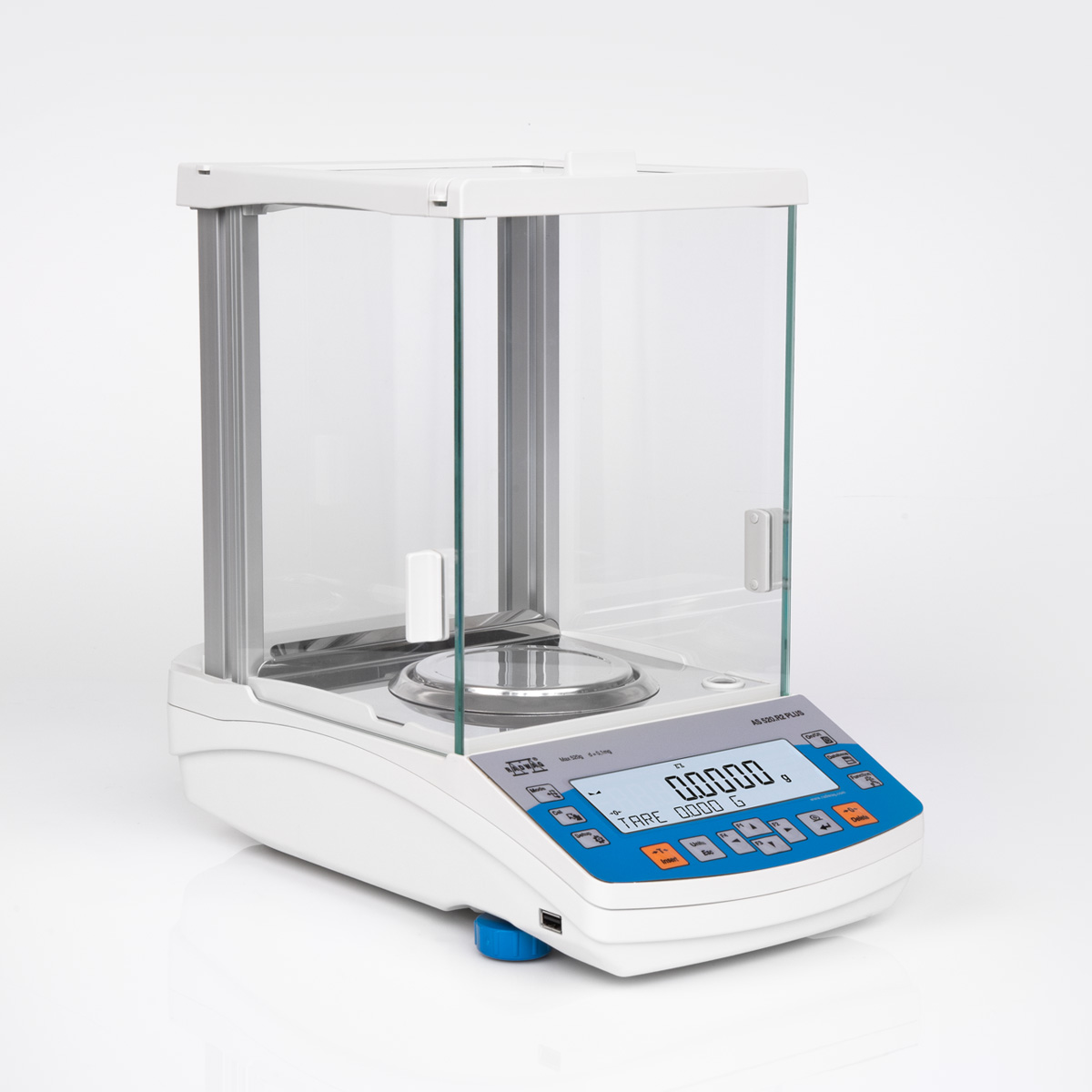

Balance analytique AS 310.R2 PLUS

Construction ergonomique

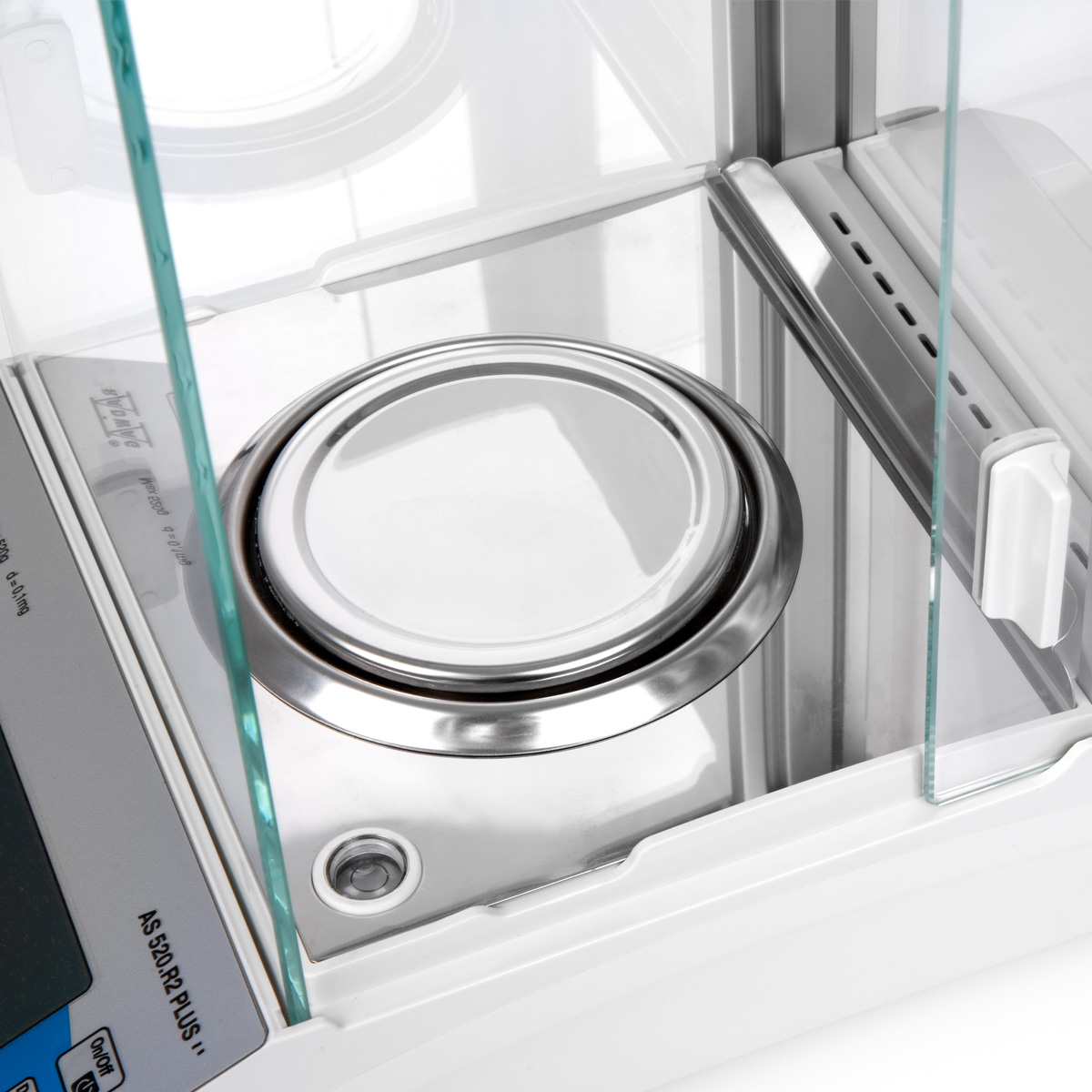

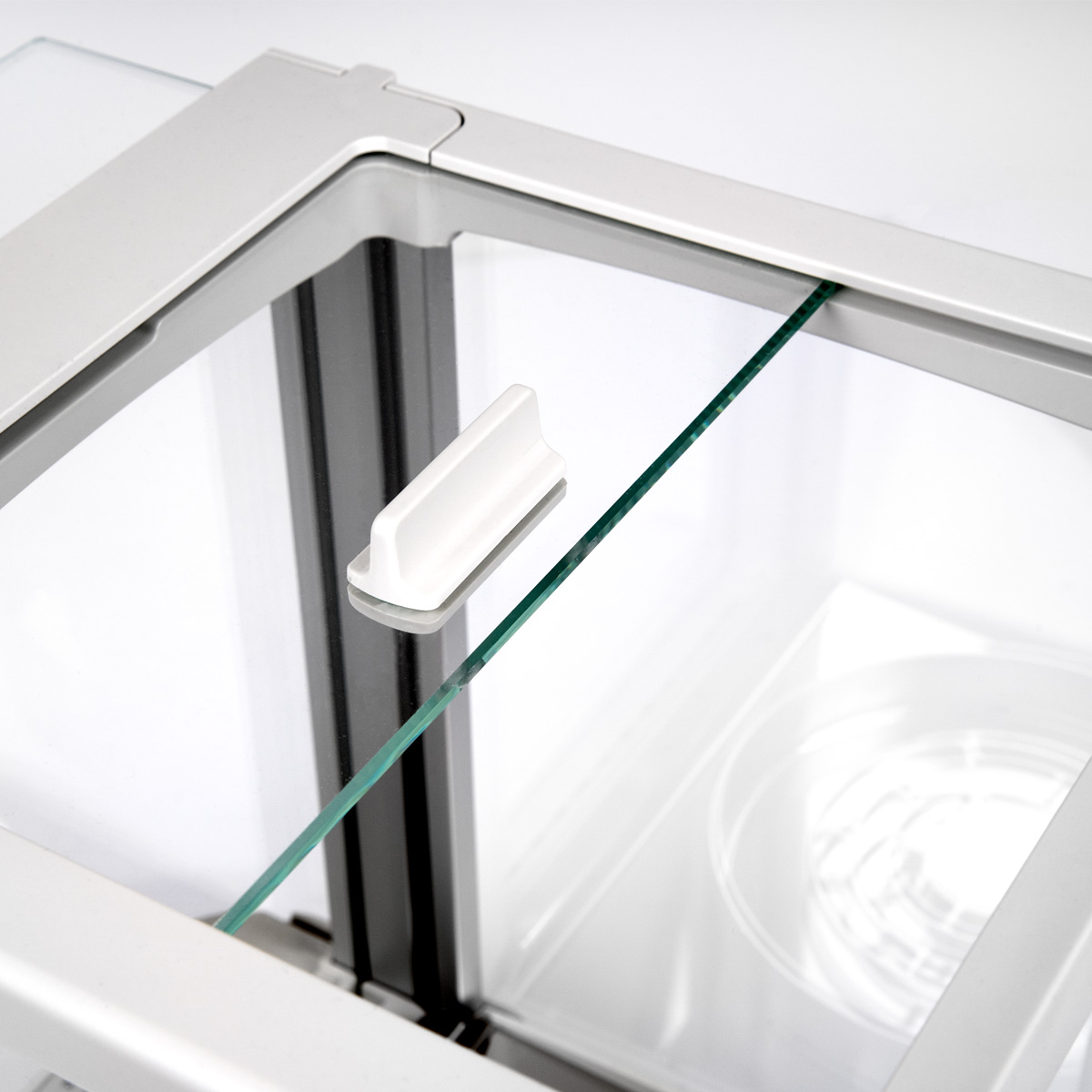

Grâce au système DUAL-CLICK, démontage et montage de la chambre de pesée se déroule sans l'utilisation d'outils et la structure spéciale des guides en verre dans la chambre de pesée (pas de bords) facilite grandement la propreté de l'appareil.

Des solutions de conception innovantes augmentent la durabilité et la fiabilité des balances en fonctionnement à long terme.

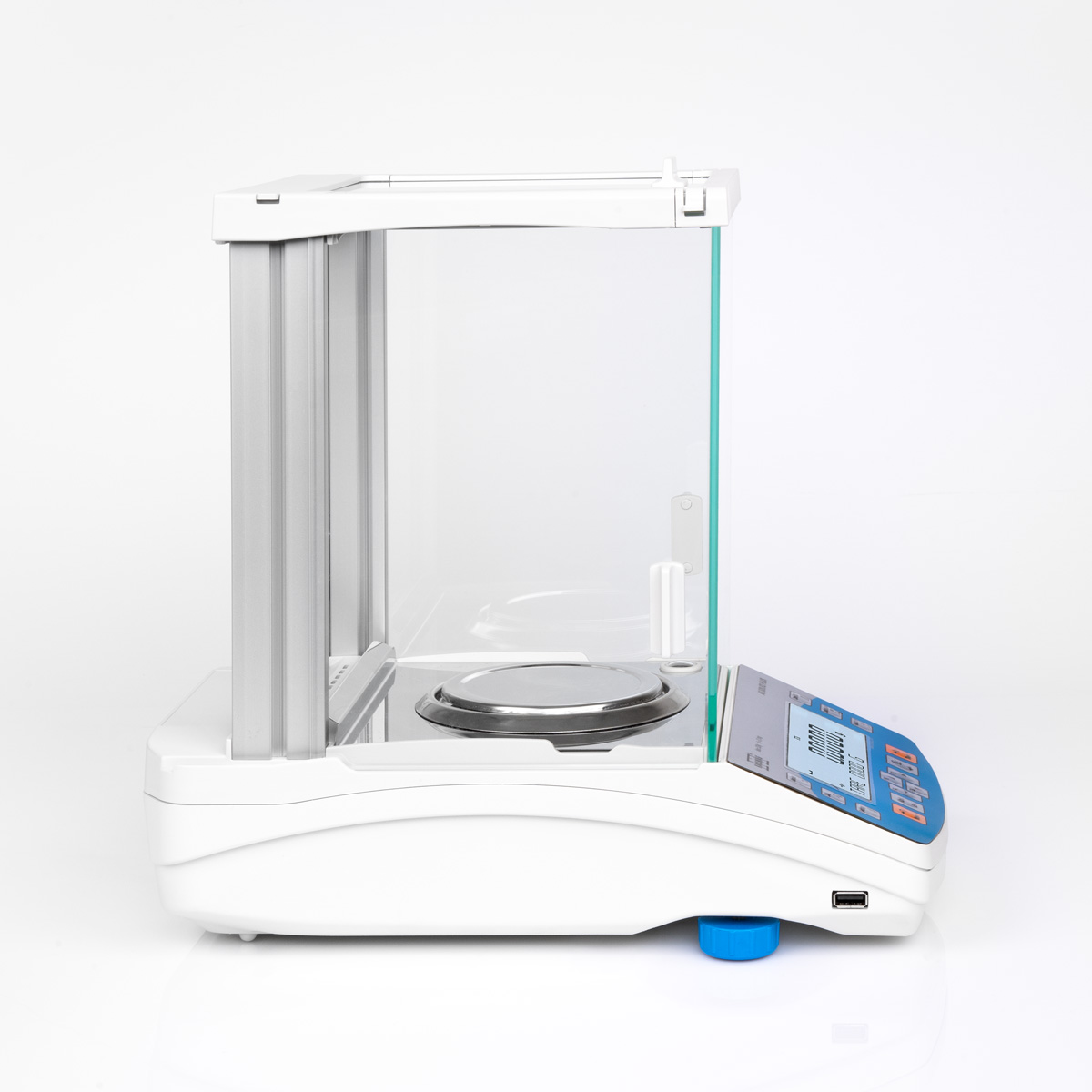

Système de nivellement

Le réglage du niveau de la balance a été simplifié et facilité en limitant le nombre de points d'appui réglables à deux.

Fonctionnement intuitif

- Base de données - accès direct aux bases de données,

- Fonction - accès direct aux fonctions de base,

- F1 à F4 - touches de fonction programmables et touches de navigation dans les menus.

La modernisation du système de calibrage interne garantit la précision des indications dans des conditions extrêmement défavorables.

Protection des données

Mémoire ALIBI

Base de données

- UTILISATEURS - 100 différents utilisateurs,

- PRODUITS - 1000 différents produits,

- TARES - 100 différentes masses des emballages,

- PESAGES - 5 000 mesures suivantes,

- ALIBI - 100 000 mesures suivantes.

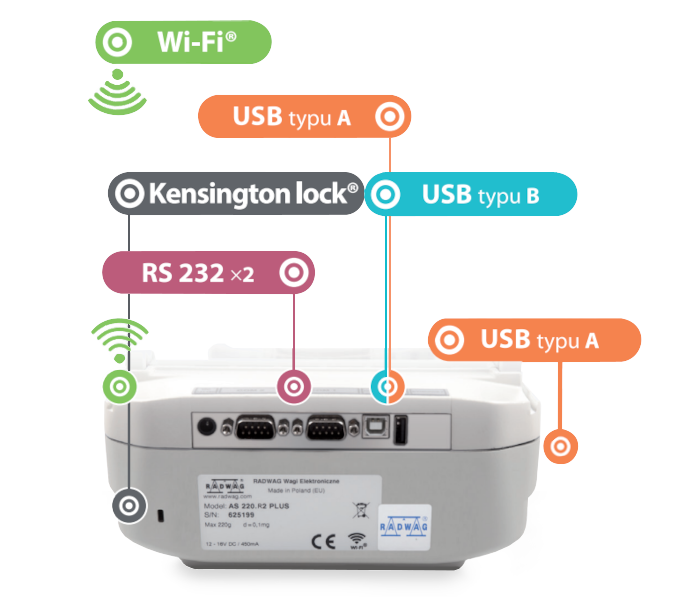

Interfaces de communication

Learn about the use and maintenance of stainless steel products:

Acier inoxydable dans les balances RADWAG

Wi-Fi® est une marque déposée de Wi-Fi Alliance®.

Extra payment

Extra payment

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Deutsch

Deutsch English

English Español

Español Italiano

Italiano Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文