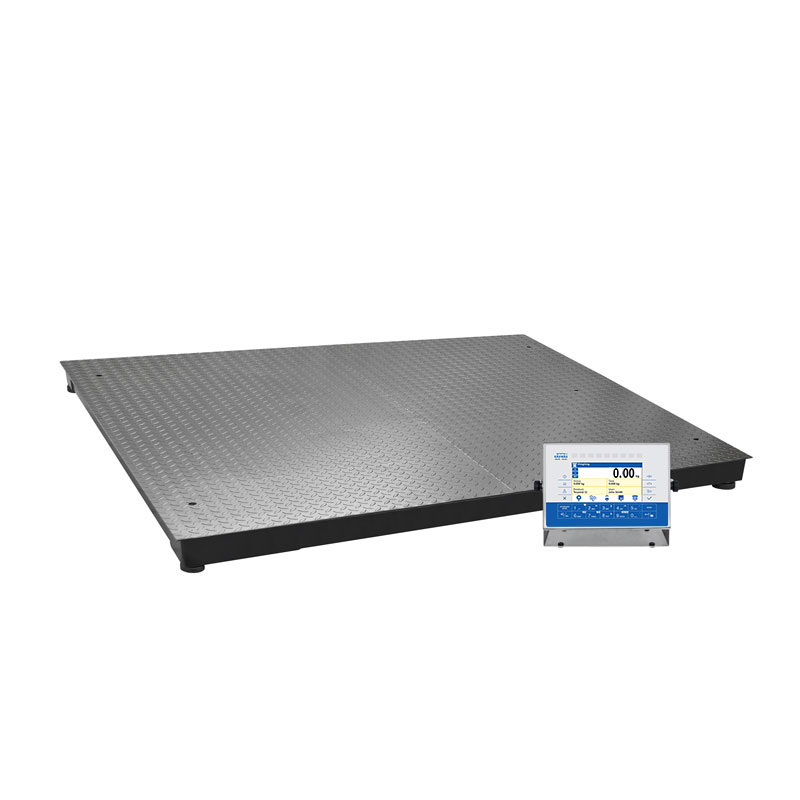

Multifunktions- Plattformwaage HX7.4.6000.C11

Wägeterminal PUE HX7

Die Waage HX7.4 C kann dank dieser Steckverbindungen mit vielen externen:

- Geräten funktionieren,

- unter anderem Druckern,

- Barcode-Scannern,

- Datenbanksoftware,

- SPS-Steuerungen,

- Geräte für die industrielle Automatisierung.

Eine spezielle, stabile Halterung erlaubt die Montage des Wägeterminal auf ebenen waagerechten oder senkrechten Flächen. Es ist möglich, den Neigungswinkel nach den Bedürfnissen einzustellen.

Datenbanken

- Benutzer,

- Produkte,

- Wägungen,

- Verpackungen,

- Rezepturen,

- Kunden

- ALIBI-Speicher. Die Sicherheit der gespeicherten Daten wird durch den ALIBI-Speicher garantiert.

Erfahren Sie mehr über die Verwendung und Pflege von Edelstahlprodukten:

Rostfreier Stahl in RADWAG-Produkten. Standard- und Spezialanwendungen

Additional fee

Additional fee

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) English

English Español

Español Français

Français Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文