Balanza de precisión PS 1000.R1

New PS.R1 balances

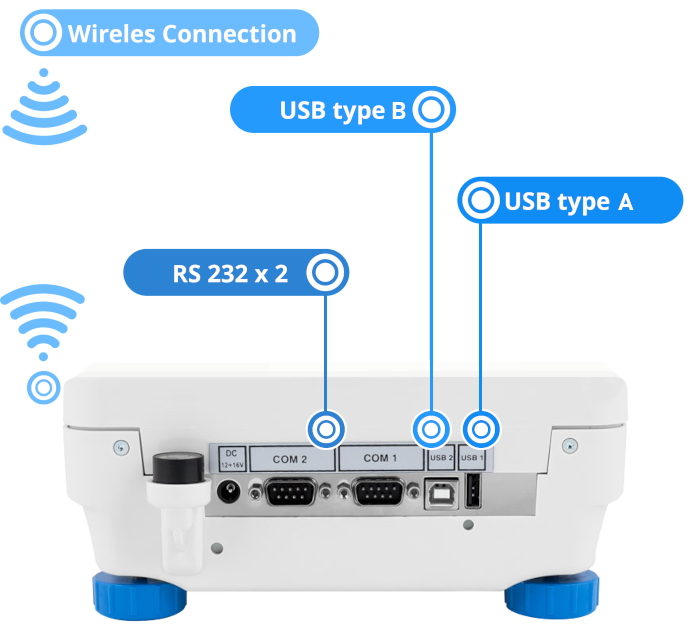

PS.R1 balances feature several communication interfaces: 2 x RS 232, type A USB, type B USB and optional Wireless Connection.

The balance may cooperate with computer by means of USB interface supposing a supplementary software has been installed (respective driver). The said driver may be downloaded from RADWAG website – SOFTWARE link or SUPPORT section.

The housing is made of plastic, and the pan is made of stainless steel. The balances have a possibility to weigh products out of the pan (under hook weighing) - the load hangs under the pan.

Databases in R Series Balances

The data is registered in 5 databases:

- users (up to 10 users),

- products (up to 1000 products),

- weighments (up to 5000 weighments),

- tares (up to 100 tares),

- ALIBI memory (up to 100 000 weighments).

Quick access to information

- Database – a direct access to databasis

- Function - a direct access to the basic functions

- F1 to F4 – programmable function and navigation keys on the menu

Learn about the use and maintenance of stainless steel products:

Stainless Steel in RADWAG products. Standard and special applications

Albanian

Albanian Danish

Danish Nederlandse

Nederlandse Estonian

Estonian Finnish

Finnish Hungarian

Hungarian Icelandic

Icelandic Kazakh

Kazakh Latvian

Latvian Lithuanian

Lithuanian Macedonian

Macedonian Norwegian

Norwegian Portuguese

Portuguese Romanian

Romanian Russian

Russian Slovak

Slovak Slovenian

Slovenian Swedish

Swedish Ukrainian

Ukrainian Serbian

Serbian Montenegrin

Montenegrin Deutsch

Deutsch English

English Français

Français Italiano

Italiano Polski

Polski Türkiye

Türkiye Česky

Česky USA

USA 中文

中文