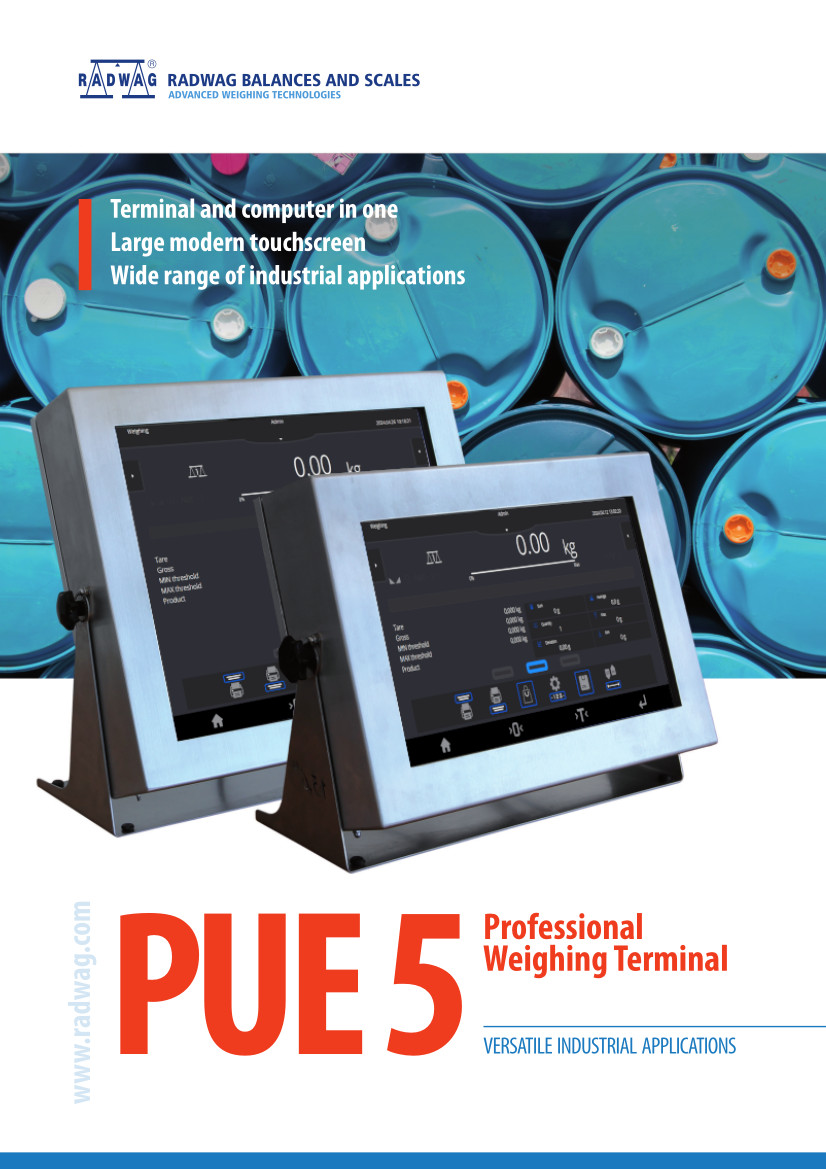

The terminals come standard with interfaces: 2 × RS232, 1 × RS485, 1 × Ethernet, 4 × USB 2.0.

PUE 5 series can be extended by additional 3 weighing modules for simultaneous operation of maximum 4 weighing platforms.

Optionally available PROFIBUS DP interface enables terminals cooperation with industrial ProfiBus network.

Intended Use:

The terminal PUE 5 series is a multifunctional weighing device. It combines the best features of a PC computer and a scale. The PUE 5 operates on basis of OS Windows, creating the best option for configuring the device to individual customer requirements through installing corresponding application.

If applied with dosing or formula making systems, the PUE 5 allows for operation with multiple weighing platforms, and simultaneous dosing with full process control. A dosing or formula making system that is configured on basis of the terminal PUE 5 series does not require an additional PC computer. Database editing is possible from the level of PUE 5 touch screen display or an optional PC keyboard.

Area of Use:

Main applications for terminal PUE 5 series:

- Designing industrial load cell scales;

- Multiple weighing applications supervised by a computer system through Ethernet module;

- Possibility of connecting large quantity of additional weighing platforms to industrial terminals.

Learn about the use and maintenance of stainless steel products:

Stainless Steel in RADWAG products. Standard and special applications

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch English

English Español

Español Français

Français Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky 中文

中文