RB 2.5Y.F Roboter-Wägesystem

Das Klima- und Befeuchtungssystem garantiert konstante klimatische Bedingungen in der Kammer, was eine ordnungsgemäße Filterkonditionierung gewährleistet.

Die Überwachung der Umgebungsbedingungen kontrolliert die aktuellen Bedingungen in der Kammer und ermöglicht diese Daten zu speichern und zu melden.

Hauptvorteile:

- Vollautomatisches Wiegesystem von Filtern mit dem Durchmesser von Ø 47 mm

- Konformität mit der Norm EN 12341:2014

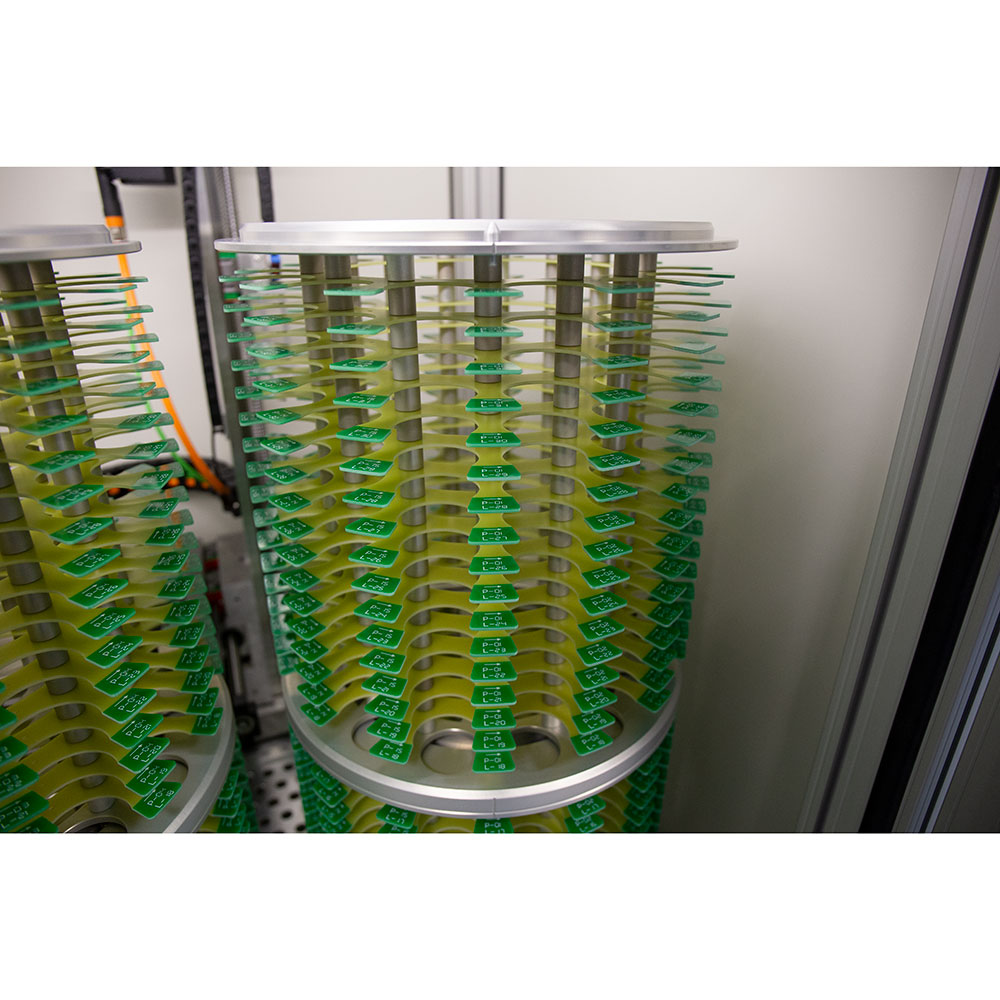

- Möglichkeit der Überprüfung zu 1020 Filter

- Zusätzliches Referenzmagazin

- Zeitersparnis im Vergleich zum manuellen Wiegen von Filtern

- Eliminierung des menschlichen Faktors als Grund für das Auftreten von Messfehlern

- Verwaltung des Processus dank der Software RMCS Filter

- Automatische Datenaufzeichnung, die Möglichkeit Berichte und Statistiken zu erstellen

- Kodierung und Identifikation von Filtern dank dem QR-Code-System

- Eliminierung des Einflusses der Elektrostatik auf die Messung

- Dichtheit der Roboterkammer und der Wiegekammer von Filtern

- Klimaanlage, HEPA-Filter (Ausführung ohne Klimaanlage auf Anfrage)

- zwei Magazine für Speicherung von Filtern vor und nach dem Wiegen. Einer von ihnen wird während des Filterwägens verwendet, der andere ist das Magazin zur Konditionierung. Jedes besteht aus 35 Scheiben mit 15 Filterpositionen.

- Referenzmagazin mit sechs Positionen zur Aufbewahrung von Prüfgewichten und Referenzfiltern.

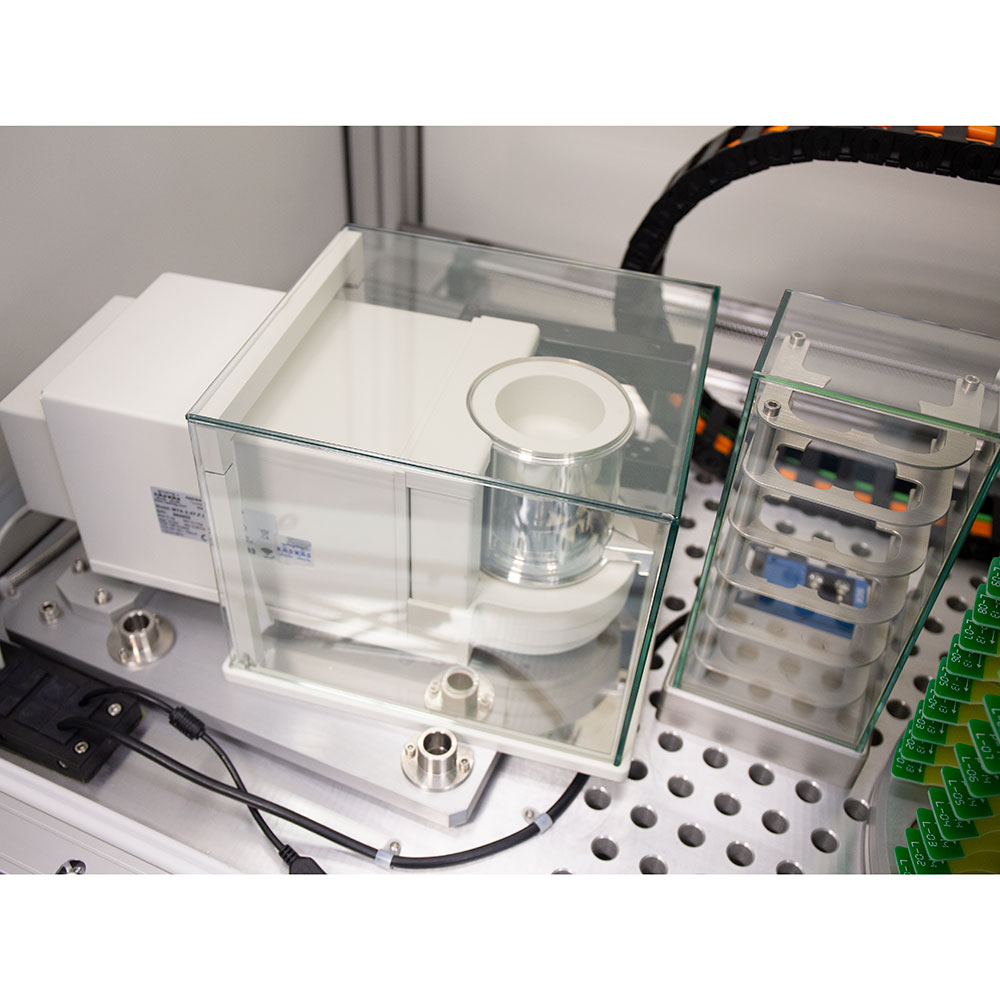

- Roboter mit einem Greifer, der den Transport von Filtern zwischen dem Magazin und Mikrowaage ermöglicht. Es bewegt sich in drei Achsen X, Y, Z.

- Mikrowaage mit einem Windschutz

- Ionisationssystem

- Klimaanlage reinigt zusammen mit dem HEPA-Filter die Luft, die aus der Umgebung in die Roboterkammer gelangt

- Überwachung der Umgebungsbedingungen, vor allem der Temperatur, der Luftfeuchtigkeit und des Drucks

- Messgerät verwaltet den Betrieb des Geräts

- Barcode-Scanner QR im Gerät eingebaut

- Drucker von QR-Coden

- Computer PC mit der RMCS Filter-Software, der den Betrieb des gesamten Geräts verwaltet

- Steuerungs- und Regelsysteme

- Außen Aggregat des Klimaanlages

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) English

English Español

Español Français

Français Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文