Báscula multifuncional TMX15IR.150.H4.K

TMX H

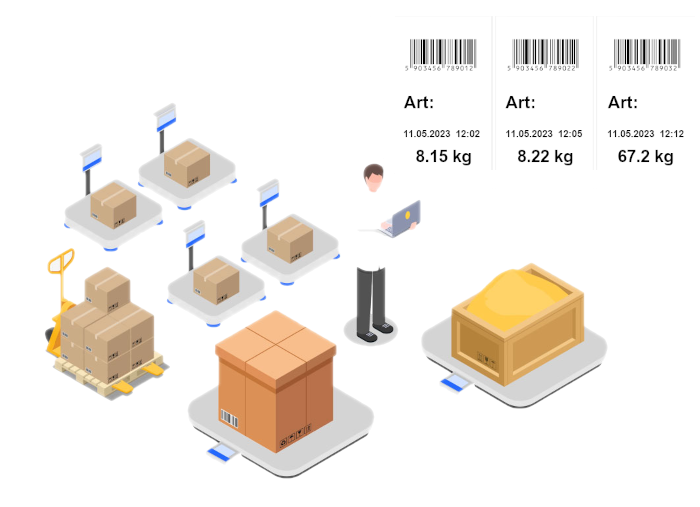

Funcionalidad del software:

- función de control de peso (control del resultado del pesaje + / -),

- vista previa de los pesajes realizados en el terminal de pesaje en forma de tabla de pesaje,

- módulo de informes simplificado que le permite generar un informe,

- creación de plantillas de etiquetas desde el terminal de pesaje

- identificación de mercancías mediante el código EAN-13 y EAN-128,

- búsqueda rápida de productos mediante un escáner de código de barras,

- disponibilidad de bases de datos:operadores, productos, clientes, almacenes, taras (embalajes) etc.

Tipos de terminales:

-

PUE 5.15R, PUE 5.19R - tecnología de pantalla táctil resistiva. Clase de protección IP 66. Alta resistencia a la humedad y al polvo. En comparación con los modelos restantes, calidad limitada y menor resistencia a los golpes y arañazos. Posibilidad de uso con guantes que eviten arañazos (látex, material).

-

PUE 5.15IR, PUE 5.19IR - panel táctil en tecnología de infrarrojos. Grado de protección IP 66/67. Muy alto nivel de brillo y legibilidad de la pantalla. Alta resistencia a la humedad y al polvo. Muy buena resistencia mecánica, la capacidad de utilizar una mano enguantada (látex, tela o incluso cota de malla).

- PUE 5.15C, PUE 5.19C - tecnología capacitiva de la pantalla táctil. Clase de protección IP 66/67/69. Alto brillo y nivel de legibilidad. Alta resistencia a la humedad y al polvo, buena resistencia mecánica. Precisión absoluta de la detección táctil, detectando múltiples puntos de contacto (multi-touch).

Learn about the use and maintenance of stainless steel products:

Stainless Steel in RADWAG products. Standard and special applications

Extra payment

Extra payment

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Deutsch

Deutsch English

English Français

Français Italiano

Italiano Polski

Polski Türkiye

Türkiye Česky

Česky Português (Brasil)

Português (Brasil) USA

USA 中文

中文