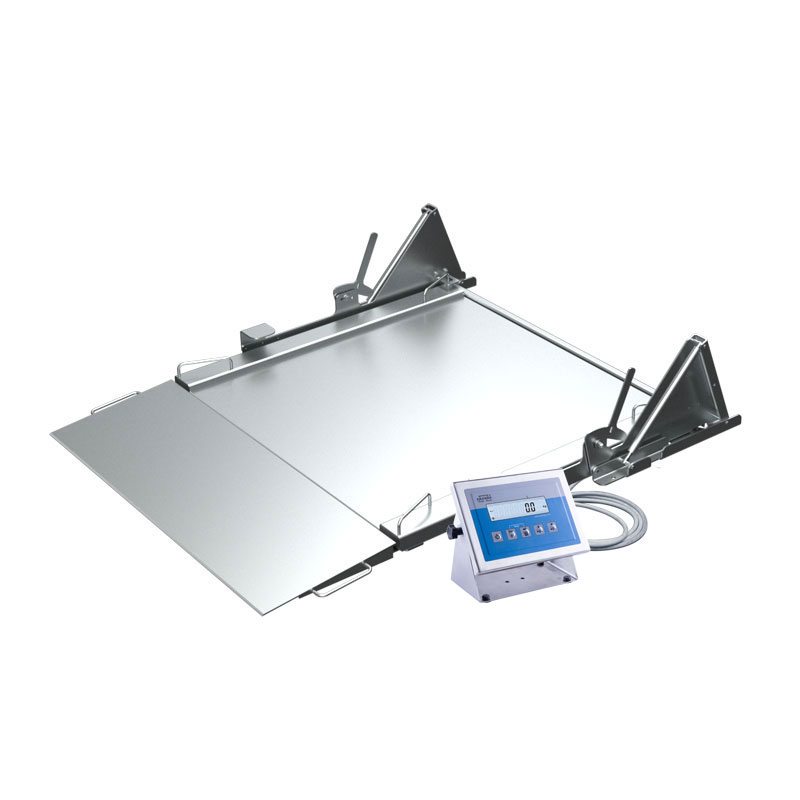

Está equipada en el nuevo sistema LD4N permite elevar la plataforma con seguridad para la limpieza. El sistema no requiere esfuerzo físico ni equipo adicional. Al bajar la plataforma, la balanza está lista para llevar a cabo la medición. No hay necesidad de recalibración.

Las balanzas de rampa están fabricadas de acero inoxidable OH18N9 y tiene un indicador PUE H315 de acero inoxidable. Por pedido especial, es posible fabricar básculas de rampa en versión mejorada de acero inoxidable anticorrosión.

La longitud del cable que conecta el indicador a la plataforma - 3m.

La balanza está disponible en versión de doble rango con recargo.

Learn about the use and maintenance of stainless steel products:

Stainless Steel in RADWAG products. Standard and special applications

Extra payment

Extra payment

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Deutsch

Deutsch English

English Français

Français Italiano

Italiano Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文