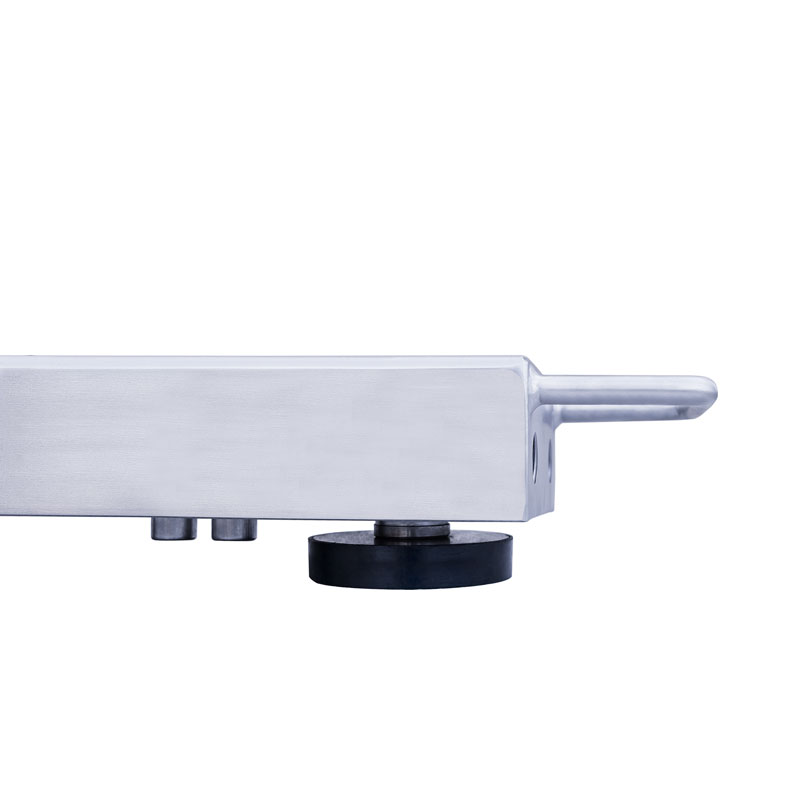

Die Waage wird aus Edelstahl gefertigt. Die Waage ist mit dem PUE H315-Wägeterminal mit einem LCD-Display ausgestattet.

Das Verbindungskabel zwischen dem Wägeterminal und der Plattform hat eine Länge von 3 m.

Auf Anfrage können Waagen auch mit zwei Messbereichen geliefert werden.

Erfahren Sie mehr über die Verwendung und Pflege von Edelstahlprodukten:

Rostfreier Stahl in RADWAG-Produkten. Standard- und Spezialanwendungen

Extra payment

Extra payment

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin English

English Español

Español Français

Français Italiano

Italiano Polski

Polski Türkiye

Türkiye Česky

Česky Português (Brasil)

Português (Brasil) USA

USA 中文

中文