Precision of WLC balances

Precision not just in the name

The power of steel

It has been with us for years, and will stay for a long time to come

Internal power

Time counts

WLC 6/A2/C/2 Precision Balance

| Maximum capacity [Max] | 6 kg |

| Minimum load | 5 g |

| Readability [d] | 0.1 g |

| Verification unit [e] | 1 g |

| Tare range | -6 kg |

| Repeatability | 0.15 g |

| Linearity | ±0.2 g |

| Stabilization time | 3 s |

| Adjustment | internal (automatic)

|

| OIML Class | II

|

| Leveling system | manual

|

| Display | LCD (backlit)

|

| Weighing pan dimensions | 195×195 mm |

| Packaging dimensions | 430×270×190 mm |

| Net weight | 3.6 kg |

| Gross weight | 4 kg |

| Protection class | IP 43

|

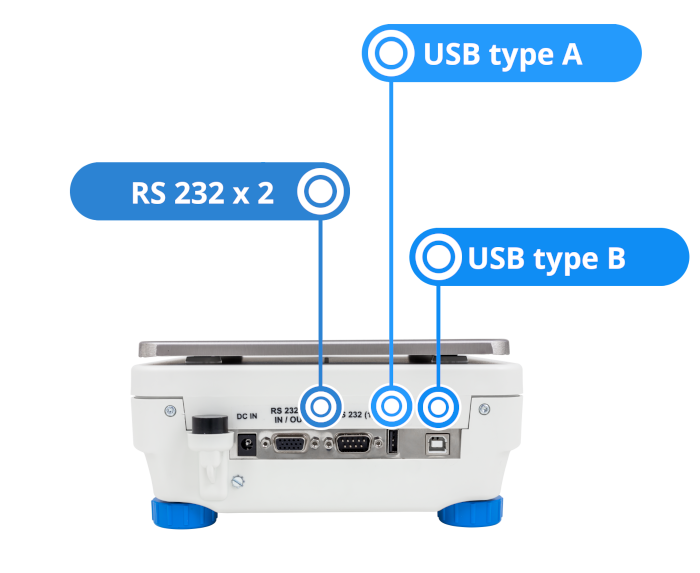

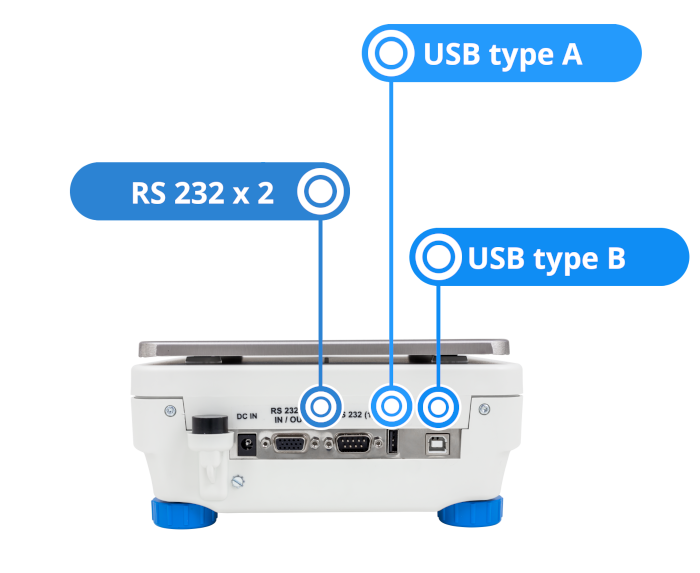

| Communication interface | 2×RS232, USB-A, USB-B

|

| Power supply | Adapter: 100 – 240V AC 50/60Hz 0.6A; 12V DC 1.2A

|

| Operation time on batteries | 15 h (average time)

|

| Operating temperature | +15 — +30 °C |

| Relative humidity | 10% — 85% RH no condensation

|

Extra payment

Extra payment