Bilancia di precisione PS 4500.X7.M.CPC

MONO

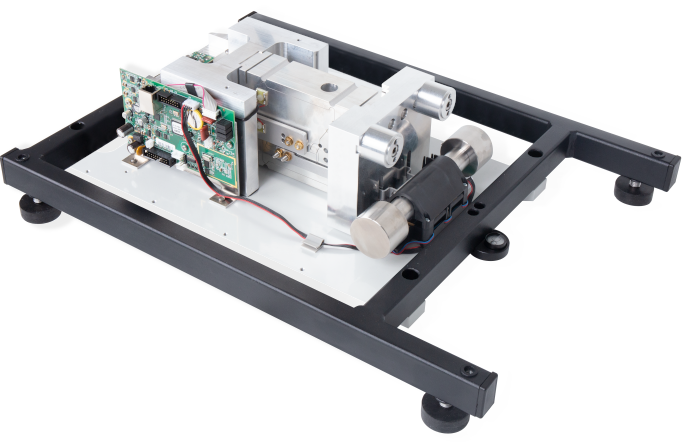

BLOCK. Il design innovativo delle bilance PS X7.M è caratterizzato da un nuovo attacco del piatto a punto singolo, che garantisce un'ottima geometria della bilancia e riduce al minimo l'eccentricità. Il design a labirinto assicura un'elevata resistenza alla contaminazione.

Modulo di pesatura

MONO

BLOCK consente di pesare carichi con una precisione di d=0,01 g con una capacità di carico fino a 10 kg. La base rigida assicura la stabilità del sistema di pesatura e un'elevata resistenza agli urti. Il sistema di regolazione interno garantisce precisione ed elevata ripetibilità delle misure. Il rapporto di massa del peso interno consente la valutazione su tutto il campo di misura.Caratteristiche principali della serie PS X7.M:

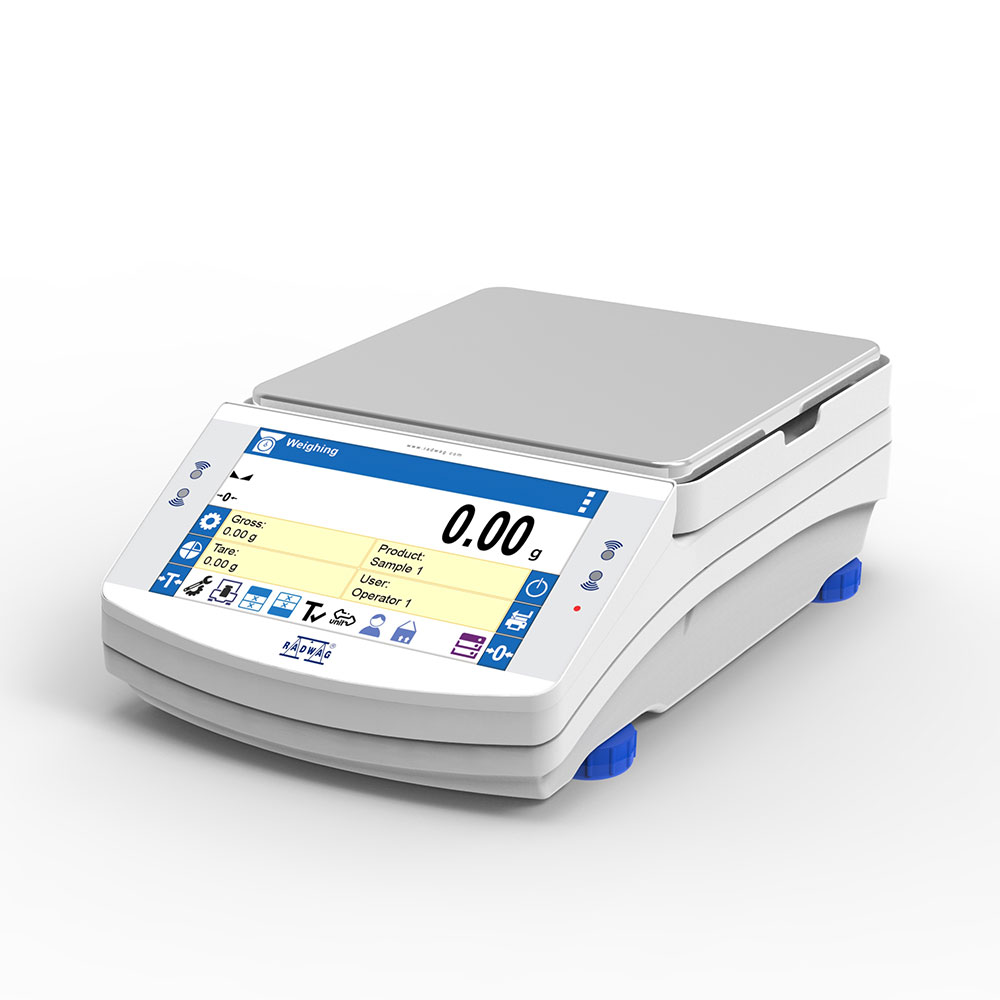

- precisione di d=0,01g con una capacità di carico fino a 10 kg,

- elevata resistenza ai fattori esterni,

- garanzia di stabilità e ripetibilità nel tempo,

-

utilizzo della tecnologia

MONO

BLOCK, - regolazione interna nell'intero campo di misura,

- ampi database e memoria ALIBI,

- pannello tattile ergonomico a colori da 7 pollici,

- funzionamento senza contatto.

Database

- Prodotti (5.000 prodotti)

- Utenti (100 utenti)

- Imballaggi (100 imballaggi)

- Clienti (1.000 clienti)

- Ricette (100 ricette)

- Rapporti delle ricette (500 rapporti)

- Condizioni ambientali (10.000 record)

- Pesate (50.000 record)

- Memoria Alibi (512.000 record)

- Rapporti di controllo (1.000 rapporti)

- Tare medie (1.000 rapporti).

Memoria ALIBI

Nuove possibilità

Learn about the use and maintenance of stainless steel products:

Stainless Steel in RADWAG products. Standard and special applications

Wi-Fi® is a registered trademark of Wi-Fi Alliance®.

Additional fee

Additional fee

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch English

English Español

Español Français

Français Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文