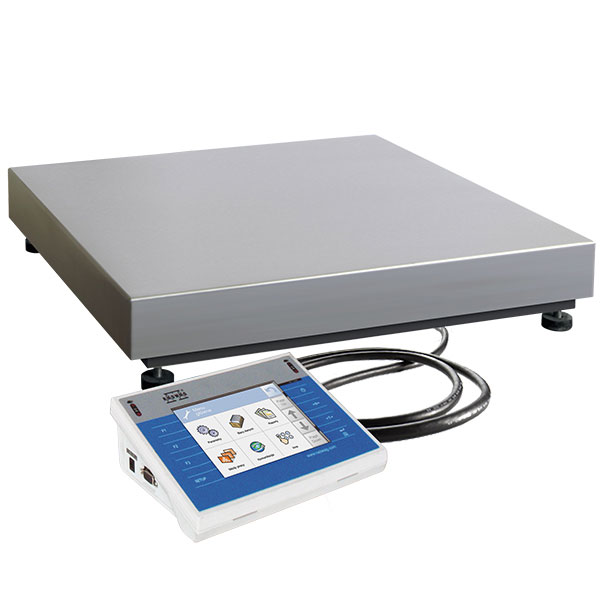

Multifunktionswaage WPY 150/C3/K

unter industriellen Bedingungen und unter Verwendung eines modernen Terminals der Serie PUE7 bestimmt.

Anwendung

Serie WPY

Design und Funktionalität

- Programmierung des Displays und der Funktionstasten

- Programmierung der Infrarot-Näherungssensoren

- Gestaltung von Ausdrucken

- Gestaltung von Textdaten, die auf dem Terminaldisplay angezeigt werden

Software Funktionalität:

- Verfügbare Arbeitsmodi: Wägen, Stückzählung, Prozenteinstellung, Rezeptur, Dichtebestimmung, Tierwägung

- Generierung von Standardetiketten für die Zuordnung von Einzelwaren

- Erzeugung von Etiketten für die Zuordnung von Sammelbehältern

- Generierung von Etiketten für den Abgleich von Behältern mit Sammelbehältern

-

drei Möglichkeiten, einen Etikettendruck auszulösen:

- manuell

- durch Zählerstand

- durch den eingestellten Massenwert eines Produkts - Kontrollwaagenmodus (+/- Kontrolle des Messergebnisses)

- Produktidentifikation über EAN-13- und EAN-128-Codes

- Zugang zu Datenbanken mit Bedienern, Produkten, Rohstoffen, Kunden, Wägeprotokollen, universellen Variablen und Taras.

Erfahren Sie mehr über die Verwendung und Pflege von Edelstahlprodukten:

Rostfreier Stahl in RADWAG-Produkten. Standard- und Spezialanwendungen

Extra payment

Extra payment

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin English

English Español

Español Français

Français Italiano

Italiano Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文