| Degré de protection | IP 65 construction, IP 67 tensomètre, IP 43 terminal

|

| Interface de Communication | RS232

|

| Interfaces optionnelles | RS232

|

| Alimentation | 100 – 240 V AC 50/60 Hz + accumulateur

|

| Prise de courant maximale | 5 W

|

| Temps de travail avec l'alimentation d'accumulateur | max 8h

|

| Température du travail | -10 – +40 °C |

| Humidité relative d'air | 10% – 85% RH sans condensation

|

Additional fee

Additional fee