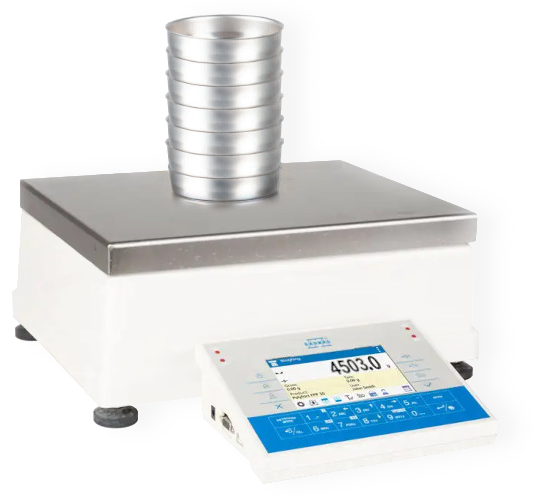

Präzisionswaage C32.35.PM

MONO

BLOCK® -Technologie- Die Möglichkeit, Lasten bis zu 120 kg auf einer großen Waagschale mit hoher Genauigkeit und guter Wiederholbarkeit zu wiegen,

- minimaler Exzentrizitätsfehler über den gesamten Bereich,

- schnelle und stabile Messung (erreichbar innerhalb von 1 Sekunde),

- Stabilität der Parameter über die Zeit und während des Transports,

- an die Genauigkeit der Waage angepasste Abmessungen der Wägefläche

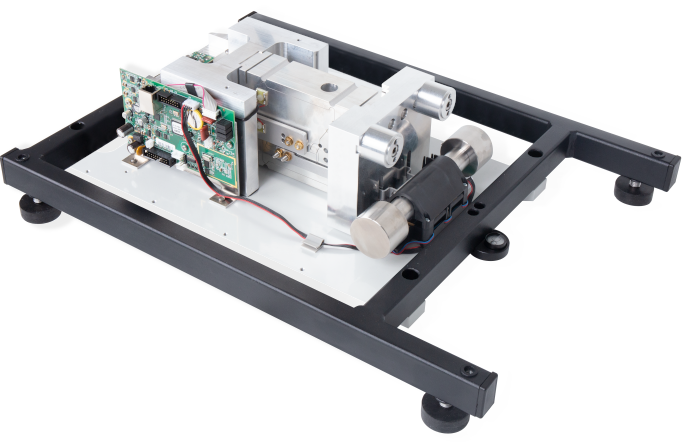

MONO

BLOCK® -Technologie basiert.Die PM-Waagen bieten außerdem

- robuste Konstruktion auf der Basis eines größeren und höheren Monoblocks

- eingebautes 4-Punkt-Überlastungsschutzsystem

- Schutzart IP 43

- interne Justierung

- 5" Farbdisplay

- einfache Inbetriebnahme, intuitive Bedienung und Ergonomie im Betrieb

Anwendung

Erfahren Sie mehr über die Verwendung und Pflege von Edelstahlprodukten:

Rostfreier Stahl in RADWAG-Produkten. Standard- und Spezialanwendungen

Extra payment

Extra payment

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin English

English Español

Español Français

Français Italiano

Italiano Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文