DWT/RC HY Checkweigher

The DWT/RC Checkweigher is to control heavy loads or cumulative products in accordance with the requirements of the recipient or current regulation on Control of Packaged Goods. The device provides full control of goods moving in a process line. It can operate in dynamic or static mode. The checkweigher has been designed to operate in very harsh industrial conditions, as evidenced by the material it is made of (corrosion-resistant stainless steel) and its high IP protection rating (66/67).

Terminal: Easy Communication, Simple Operation

The DWT/RC Checkweigher is equipped with a user-friendly terminal that enables it to interact with external equipment. It also provides a range of information and control signals to facilitate integration into the production line. The terminal has a full alphanumeric keypad and a touchscreen display, which makes comfortable operation of the unit as simple as possible.

Checkweigher – Where Is It Indispensable? DWT/RC Application Areas

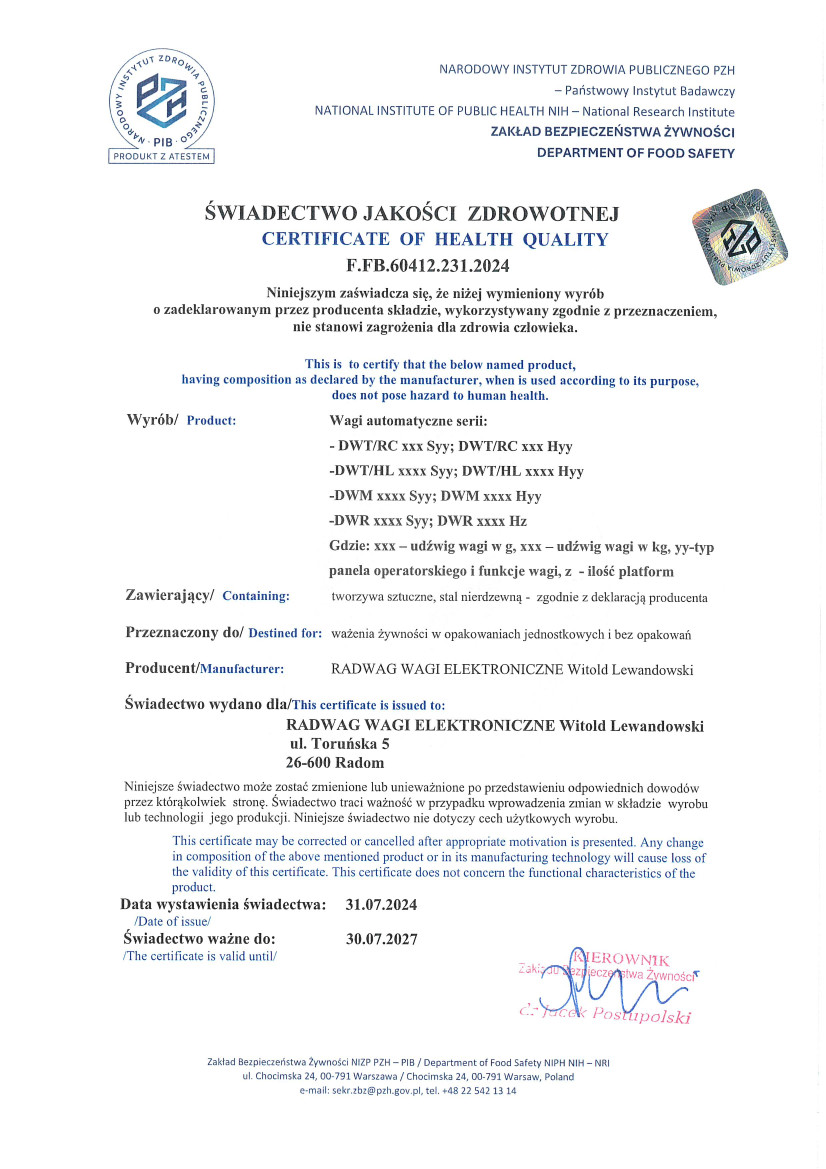

The checkweigher is approved for foodstuffs by the National Institute of Hygiene, so its main use is considered to be in the agri-food industry. However, this is not the only area of application for this instrument; its parameters and functions make it ideal for use in the meat, chemical, engineering, transport and shipping, tobacco, brewing, distilling and many other sectors.

DWT/RC Checkweigher – Key Functions

The device meets the current regulation of the Control of Packaged Goods. Since it is the customer who decides which functionalities will be implemented in his checkweigher, the device allows control according to the internal criteria of the specific company. The device has a database of products and operators, as well as real-time statistics and automatically generated reports compatible with the weighing mode. The DWT/RC Checkweigher allows the acquiring data on controlled goods and static weighing mode. In addition, it allows cooperation with other devices in the process line and with computer systems, as well as remote control.

Easy Cooperation with Additional Devices

The DWT/RC Checkweigher has been adapted for cooperation with processing line equipment and additional devices, which are optional accessories. The I/O system used in the checkweigher makes it configurable in many ways and can be fully integrated into an existing production line.

The DWT/RC Checkweigher compatibility brings you a range of new possibilities:

– Of archiving weighings on your computer

– Of printing on thermal printers

– Of operating additional conveyors,

– Of cooperating with dosing device with feedback.

Choose Your Checkweigher Version!

Depending on the requirements of your specific production line, the DWT/RC Checkweigher may have:

- Feeding conveyor with function of separating packages

- Discrimination of defective goods by weight

- Separate discriminating set for “too light” and “too heavy” goods

- Sounder and/or warning tower lights

- Software for keeping records from weighing processes

and operate:

- Dosing device with feedback

- Printer.

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文