Gehäuse

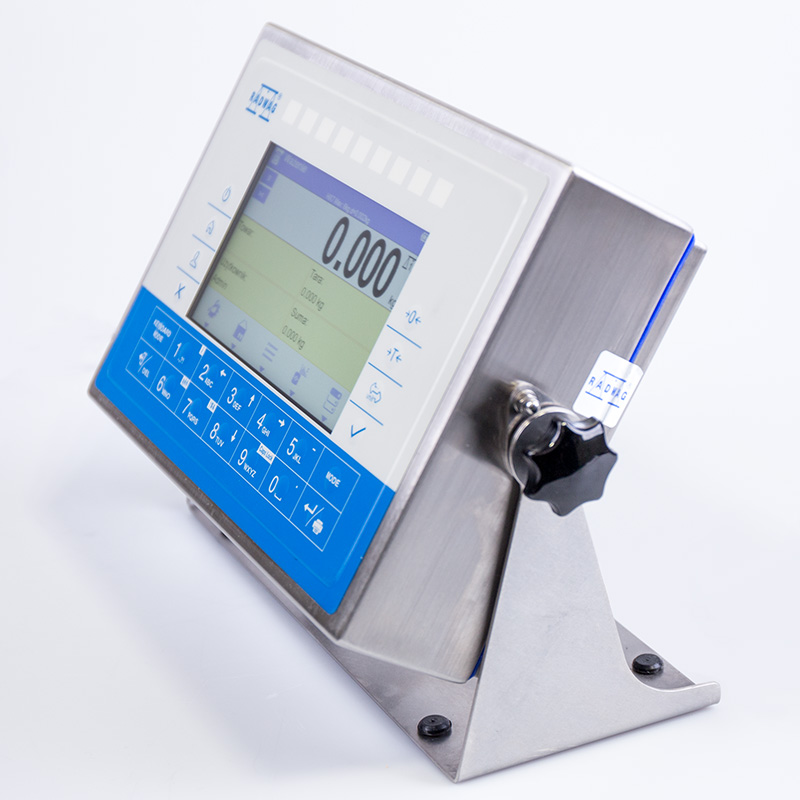

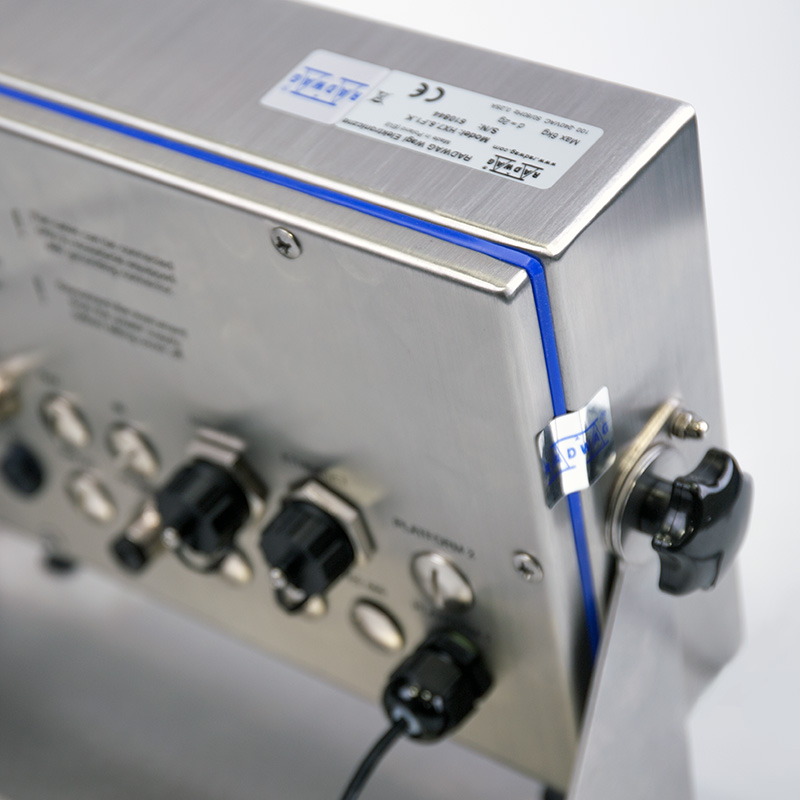

Das Gehäuse aus Edelstahl AISI 304 gewährleistet einen hohen Schutz gegen Eindringen, IP66 / IP68. Die Anzeige verfügt über ein 7" Farb-LCD-Display und eine Folientastatur. Die einfache Bedienung, das übersichtliche Menü und die intuitive Anordnung der Informationen auf dem Display garantieren einen hohen Bedienungskomfort. Hermetische Schnittstellenanschlüsse befinden sich auf der Rückseite des Gehäuses. Die stabile Montagehalterung ermöglicht die Montage der Anzeige entweder auf einer beliebigen ebenen horizontalen Fläche oder an der Wand, wo der Neigungswinkel leicht eingestellt werden kann.

Die Basisversion des Terminal unterstützt 1 analoge Wägeplattform. Die Möglichkeit, ein zusätzliches Wägemodul zu installieren, ermöglicht die Unterstützung von 2 Wägeplattformen.

Die Messgerät-Software ermöglicht die Durchführung von Prozessen wie Wiegen, Zählen der Teile, Dosieren, Etikettieren, Formulierungen und prozentuales Wägen. Das Informationssystem von Messgerät basiert auf Datenbanken (wie z.B.: Benutzer, Produkte, Wägungen, Verpackungen, Rezepturen, Kunden) und ALIBI-Speicher, der die Sicherheit der gespeicherten Daten garantiert.

Bei der Erstellung der Software wurde großer Wert auf ihre Funktionalität und Ergonomie gelegt. Dies führte zu einem erhöhten Komfort bei der Bedienung des Messgeräts.

Optionale Stromversorgung über interne Batterie

Mit der optionalen Batterie kann die PUE HX7 in einer instabilen oder völlig instabilen Netzversorgung betrieben werden. Dies wirkt sich positiv auf die Sicherheit der gesammelten Daten aus und erhöht den Arbeitskomfort.

Kommunikationsschnittstellen

Das Anzeigegerät ist mit RS 322, RS 485, USB, Ethernet, digitalen Eingängen/Ausgängen und analogem Ausgang ausgestattet. Dies ermöglicht die Zusammenarbeit mit externen Geräten: Barcode-Scanner, Drucker, externe Anzeigen, Bedientasten, Lichtsignalsäulen, andere Steuer-/Signalgeräte, Systeme zur automatischen Prozesssteuerung und übergeordnete IT-Systeme. Dies ist aufgrund des implementierten und komplexen zeichenbasierten Kommunikationsprotokolls möglich. In Zukunft werden die Schnittstellen mit Profibus und Profinet erweitert. Zusätzlich werden die Protokolle Modbus RTU und TCP implementiert.

Erfahren Sie mehr über die Verwendung und Pflege von Edelstahlprodukten:

Rostfreier Stahl in RADWAG-Produkten. Standard- und Spezialanwendungen

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) English

English Español

Español Français

Français Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文