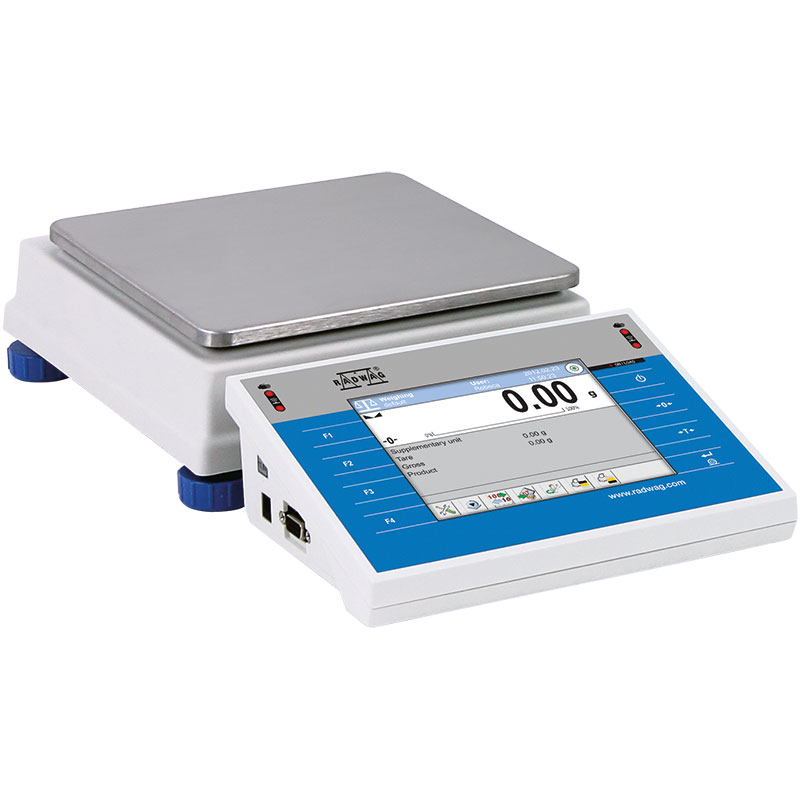

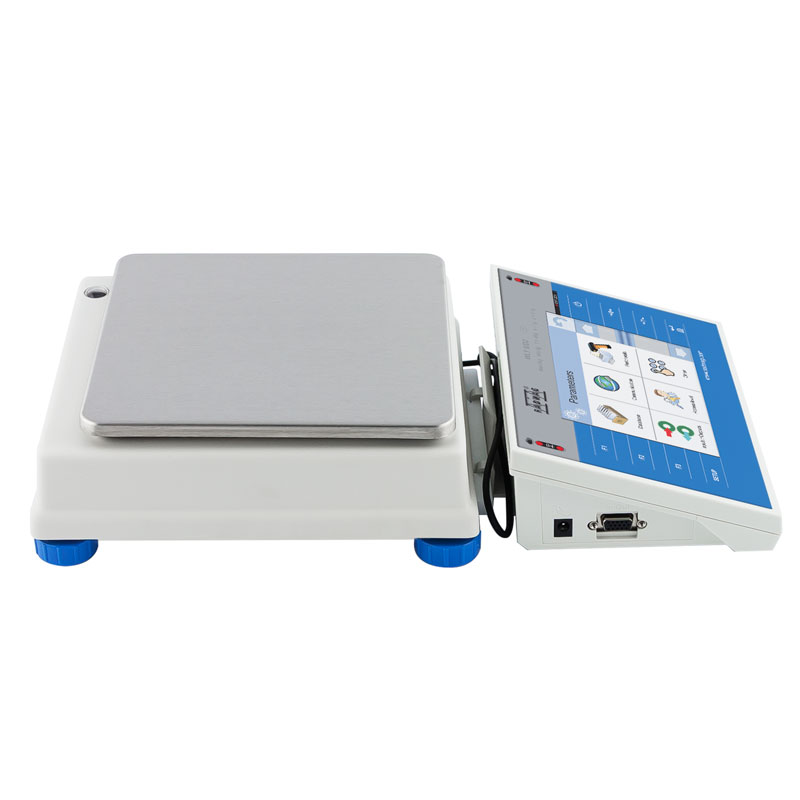

WLY 6/D2 上皿天秤

Not just weighing

Use the potential

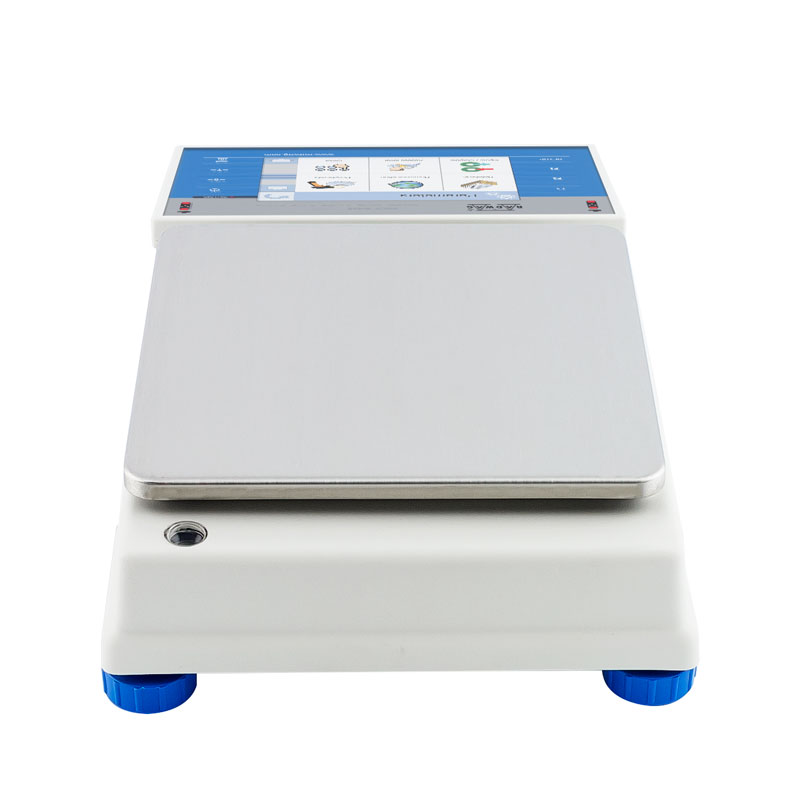

The Workflow Module

DIY with WLY

- You will program on-screen keys and functional keys

- You will program infrared proximity sensors

- You will design printouts

- You will design text data that is displayed in an indicator display.

Want to generate labels?

- Standard labels for single products

- C labels for cumulative containers

- CC labels for containers with cumulative containers.

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch English

English Español

Español Français

Français Italiano

Italiano Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文