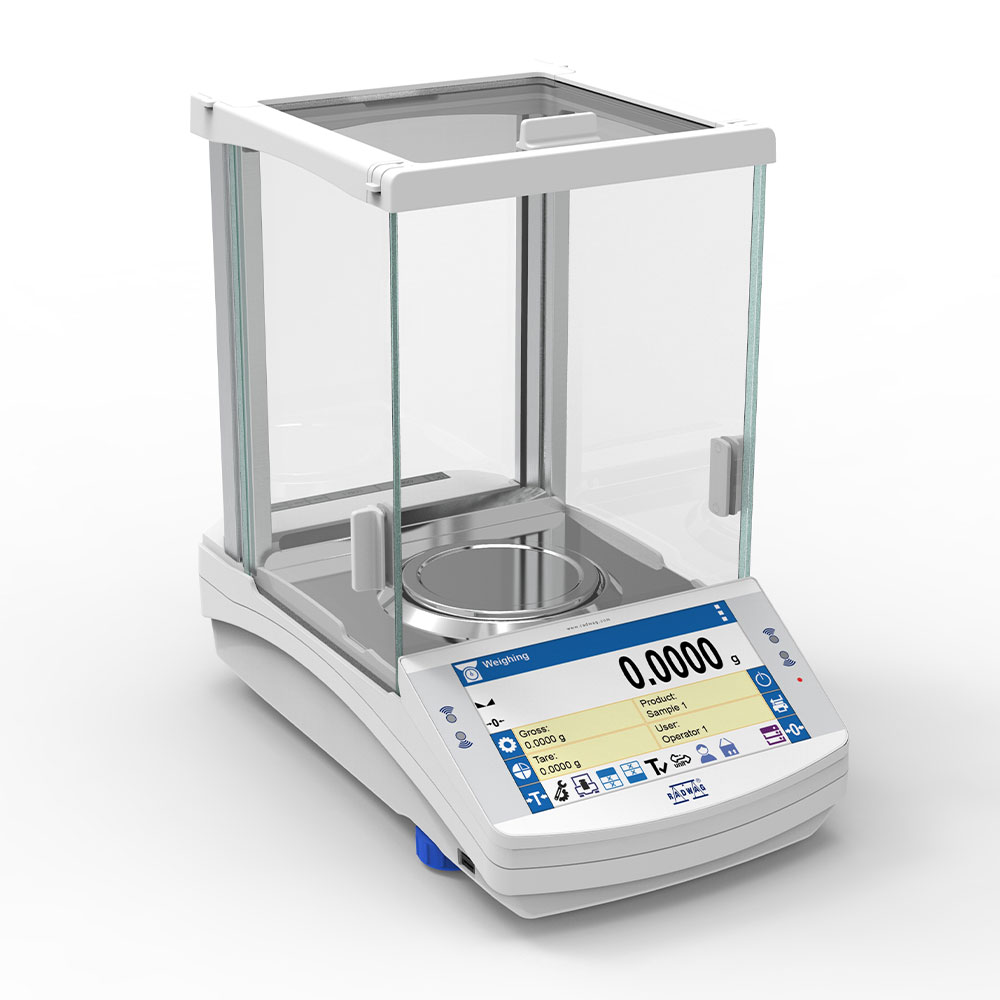

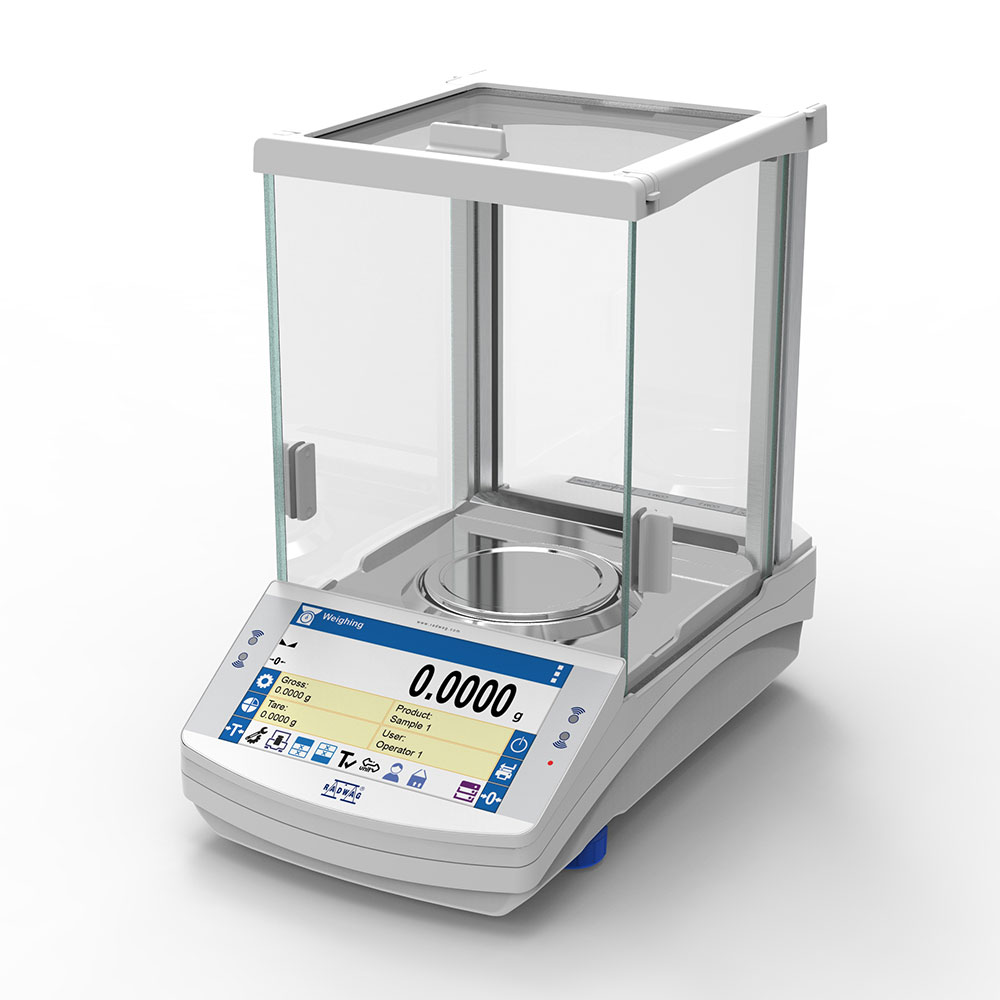

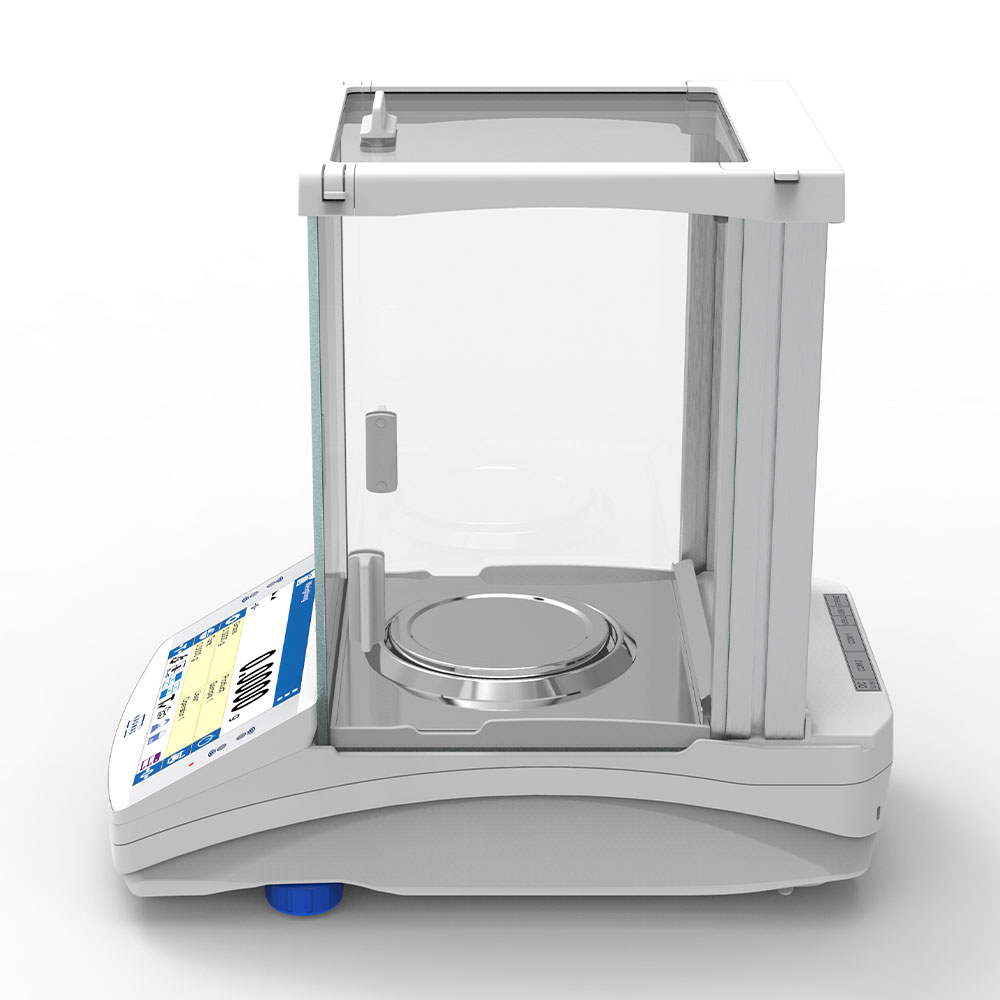

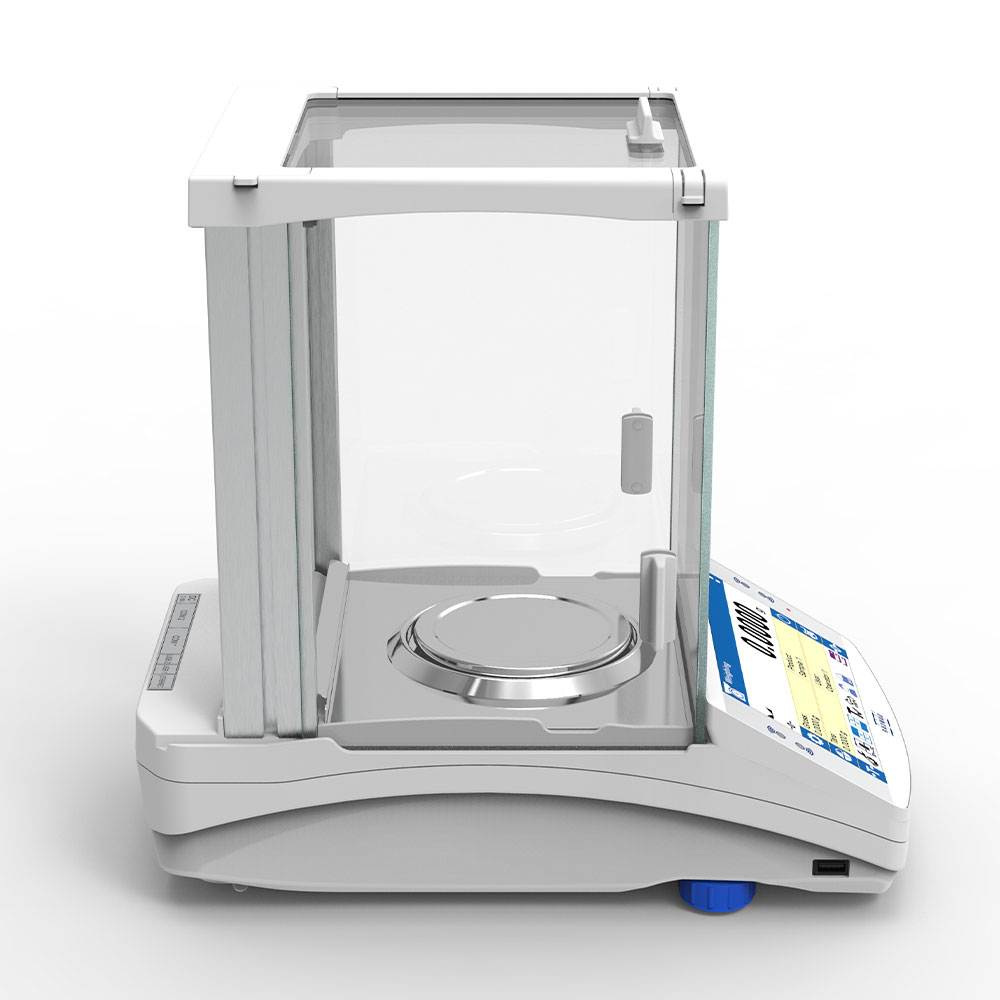

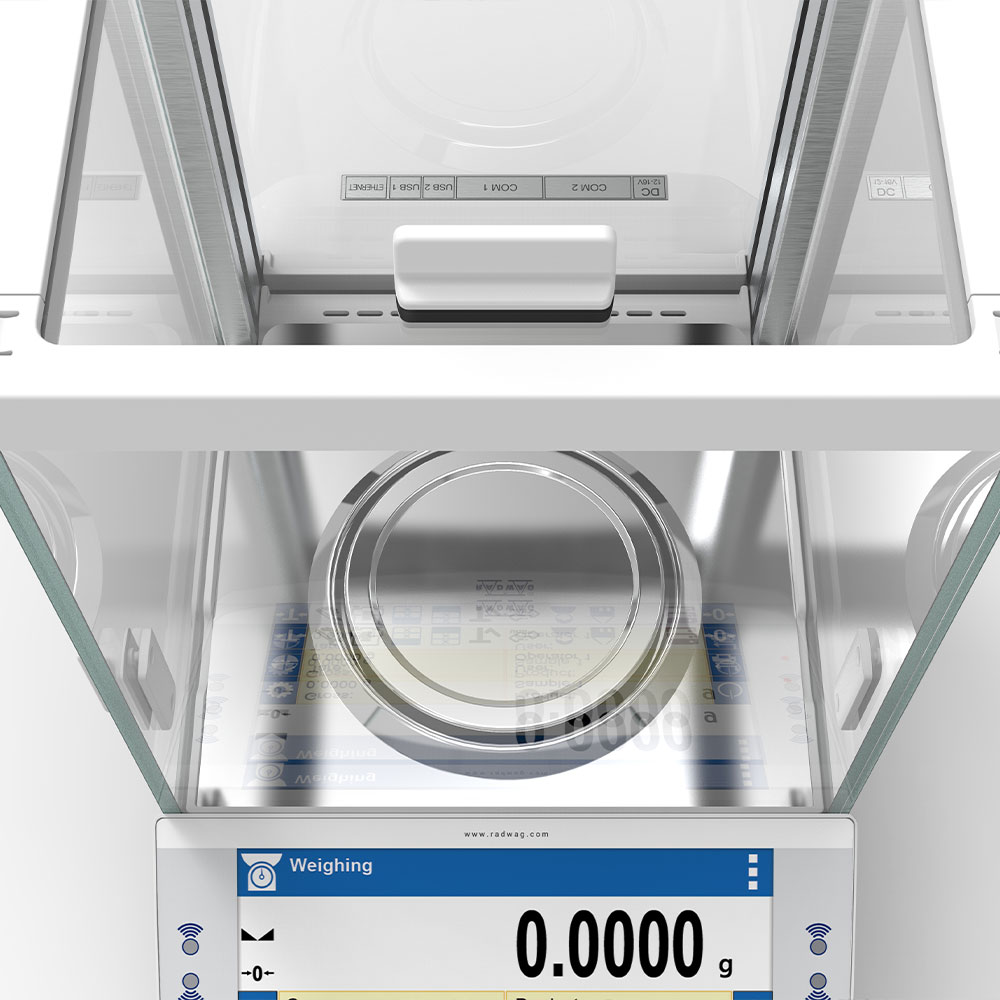

AS 520.X7 Analytical Balance

Ergonomic Mechanical

Design

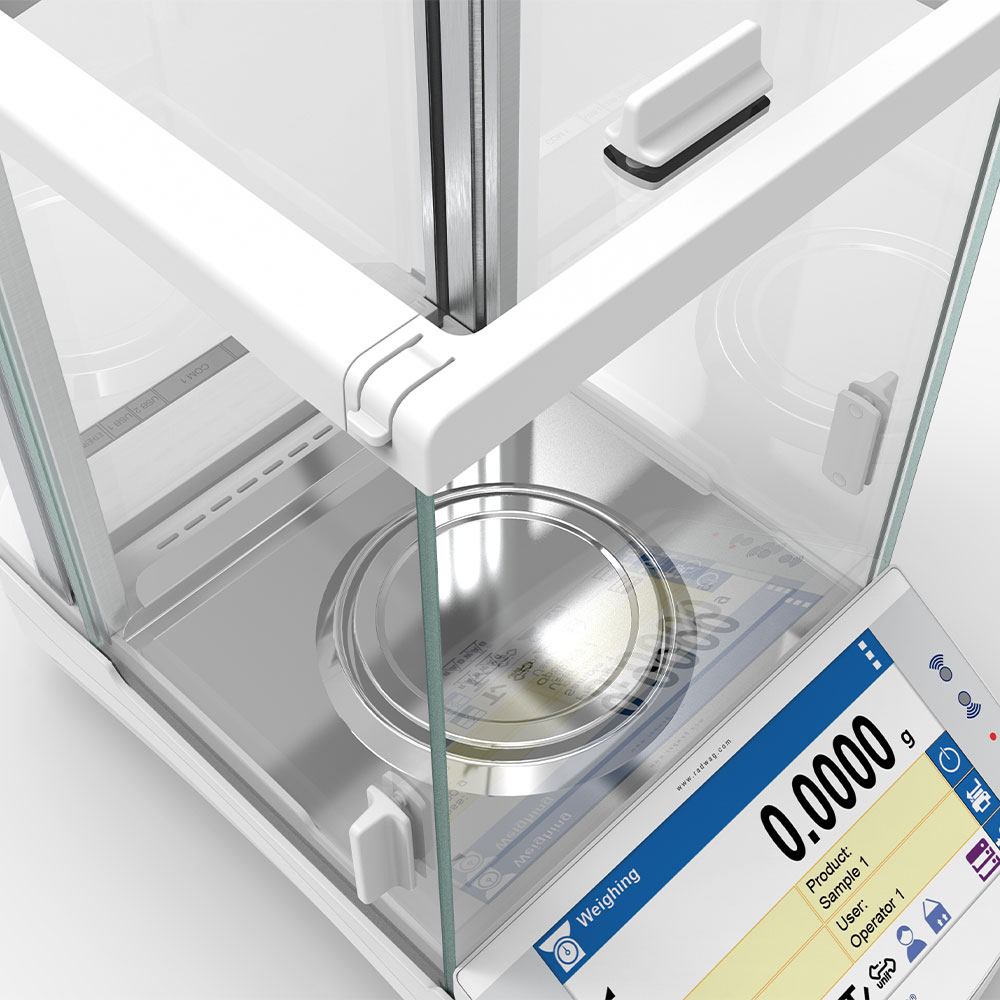

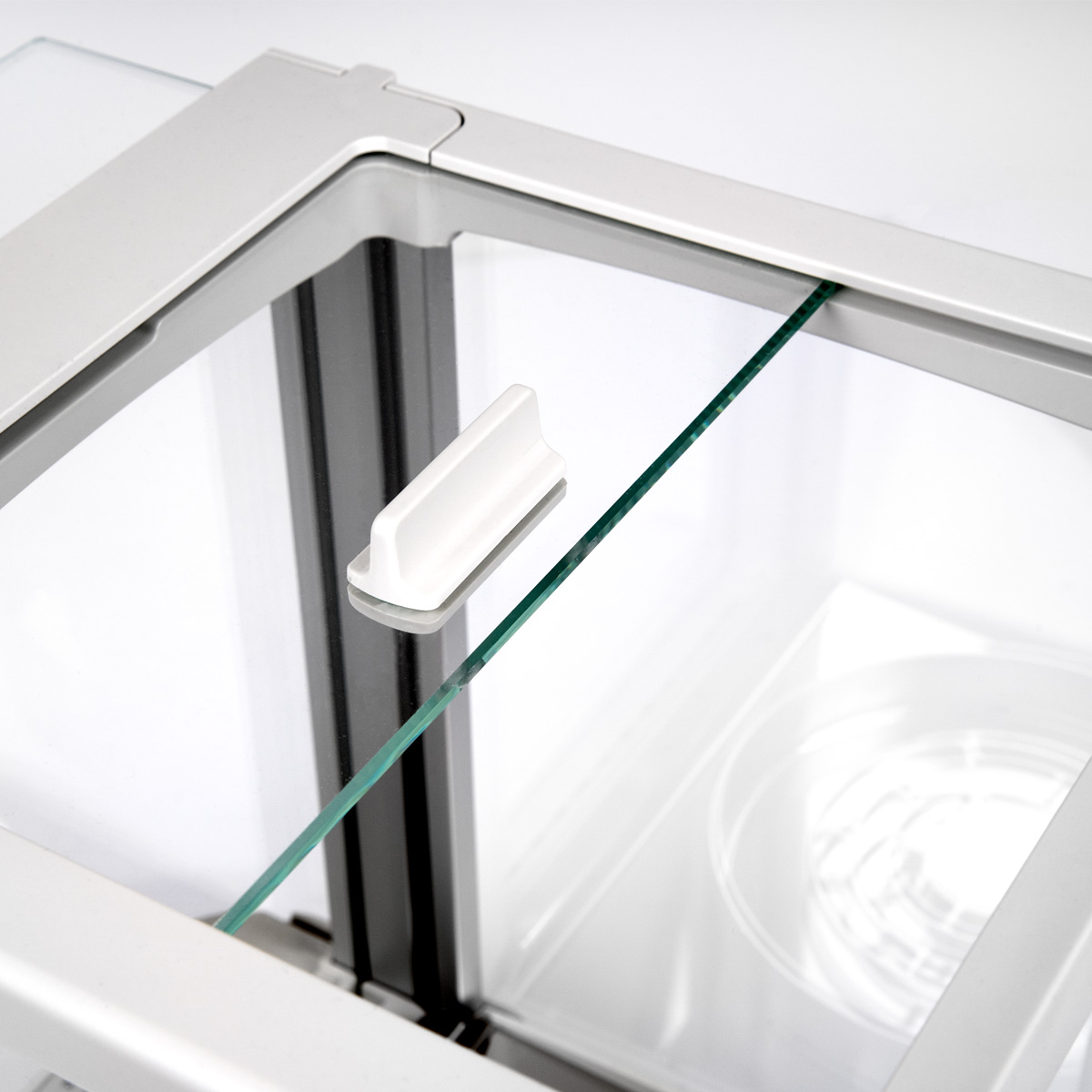

Dual-CLICK system allows tool-free assembly and disassembly of the weighing chamber, and a special design of guides for weighing chamber panes (no rims) makes keeping the device clean convenient.

Innovative construction solutions increase balance durability and reliability in long-term operation.

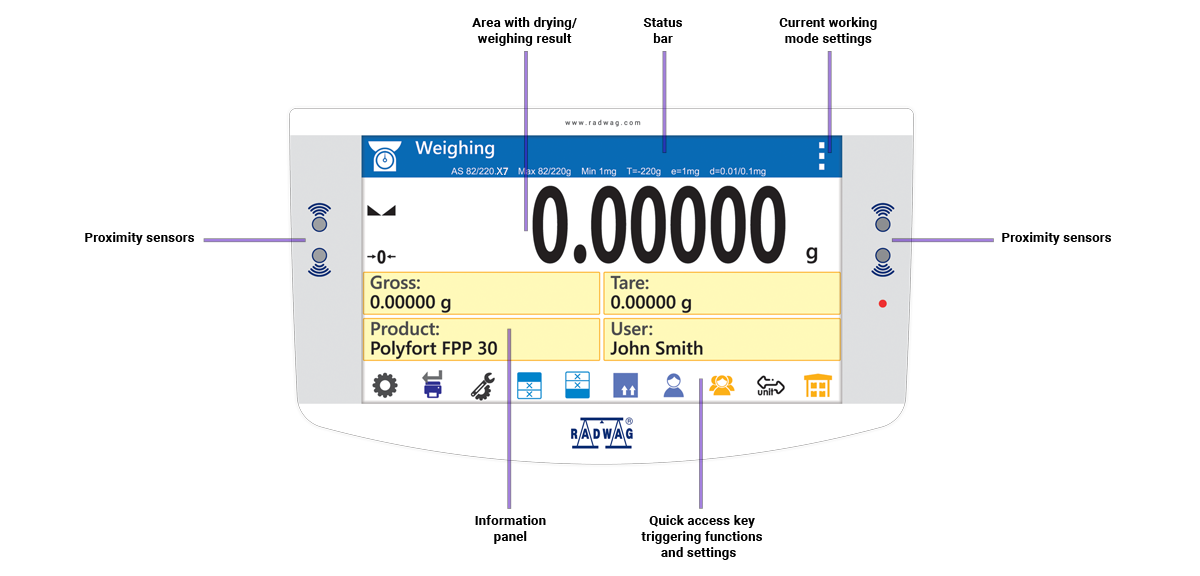

Colour Touch Screen

Personalization provides access to necessary information and work results directly from the main display panel. The user can fully configure sets of buttons and link them to a specific operation mode, and define information and text fields.

LevelSENSING System

Internal Adjustment

Modernized internal adjustment system guarantees accurate indications in extremely unfavourable conditions.

SMARTLab

Sensors

Touch-free operation and programmable sensors facilitate daily work and reduce the range of actions performed during the weighing procedure.

Alibi memory

Data safety is assured with the ALIBI memory, which is integrated into AS X7 balances. The memory enables record of up to 500 000 weighings and guarantees continuity of data collection over a long period of time.

Wi-Fi®

Wi-Fi®Remote control of the balance via devices, operation of which is based on Android, IPhone, Windows10 systems.

Accessing information in the balance depends on the user's permission level. The administrator can manage three different permission levels.

Automatic Weighing Records

Reports on processes and partial weighings can be generated and sent for archiving via the USB to external devices.

Ambient Conditions Monitoring

Communication with RADWAG thermo-hygro-barometer allows monitoring of ambient conditions such as temperature and atmospheric humidity.

Databases

Weighing data is recorded in 9 databases:

• Products (5 000 products)

• Users (100 users)

• Packaging (100 packaging types)

• Customers (1 000 customers)

• Formulations (100 formulations)

• Formulations reports (500 reports)

• Ambient Conditions (10 000 records)

• Weighings (50 000 records)

• ALIBI memory (512 000 records).

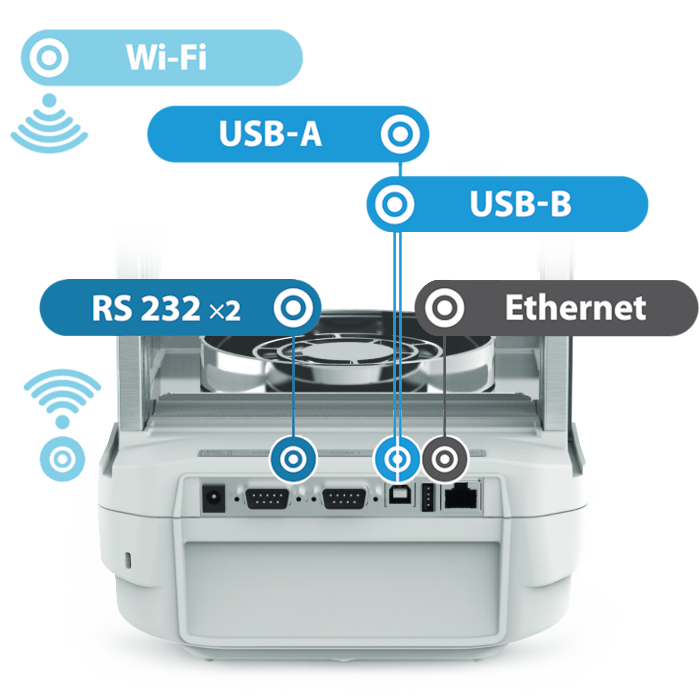

Communication Interfaces

AS X7 balances are equipped with Kensington Lock, which allows to secure the device against theft.

Learn about the use and maintenance of stainless steel products:

Stainless Steel in RADWAG products. Standard and special applications

Wi-Fi® is a registered trademark of Wi-Fi Alliance®.

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Português (Brasil)

Português (Brasil) Deutsch

Deutsch English

English Español

Español Français

Français Italiano

Italiano Japanese (日本語)

Japanese (日本語) Polski

Polski Türkiye

Türkiye Česky

Česky 中文

中文