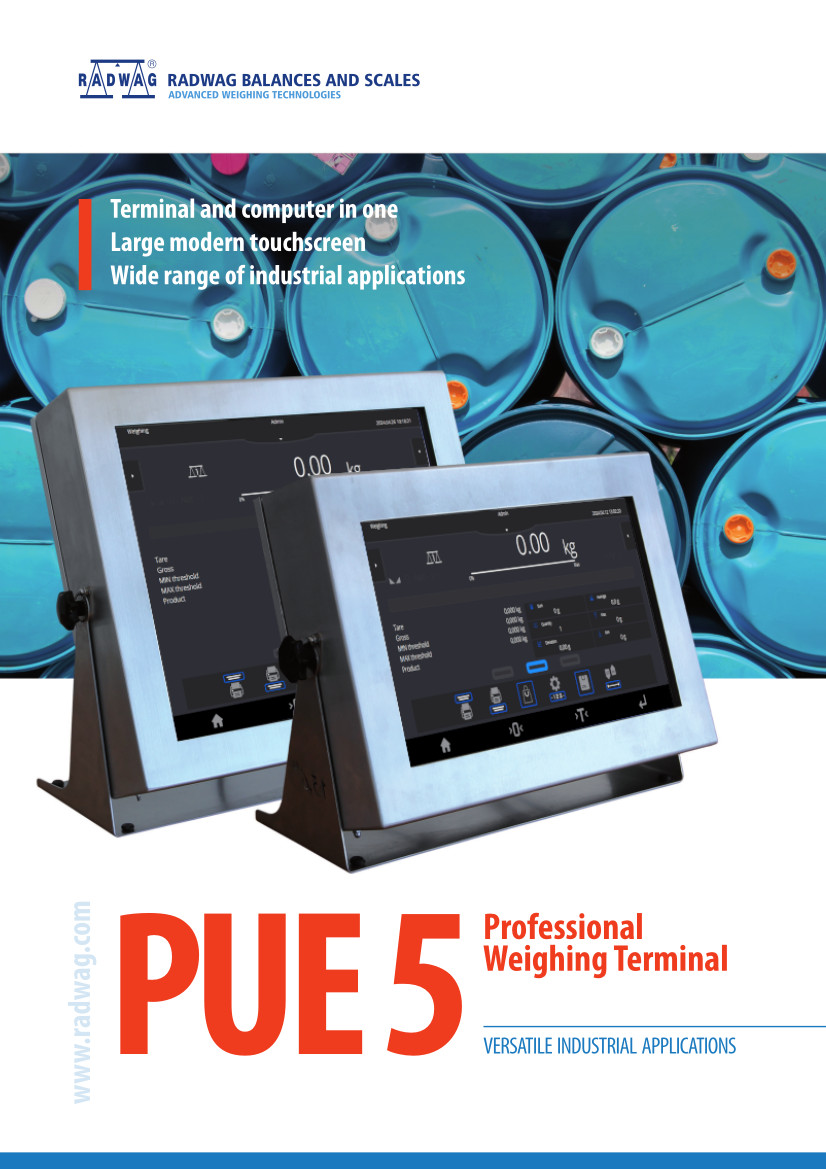

Il terminale viene fornit equipaggiato con le seguenti intrfacce: 2 × RS232, 1 × RS485, 1 x Ethernet, 4 x USB 2.0.

I terminali serie PUE 5 possono essere connessi a tre basamenti supplementari permettendo la gestione di fino a 4 basamenti in totale.

Utilizzo suggerito:

I terminali serie PUE 5 sono sistemi di pesatura multifunzionali. Combinano le migliiori prstazioni di un PC ad un sistema di pesatura. iPUE 5 operano sulla base della piattaforma OS Windows, permettendo di creare le migliori configurazioni dei sistemi lle necessita degli utilizzatri mediante l’installazione delle relative applicazioni.

Se accoppiato ad un sistema di dosaggio o di formulazione il PUE 5 permette operazioni con diversi basamenti ed il dosaggio simultaneo per un controllo completo del processo. Un sistema di dosaggio o di formulazione basato sull’utilizzo di un terminale serie PUE 5 non richiede l’utiilzzo di un PC addizionale. La compilazione del database e possibile sia attraverso l’utilizzo dello schermo touch screen del PUE 5 o utilizzando una normale tastiera PC connessa al terminale.

Campi di utilizzo:

- Le applicazioni principali dei terminali seri PUE 5:

- Composizione di sistemi di pesatura industriali a cella di carico;

- Applicazioni di pesata multiple supervisionate da un PC tramite modulo Ethernet;

- Possibilta di connessione di basamenti multipli ai terminali industriali.

Learn about the use and maintenance of stainless steel products:

Stainless Steel in RADWAG products. Standard and special applications

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch English

English Español

Español Français

Français Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文